Magnets! We encounter them every day, from holding notes on our fridge to powering the speakers in our phones. But have you ever stopped to think about what these magnets are made of? This article is your comprehensive guide, offering an A-Z look at common magnetic materials, explaining their properties, uses, and why they are essential in various industries. Consider this your friendly roadmap to navigating the world of magnetism! I’ll cover everything from the familiar ferrite to the powerful neodymium, ensuring you understand the fascinating science behind these materials. So, let’s dive in!

What Exactly is a Magnetic Material?

Before we jump into our A-Z list, it’s crucial to understand what makes a material "magnetic." Magnetic materials are substances that are attracted to magnets or capable of becoming magnets themselves. This attraction stems from the alignment of electron spins within the material. Certain materials have unpaired electrons, creating a net magnetic dipole moment. When these dipoles align, the material exhibits magnetic properties. Magnetic properties are determined by the electron orbital structure of a material and include permeability, coercivity, saturation, and remanence.

Think of it like aligning tiny compass needles within a material. If they all point in the same direction, you have a strong magnet. If they are randomly oriented, the material might not be visibly magnetic. Iron, nickel, and cobalt are classic examples of ferromagnetic materials that readily exhibit this alignment.

The strength of a magnet is also affected by various factors, including temperature, density, and the way material is processes.

Alnico: The Original Powerhouse – Where Did It Go?

Alnico magnets were once the king of permanent magnets. They are a family of iron alloys which, in addition to iron, are composed primarily of aluminum (Al), nickel (Ni), and cobalt (Co), hence the name Al-Ni-Co. The main development of alnico magnets began in the 1930s, when it was found that heat treatment in a magnetic field could dramatically improve the material’s magnetic properties.

Alnico magnets are known for their excellent temperature stability, maintaining their magnetic strength even at relatively high temperatures (up to 500 degrees Celsius). They are also highly resistant to corrosion. However, they have a relatively low coercivity (resistance to demagnetization) compared to newer magnetic materials. This means they are susceptible to being demagnetized if exposed to strong opposing magnetic fields. Typical applications included electric motors, guitar pickups, and sensors. Alnico magnets are also often used in separation applications needing high-temperature tolerances.

Ceramic Magnets (Ferrites): Are They Really Just for Fridge Magnets?

Ceramic magnets, also known as ferrite magnets, are composed primarily of iron oxide (Fe2O3) and barium or strontium carbonate. These are some of the most common and inexpensive types of permanent magnets. They are characterized by their high coercivity, good resistance to demagnetization, and excellent corrosion resistance. This comes at the expense of energy density.

One of their strengths is their low cost. However, they also have low energy density compared to alnico and rare earth magnets, which limits their use in applications needing very strong magnets. You see them in loudspeakers, DC motors, magnetic separators, and, yes, your refrigerator magnets. They are also very commonly used in magnetic toys and teaching tools because of their affordability and durability. There are two types of ceramic material, hard and soft. Hard magnet types are permanent, and soft types are used in high-frequency applications.

Ceramic magnets are made with a sintering process, compacting the materials at high heat. This process create magnets with hard material properties.

Cobalt: More Than Just a Magnetic Metal?

Cobalt itself is a ferromagnetic metal, meaning it can exhibit a permanent magnetic moment. However, it’s rarely used in its pure form for magnets because it’s relatively expensive and has lower magnetic strength than other options like neodymium. Its main use in magnetism is as an alloying element in Alnico and Samarium Cobalt magnets.

Cobalt’s contribution to these alloys is significant. It helps to increase the Curie temperature (the temperature above which a material loses its ferromagnetism) and improve the magnetic strength and coercivity. Cobalt is a strategic metal, and so a lot of effort is placed at reducing the use of Cobalt in magnetic alloys. Besides magnets, Cobalt is used in the production of medical devices, in electroplating, and increasingly in batteries.

Electromagnets: Temporary Powerhouses – How Do They Work?

Electromagnets are magnets that generate a magnetic field when an electric current flows through a wire coiled around a ferromagnetic core (usually iron). The strength of the magnetic field is proportional to the current flowing through the wire and the number of turns in the coil. Unlike permanent magnets, electromagnets can be turned on and off at will.

This on/off capability makes them extremely versatile. They’re used in a vast array of applications, including electric motors, generators, transformers, magnetic levitation (maglev) trains, and medical imaging equipment like MRI machines. Electromagnets are also fundamental in various industrial applications, such as lifting heavy steel objects in scrap yards and controlling valves in hydraulic systems. The use of Electromagnets are expanding rapidly and are becoming more and more sophisticated.

We can use superconductors to maintain the current in a strong, non-decreasing magnetic field using an Electromagnet.

Ferrites (Soft): What Makes Them Different From Ceramic Magnets?

While we mentioned ceramic magnets earlier, it’s important to distinguish between "hard" ferrites (ceramic magnets) and "soft" ferrites. Soft ferrites are iron-containing ceramic compounds that exhibit high permeability and low coercivity. This means they are easily magnetized and demagnetized.

The main advantage of soft ferrites is their high electrical resistivity, which reduces eddy current losses at high frequencies, which are circular electrical currents induced within conductors by magnetic fields. This makes them ideal for applications in inductors, transformers, and other electronic components operating at high frequencies. So, while ceramic magnets are used in speakers and motors, soft ferrites are essential in the power supplies of your electronic devices.

Soft ferrites are found in applications like induction loops in roads and magnetic cores for inductors and transformers.

Gadolinium: Is This Rare Earth Element Primarily for MRI Machines?

Gadolinium is a rare earth element that is weakly ferromagnetic at room temperature and becomes strongly ferromagnetic below its Curie temperature (around 20°C). However, in its pure form, it’s not commonly used to create permanent magnets.

Its primary use is in medical imaging, particularly in MRI (Magnetic Resonance Imaging) contrast agents. Gadolinium-based contrast agents enhance the visibility of internal organs and tissues, allowing doctors to diagnose various conditions more accurately. Gadolinium is also used in neutron radiography and some magneto-optical discs. Gadolinium products for MRI usage are regulated due to the health challenges created by the material.

Iron: The Backbone of Magnetism – Why Not Used Alone?

Iron is the foundation of many magnetic materials This is because its electron structure leaves it open to unpaired electron spin. While you can magnetize pure iron, it doesn’t hold that magnetization very well. It is considered to be magnetically ‘soft’, which means the material will readily take on the magnetic properties of its surroundings, but then easily goes back to having neutral magnetism. The presence of other elements or substances, or changes to temperature, pressure or electricity may impact magnetism.

That’s why it’s usually alloyed with other elements like aluminum, nickel, and cobalt (in Alnico magnets) or iron oxide (in ceramic magnets) to improve its magnetic properties – specifically to increase the coercivity, or resistance to demagnetization. Essentially, it forms the backbone, or structure of more powerful magnets.

Kerr Effect Materials: The Future of Magnetic Storage?

Kerr effect materials, also known as magneto-optical materials, exhibit the Kerr effect. This effect occurs when linearly polarized light is reflected from a magnetized surface, causing a rotation of the polarization plane. The amount of rotation is dependent on the magnetization of the material.

This property is exploited in magneto-optical data storage, where lasers are used to write and read data on magnetic disks. Kerr effect materials offer high data storage densities and fast access times. While not as prevalent as other storage technologies, they remain an important area of research and development for the next generation of data storage solutions. Scientists are actively working on new materials that take advantage of the Kerr Effect.

Lanthanides: What Special Properties Makes Them Unique?

Lanthanides, also known as rare earth elements, are a group of 15 elements with atomic numbers ranging from 57 (Lanthanum) to 71 (Lutetium). Several lanthanides, including neodymium, samarium, and dysprosium, possess unique magnetic properties due to their electron configurations.

These elements are crucial for creating high-performance permanent magnets like neodymium magnets and samarium-cobalt magnets. Their unique electronic structures allow for strong magnetic moments and high coercivity, resulting in magnets that are significantly stronger than traditional alnico or ferrite magnets.

Mu-Metal: Shielding Sensitive Electronics – How Effective Is It?

Mu-Metal is a nickel-iron alloy known for its exceptionally high magnetic permeability. High permeability means that it can easily conduct magnetic flux. The purpose makes it ideal for shielding sensitive electronic equipment from external magnetic fields.

Mu-metal does this by providing a low-reluctance path for magnetic field lines, diverting them away from the shielded component. It’s used in transformers, magnetic shields, and tape recorder heads. Mu-metal is very effective, but also very sensitive to deformation, which means caution during handling.

Neodymium Magnets (NdFeB): The Superstars – Where Are They Used?

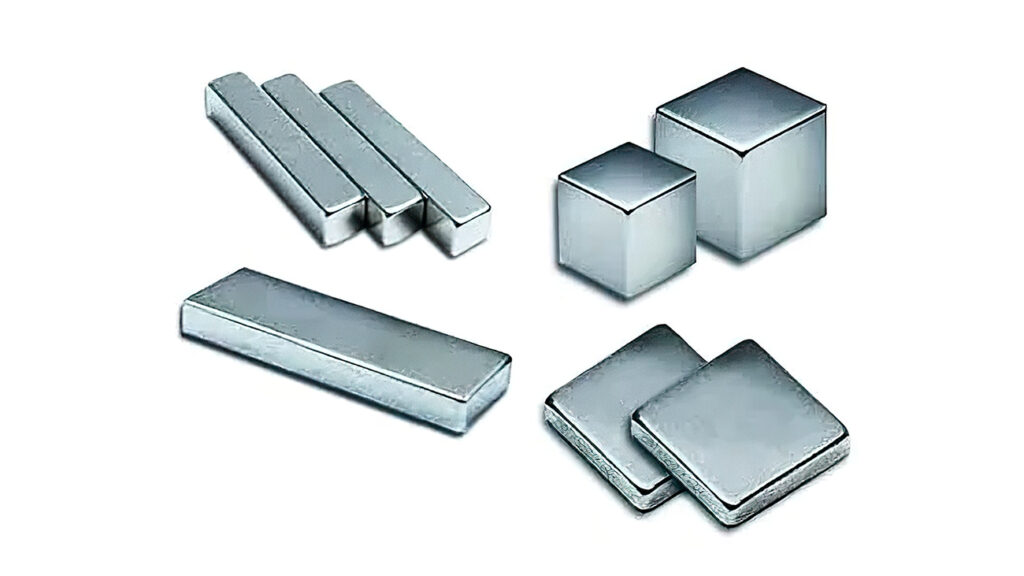

Neodymium magnets, also known as NdFeB magnets, are the strongest type of permanent magnet commercially available. They are composed of an alloy of neodymium, iron, and boron. Neodymium magnets boast extremely high magnetic strength (high energy density) and coercivity.

This makes them ideal for applications where a strong, compact magnet is needed. You’ll find them in everything from hard disk drives and electric motors to wind turbines and magnetic jewelry. They are essential components in smartphones, headphones, and electric vehicles. However, they degrade at high temperature, and oxidize in air, so they require coatings.

The rapid growth of electric vehicle technology has driven demand for neodymium magnets significantly and has become a point of geopolitical tension.

Oxide Magnets: (See Ceramic magnets)

Permalloy: A Magnetically Soft Material

Permalloy is another nickel-iron alloy known for its high magnetic permeability, similar to Mu-Metal. It is primarily used in magnetic cores and shielding applications. Permalloy offers excellent soft magnetic properties, but Mu-Metal is superior in coercivity, and so Permalloy is sometimes preferred in applications such as magnetic tape recording heads and specialized transformers.

Rare-Earth Magnets: What Makes Them So Powerful?

Rare-earth magnets, encompassing both neodymium and samarium-cobalt magnets, are characterized by their exceptional strength compared to other types of permanent magnets. This stems from the unique electronic structure of the rare-earth elements.

The combination of high magnetic moment and high coercivity makes them indispensable in many modern technologies, however, they come with a high cost, and so they are only used where the cost can be justified. From electric motors and generators to medical devices and consumer electronics.

Samarium Cobalt Magnets (SmCo): The High-Temperature Champion?

Samarium cobalt magnets (SmCo) are another type of rare-earth magnet, composed of an alloy of samarium and cobalt. They don’t quite compete with the material properties of Neodymium, but they have exceptional characteristics.

While not quite as strong as neodymium magnets, they shine in high-temperature applications. Samarium cobalt magnets maintain their magnetic strength at temperatures up to 300 degrees Celsius, making them ideal for use in electric motors operating in harsh environments, aerospace applications, and high-performance sensors.

Transition Metals: Iron, Nickel, and Cobalt – The Magnetic Trio?

The transition metals, specifically iron, nickel, and cobalt, are ferromagnetic elements. This means that when they are made into magnets, the materials exhibit the highest level of permanent magnetism. Their electronic structure allows them to align their electron spins, creating a strong net magnetic moment.

These three elements are the foundation of many magnetic alloys. While iron is the most abundant and widely used, nickel and cobalt are often added to improve magnetic properties like coercivity, temperature stability, and corrosion resistance.

FAQs About Magnetic Materials

Here are some frequently asked questions about magnetic materials.

- What is the strongest magnetic material? Neodymium magnets (NdFeB) are currently the strongest commercially available permanent magnet.

- Are all metals magnetic? No, only a few metals like iron, nickel, and cobalt are ferromagnetic. Most other metals are either paramagnetic or diamagnetic.

- How does temperature affect magnets? Increasing temperature can weaken or demagnetize magnets. Each magnetic material has a Curie temperature above which it loses its ferromagnetism.

- Why are rare earth elements important for magnets? Rare earth elements like neodymium and samarium have unique electronic structures that enable the creation of very strong, high-performance permanent magnets.

- Can magnets lose their strength over time? Yes, magnets can weaken over time due to factors like temperature, exposure to demagnetizing fields, and physical shock. This process is called "aging."

- What is the difference between hard and soft magnetic materials? Hard magnetic materials have high coercivity and are difficult to demagnetize, making them suitable for permanent magnets. Soft magnetic materials have low coercivity and are easily magnetized and demagnetized, making them suitable for applications like transformer cores.

Conclusion: Key Takeaways

This guide has provided an overview of common magnetic materials, highlighting their key properties and applications. Remember these points:

- Magnetic materials are essential in modern technology, from everyday devices to industrial applications.

- Neodymium magnets are the strongest, but other materials like ferrite and Alnico have unique advantages.

- Temperature and other factors can affect magnetic strength.

- Rare earth elements are crucial for high-performance magnets.

- Understanding the properties of different magnetic materials is key to selecting the right material for a specific application.

Magnetic fields and materials play a massive role in the current and future technological landscape. As technology progresses, so will magnetic science, so there is a vast scope for this fascinating field to grow.