# Beyond the Bar: A Deep Dive into the Diverse Shapes of Magnets and Their Applications

Magnets! We see them everywhere, from holding notes on our refrigerators to powering massive industrial machines. But did you know that the familiar bar magnet is just one small part of a much larger, more fascinating world of magnetic shapes? This article explores the diverse shapes magnets can take, how those shapes influence their properties, and the surprising applications where you’ll find them. Get ready to discover the magnetic world beyond the bar!

## Are All Magnets Just Rectangular Bars? Unveiling the Variety of Magnetic Shapes

No way! While the bar magnet might be the most recognizable, the world of magnets boasts a stunning variety of shapes. These shapes aren’t arbitrary; they’re carefully engineered to optimize the magnetic field for specific purposes. From horseshoe shapes designed for maximum strength in a concentrated area to intricate geometries used in advanced technologies, the shape of a magnet plays a crucial role in its performance. Just like how a chef uses different knives for different tasks, engineers choose specific magnet shapes for optimal performance.

Think about it: a powerful magnet used in a generator spinning at high speeds needs a very different shape and construction than a small button magnet used to keep a child’s toy closed. The shape directly influences the magnet’s ability to withstand centrifugal forces, resist demagnetization, and efficiently channel its magnetic field.

## What Makes Horseshoe Magnets So Powerful? Concentrating Magnetic Fields

Have you ever wondered why horseshoe magnets seem stronger than bar magnets of similar size? The secret lies in their unique shape, which concentrates the magnetic field into a smaller area between the poles. This concentration creates a powerful magnetic force, making horseshoe magnets ideal for lifting heavy objects and performing tasks requiring a strong, localized magnetic field.

The U-shape of the horseshoe essentially brings the north and south poles closer together. This significantly reduces the magnetic flux leakage – the portion of the magnetic field that spreads out and dissipates rather than contributing to the force between the poles. By minimizing leakage, the horseshoe magnet maximizes the magnetic field intensity in the gap, resulting in a stronger pull.

## Ring Magnets: More Than Just Pretty Shapes – Exploring Their Applications

Ring magnets, with their central hole, are incredibly versatile and find applications in various devices, from loudspeakers and motors to magnetic sensors and bearings. The shape allows for convenient mounting on shafts or axles, enabling rotational movement within a magnetic field.

One of the key advantages of a ring magnet is its consistent magnetic field distribution around the central axis. This makes it well-suited for applications requiring smooth and predictable rotational forces. For example, in a loudspeaker, a ring magnet surrounds the voice coil, providing a uniform magnetic field that interacts with the current in the coil to produce sound waves.

## Cylinder Magnets: Small Size, Big Impact – Using Cylindrical Shapes Effectively

Cylinder magnets, with their simple yet effective shape, are commonly used in sensors, reed switches, and even some types of electric motors. Their compact size and concentrated magnetic field make them valuable components in applications where space is limited.

The cylindrical shape offers a good balance between magnetic strength and ease of manufacturing. They can be easily magnetized along their axis, creating a strong magnetic field at each end. Their small size allows them to be incorporated into small devices and sensors. For instance, in a reed switch, a small cylindrical magnet brought close to two conductive reeds causes them to close, completing an electrical circuit. This makes them ideal for position sensing and control applications.

## Spherical Magnets: Point Contact, Maximum Flexibility – Applications in Medicine and Robotics

Spherical magnets, shaped like perfect spheres, offer unique advantages in applications requiring point contact and rotational freedom. They are increasingly used in medical devices, robotics, and even magnetic stirrers.

Their smooth, rounded surface allows them to easily roll and manipulate objects in a confined space. For example, in some medical applications, tiny spherical magnets are used to guide catheters through blood vessels or to deliver drugs directly to targeted tissues. Their rotational freedom also makes them ideal for creating precise and controlled movements in robotic systems.

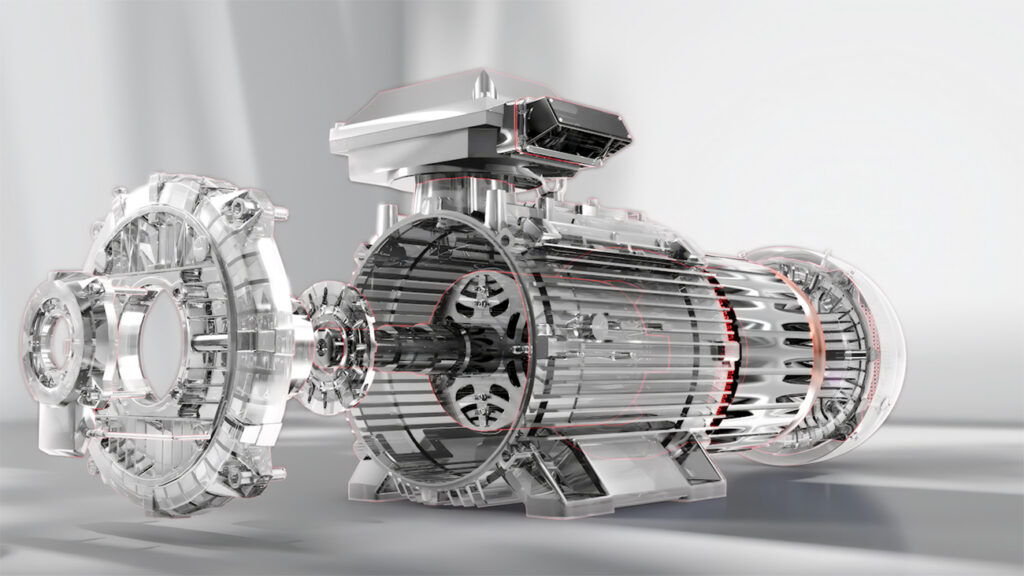

## Block Magnets: Versatile and Powerful – Building a Better Motor

Block magnets are workhorses in various applications, including electric motors, generators, and magnetic separators. Their rectangular shape allows for easy integration into complex assemblies, and their large surface area provides for a strong magnetic field.

The block shape provides stability and a large surface area for maximizing magnetic flux. This is particularly important in electric motors and generators, where multiple block magnets are arranged around a rotor to generate rotational force. In magnetic separators, block magnets are used to separate ferrous materials from non-ferrous materials in recycling plants and mining operations.

## How Do Pot Magnets Differ? Strength in a Steel Shell

Pot magnets are unique in that they encase a magnet (typically neodymium) within a steel shell. This configuration significantly amplifies the holding force by directing the magnetic flux to the exposed face. They’re commonly used for holding, lifting, and retrieving metal objects.

The steel pot acts as a magnetic flux concentrator, channeling nearly all of the magnetic field lines towards the exposed surface. This drastically reduces the magnetic field leakage and concentrates the force in a single direction. This makes pot magnets significantly stronger than exposed magnets of the same size, particularly when attached to a flat, ferromagnetic surface.

*A study by Magnet Expert Ltd. showed that a pot magnet can have a holding force up to 30 times greater than a similarly sized bare magnet.*

## Flexible Magnets: Bending and Shaping Magnetic Fields

Flexible magnets, made from a mixture of ferrite powder and a flexible binder, are incredibly versatile and can be easily cut, bent, and shaped to fit specific applications. You’ll find them in refrigerator magnets, promotional items, and even some types of seals.

The combination of flexible binder and magnetic material results in a magnet that is easy to work with while still retaining reasonable magnetic properties. While not as strong as neodymium magnets, flexible magnets offer the advantage of being readily customizable to any shape or size.

**Table: Common Magnet Shapes and Their Applications**

| Magnet Shape | Common Applications | Key Advantages |

|—|—|—|

| Bar Magnet | Educational demonstrations, compasses | Simple, easy to understand |

| Horseshoe Magnet | Lifting heavy objects, magnetic latches | Concentrated magnetic field |

| Ring Magnet | Loudspeakers, motors, sensors | Consistent magnetic field distribution |

| Cylinder Magnet | Sensors, reed switches, small motors | Compact size, concentrated field |

| Spherical Magnet | Medical devices, robotics | Point contact, rotational freedom |

| Block Magnet | Motors, generators, magnetic separators | Versatile, strong magnetic field |

| Pot Magnet | Holding, lifting, retrieving objects | Amplified holding force |

| Flexible Magnet | Refrigerator magnets, promotional items | Customizable, flexible |

## What is Anisotropic vs. Isotropic Magnetization and How Does It Affect Shape Choice?

The terms anisotropic and isotropic refer to the directionality of magnetization within a magnet. Isotropic magnets can be magnetized in any direction after they are manufactured. Anisotropic magnets, however, have a preferred direction of magnetization during the manufacturing process, resulting in stronger magnetic properties in that direction.

The choice between anisotropic and isotropic magnets often influences the shape selection. For applications requiring maximum magnetic strength in one direction, anisotropic magnets are preferred, often in simple shapes like blocks or cylinders that align with the preferred magnetization direction. Isotropic magnets offer more flexibility in magnetization patterns but generally have weaker magnetic properties, making them suitable for flexible magnets and applications where complex shapes or multi-pole magnetization is desired.

## Case Study: The Evolution of Magnet Shapes in Electric Vehicles

The electric vehicle (EV) industry provides a compelling case study of how magnet shape selection has evolved. Early EV motors often utilized radially magnetized ring magnets for their rotor. However, as manufacturers sought increased power density and efficiency, they transitioned to segmented block magnets arranged in specific patterns to optimize the magnetic flux within the motor. More recent innovations explore Halbach arrays – unique arrangements of block magnets designed to create exceptionally strong and uniform magnetic fields – to push performance boundaries further. What we see is that the choice of the shape helps get increase performance and density.

Now, let’s address some frequently asked questions!

**FAQ Section**

**Why are neodymium magnets so popular compared to other types of magnets?**

Neodymium magnets are incredibly popular due to their exceptional strength-to-size ratio. They offer a significantly stronger magnetic field than ferrite or alnico magnets of the same size, making them ideal for applications where space is limited or a high magnetic force is required. They are much more expensive to manufacture.

**Can magnets lose their magnetism over time?**

Yes, magnets can lose their magnetism over time through a process called demagnetization. This can be caused by exposure to high temperatures, strong opposing magnetic fields, or mechanical stress. The rate of demagnetization depends on the type of magnet, its shape, and the environmental conditions it experiences.

**Are some magnet shapes better at resisting demagnetization than others?**

Yes, some magnet shapes are inherently more resistant to demagnetization than others. For example, pot magnets, with their steel shell, offer excellent protection against demagnetization. Similarly, magnets with a high length-to-diameter ratio are generally more resistant to demagnetization than short, squat magnets.

**How are magnets of different shapes manufactured?**

The manufacturing process varies depending on the magnet material and shape. Ferrite magnets are typically made by sintering (heating compressed powder), while neodymium magnets are often made through powder metallurgy. Flexible magnets are made by mixing magnetic powder with a flexible binder and then extruding or calendering the mixture into sheets or strips. The precise details depend on the shape.

**What safety precautions should I take when handling strong magnets?**

Strong magnets can be dangerous if mishandled. They can pinch skin, crush fingers, and damage electronic devices. Always handle strong magnets with care, keep them away from electronic devices, and use appropriate safety equipment, such as gloves and eye protection.

**Can I magnetize a regular piece of metal?**

Yes, you can magnetize a ferromagnetic material (like iron or steel) by exposing it to a strong magnetic field. One common method is to stroke the metal repeatedly in one direction with a strong magnet, aligning the magnetic domains within the metal. However, the resulting magnetism is often temporary and will eventually fade away.

**Conclusion**

Exploring the diverse shapes of magnets reveals a fascinating world of engineering and innovation. Each shape offers unique advantages and disadvantages, making them suitable for a wide range of applications. From the simple bar magnet to the complex Halbach array, the shape of a magnet plays a crucial role in its performance. By understanding the properties and applications of different magnet shapes, we can unlock even more possibilities for harnessing the power of magnetism.

Here are the key takeaways:

* Magnets come in various shapes, each optimized for specific applications.

* Horseshoe magnets concentrate magnetic fields for increased strength.

* Ring magnets are ideal for rotational applications.

* Cylinder magnets excel in compact sensors and switches.

* Spherical magnets offer flexibility in medical devices and robotics.

* Block magnets are workhorses in motors, generators, and separators.

* Pot magnets amplify holding force through a steel shell.

* Flexible magnets provide versatility and customizability.

* Selecting anisotropic or isotropic magnets greatly influence magnetization.

* Consider the case study on electric vehicle magnetization on types.

Beyond the Bar: Exploring the Diverse Shapes of Magnets