Cobalt-based magnetic materials are critical components in a wide range of technologies, from high-performance magnets to data storage devices. Their unique properties, including high Curie temperature and magnetocrystalline anisotropy, make them indispensable for applications where performance and stability are paramount. This article delves into the fascinating world of these materials, exploring their classifications, properties, applications, and future prospects. Join me as we unravel the complexities of cobalt-based magnetism and discover why these materials continue to be at the forefront of technological innovation.

What Makes Cobalt-Based Magnetic Materials So Special?

Cobalt, a transition metal, possesses exceptional magnetic properties due to its electronic structure. Its partially filled d-orbitals lead to strong exchange interactions, resulting in high magnetic moments and Curie temperatures. When combined with other elements, it gives rise to a diverse range of materials with tailored magnetic characteristics. Let’s look into the specifics of these materials, which, as you will learn, is a critical part of answering why these materials dominate specific application spaces.

Here are some key aspects to consider:

- High Curie Temperature: This allows for stable magnetic performance at elevated temperatures.

- High Magnetocrystalline Anisotropy: Enables strong resistance to demagnetization.

- Versatility: Can be alloyed with many other elements to tune magnetic properties.

- Widespread Applications: Found in motors, generators, recording media, and more.

What are the Different Classifications of Cobalt-Based Magnetic Materials?

Cobalt-based magnetic materials can be broadly classified based on their composition and magnetic behavior. Understanding these classifications is crucial for selecting the right materials for specific applications. Let’s examine some of the most important categories.

- Cobalt-Iron Alloys (CoFe): Known for their high saturation magnetization and permeability. They are commonly used in transformer cores and magnetic recording heads. For example, CoFe alloys can achieve saturation magnetization levels of 2.4 Tesla.

- Cobalt-Platinum Alloys (CoPt): Exhibit high magnetocrystalline anisotropy, making them suitable for high-density magnetic recording media. They can also be manipulated to achieve the L10 structure.

- Cobalt-Rare Earth Alloys (Co-REM) (e.g., SmCo, PrCo): Offer exceptional magnetic hardness and high energy product, making them ideal for permanent magnets. Samarium Cobalt (SmCo) magnets can operate at temperatures up to 300°C.

- Cobalt-Based Heusler Alloys: A diverse group of materials with complex magnetic behaviors, including ferromagnetism, antiferromagnetism, and half-metallicity.

How Does Magnetocrystalline Anisotropy Impact Performance?

Magnetocrystalline anisotropy refers to the preference of a material’s magnetization to align along certain crystallographic directions. This property is crucial for achieving high coercivity, which is the resistance of a material to demagnetization. Higher anisotropy generally means stronger magnets usable in harsher external fields.

Several factors affect magnetocrystalline anisotropy:

- Crystal Structure: Different crystal structures exhibit different anisotropy. For instances, hexagonal cobalt exhibits strong uniaxial anisotropy.

- Composition: Adding specific elements can enhance or reduce anisotropy.

- Processing: Annealing and other heat treatments can influence the crystal order and control anisotropy.

Why is High Curie Temperature Important for Applications?

The Curie temperature is the temperature above which a ferromagnetic material loses its spontaneous magnetization and becomes paramagnetic. A high Curie temperature ensures that the material maintains its magnetic properties even at elevated temperatures, which is crucial for applications where thermal stability is essential. For instance, high performance motors would lose significant power if the magnets inside of them lost magnetic moment due to high operational temperatures.

Examples where high Curie temperature is vital:

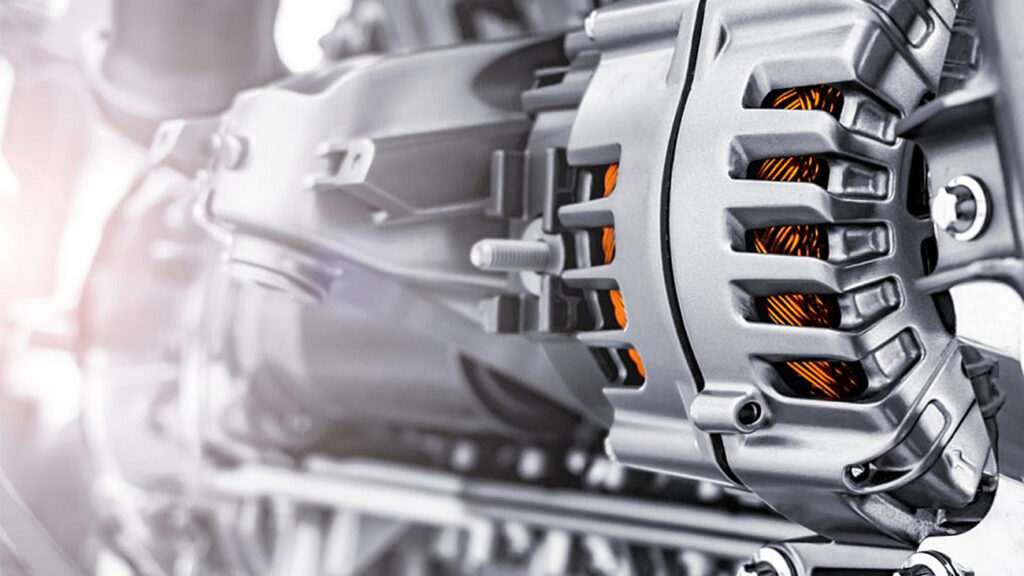

- Electric Motors: Maintaining torque and efficiency at high operating temperatures.

- Generators: Ensuring stable power generation under varying load conditions.

- Sensors: Maintaining accuracy and reliability in harsh environments.

What are the Most Common Applications of Cobalt-Based Magnets?

Cobalt-based magnets find applications across a vast range of industries. Their superior magnetic properties make them indispensable for high-performance devices.

Let’s delve into some key areas:

- Hard Disk Drives (HDDs): CoPt alloys are used for high-density magnetic recording media, enabling increased data storage capacity.

- According to Seagate, cobalt alloy-based recording media can reach areal densities of over 1 TB per square inch.

- Actuators: Required for precision motion control.

- Permanent Magnets (SmCo): Used in high-performance motors, generators, and medical devices.

- Spintronics: Driving advancements in data storage and computing.

- Giant magnetoresistance (GMR) heads featuring cobalt-based layers enable faster and more sensitive reading of data.

How do Cobalt-Based Alloys Compare to Neodymium Magnets?

Neodymium magnets (NdFeB) are the most widely used permanent magnets due to their high energy product. However, cobalt-based magnets offer some advantages over NdFeB, particularly in terms of temperature stability and corrosion resistance.

Here’s a comparative summary:

| Feature | Cobalt-Based Magnets (e.g., SmCo) | Neodymium Magnets (NdFeB) |

|---|---|---|

| Energy Product | Lower | Higher |

| Curie Temperature | Higher | Lower |

| Corrosion Resistance | Better | Poorer |

| Thermal Stability | Superior | Inferior |

| Cost | Higher | Lower |

This comparison shows that cobalt-based magnets are preferred in applications where temperature stability and durability are critical, even if they are more expensive.

What are the Challenges in Manufacturing Cobalt-Based Magnets?

Manufacturing cobalt-based magnets presents several challenges, including the high cost of raw materials, complex alloy compositions, and stringent processing requirements. Overcoming these challenges is essential for reducing costs and improving the widespread adoption of these materials.

Key challenges include:

- Raw Material Cost: The price of cobalt and rare earth elements can fluctuate significantly.

- Alloy Processing: Achieving uniform alloy composition requires precise control over melting, casting, and heat treatment processes.

- Microstructure Control: Optimizing the microstructure for maximum magnetic performance requires careful control of grain size, grain orientation, and phase distribution.

- Resource Scarcity: The limited availability of rare earth elements is a concern for long-term sustainability.

What are Some Emerging Trends in Cobalt-Based Magnetic Research?

Research into cobalt-based magnetic materials is ongoing, with a focus on developing new alloys with enhanced properties and more sustainable manufacturing processes. Some emerging trends include:

- Nanostructured Materials: Exploring the use of nanoparticles and thin films to achieve tailored magnetic properties. Nanocrystalline materials can exhibit enhanced coercivity and energy product.

- Cobalt-Free Magnets: Developing alternative magnetic materials that do not rely on cobalt, which is an expensive and geopolitically sensitive element.

- Additive Manufacturing: Using 3D printing techniques to create magnets with complex geometries and tailored microstructures.

- Computational Materials Design: Employing computational methods to predict and optimize the magnetic properties of new alloys.

Are There Environmental Concerns Associated with Cobalt Use?

Yes, there are significant environmental and ethical concerns associated with cobalt mining and processing. Cobalt is often mined in regions with lax environmental regulations, and the extraction process can lead to soil contamination, water pollution, and deforestation. Furthermore, there have been reports of child labor and human rights abuses in some cobalt mining operations.

Efforts to address these concerns include:

- Sustainable Mining Practices: Promoting responsible mining practices that minimize environmental impact and protect human rights.

- Recycling: Developing efficient recycling processes to recover cobalt from end-of-life products.

- Material Substitution: Exploring alternative materials that can reduce or eliminate the need for cobalt.

What Does the Future Hold for Cobalt-Based Magnetic Materials?

The future of cobalt-based magnetic materials looks promising, with ongoing R&D efforts focused on enhancing their magnetic performance, reducing costs, and improving sustainability. These materials will continue to play a crucial role in driving technological advancements across various industries.

Key areas of future development:

- Ultra-High-Density Recording: Enabling even greater data storage capacity in HDDs and other recording media.

- Next-Generation Electric Motors: Improving the efficiency and performance of electric vehicles and industrial machinery.

- Advanced Spintronics Devices: Developing new spintronic devices for faster and more energy-efficient computing.

- Sustainable Magnet Technologies: Creating magnets that are environmentally friendly and ethically sourced.

FAQ Section: Common Questions About Cobalt-Based Magnetic Materials

What is the difference between hard and soft magnetic materials?

Hard magnetic materials, like SmCo magnets, have high coercivity and retain their magnetization even in strong opposing fields. They are used for permanent magnets. Soft magnetic materials, like CoFe alloys, have low coercivity and are easily magnetized and demagnetized. They are used in transformers and inductors.

Why are cobalt magnets more expensive than ferrite magnets?

Cobalt magnets are more expensive due to the higher cost of cobalt and rare earth elements, as well as the complex manufacturing processes involved in producing high-performance magnets. Ferrite magnets, on the other hand, are made from inexpensive iron oxide materials.

Can cobalt-based magnets be recycled?

Yes, cobalt-based magnets can be recycled, and efforts are underway to develop more efficient recycling processes. Recycling helps to reduce the environmental impact of mining and reduces reliance on these elements.

Are there any regulations regarding the use of cobalt in magnetic materials?

There are no specific regulations targeting cobalt use solely in magnets. However, regulations related to hazardous materials used in manufacturing and those concerning conflict minerals may affect the usage of cobalt alongside certain rare earths.

How does temperature affect the performance of different cobalt alloys?

Different cobalt alloys have varying temperature stabilities. Alloys like SmCo exhibit high Curie temperatures and robust magnetic performance even at hundreds of degrees Celsius. The particular alloy composition can be tailored for a specified range of temperatures with specific magnetic qualities in mind.

Where can I learn more about the latest research on cobalt-based magnets?

Academic journals, scientific conferences, and industry publications are valuable resources for staying updated on the latest research advancements. Attending conferences, like Intermag, can provide valuable insights into cutting-edge developments.

Conclusion: Key Takeaways on Cobalt-Based Magnetic Materials

Here’s a summary of what we’ve covered in this article:

- Cobalt-based magnetic materials offer unique properties, including high Curie temperature and magnetocrystalline anisotropy.

- They are classified into various groups, including CoFe, CoPt, and Co-REM alloys, each with specific properties and applications.

- High Curie temperature is crucial for maintaining stable magnetic performance at elevated temperatures.

- Cobalt magnets are used in magnetic recording media, permanent magnets, Spintronics, electric motors, generators, and many other applications.

- Manufacturing challenges include the high cost of raw materials, complex alloy composition, and stringent processing requirements.

- Emerging trends focus on nanostructured materials, cobalt-free magnets, additive manufacturing, and computational materials design.

- Environmental concerns related to cobalt mining and processing need to be addressed through sustainable practices and recycling.

- The future holds exciting possibilities for cobalt-based magnetic materials, including ultra-high-density recording, next-generation electric motors, and advanced spintronics devices.

Cobalt remains extremely relevant in magnetism, and is one of the materials leading new technology and science breakthroughs.