Magnetism, magnets, and even common materials like steel play a vital role in countless applications we encounter daily. From the mundane to the magnificent, the interaction between these elements shapes our technologies and even how we understand the world. In this article, I want to take you on a journey to explore the fascinating world of magnets, delve into why steel is often attracted to them, and uncover the diverse applications that harness the power of magnetism. Prepare to discover the science behind the attraction and the ingenious ways we utilize it.

Why is Steel Often Attracted to Magnets?

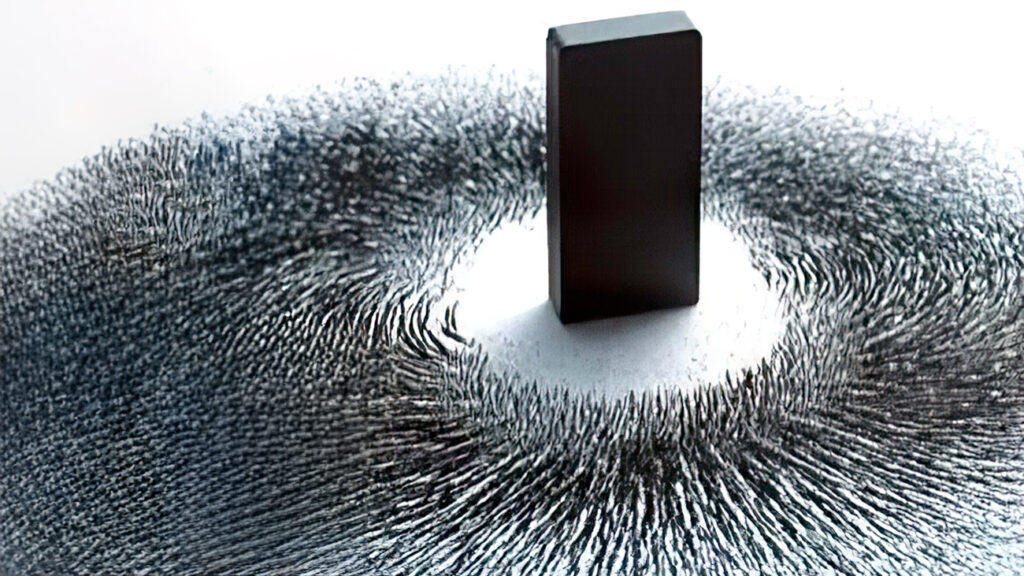

Steel, an alloy primarily composed of iron, exhibits a remarkable affinity for magnets. But why? The key lies in the microscopic structure of the iron atoms within the steel. Iron is what we call a ferromagnetic material. This means the atoms themselves act like tiny magnets. In a non-magnetized piece of iron, these individual "atomic magnets" point in random directions, effectively cancelling each other out.

When a magnet is brought near steel, the magnetic field from the magnet aligns these atomic magnets within the steel. This alignment creates a net magnetic field in the steel, making it attracted to the original magnet. The strength of the attraction depends on several factors, including the type of steel, the strength of the magnet, and the distance between them. Some steels, like stainless steel (depending on the precise composition), are engineered to be less ferromagnetic, reducing their attraction to magnets.

Here’s a table comparing different types of steel and their magnetic properties:

| Steel Type | Iron Content (Approximate) | Magnetische Eigenschaften | Gemeinsame Anwendungen |

|---|---|---|---|

| Kohlenstoffstahl | >98% | Highly Ferromagnetic | Construction, tools, automotive parts |

| Mild Steel | >98% | Highly Ferromagnetic | General purpose fabrication, pipelines |

| High-Speed Steel | Similar to Carbon Steel | Ferromagnetisch | Cutting tools, drill bits |

| Stainless Steel (304) | Vielfältig | Generally Austentitic (Weakly Magnetic or Non-Magnetic) | Kitchen appliances, surgical instruments |

| Stainless Steel (430) | Vielfältig | Ferritic (Magnetic) | Decorative trim, sinks |

How Strong is the Magnetism in Different Types of Magnets?

The strength of a magnet is determined by its magnetic field strength, usually measured in units called Tesla (T) or Gauss (G) (1 Tesla = 10,000 Gauss). Different types of magnets exhibit varying degrees of magnetic strength, largely depending on the materials used in their construction. For example, ceramic magnets, often found in speakers and small motors, are relatively weak, typically around 0.1-0.3 Tesla. Compare this to rare-earth magnets, such as neodymium magnets, which are exceptionally strong, reaching field strengths of up to 1.4 Tesla or even higher.

Alnico magnets, an alloy of aluminum, nickel, and cobalt, fall somewhere in between. Electromagnets, on the other hand, can achieve even higher field strengths, but only when actively powered by an electric current. The strength of an electromagnet is directly proportional to the current flowing through its coil. The core material of the electromagnet also plays a critical role. Using a ferromagnetic core, like iron or steel, will boost the magnetic field significantly.

Here’s a bulleted list illustrating the relative strength of different magnet types:

- Neodym-Magnete (Seltene Erde): Extremely Strong (up to 1.4+ Tesla)

- Samarium Cobalt Magnets (Rare Earth): Very Strong (around 0.8-1.1 Tesla)

- Alnico-Magnete: Moderate (around 0.15-1 Tesla)

- Ceramic (Ferrite) Magnets: Weak (around 0.1-0.3 Tesla)

- Electromagnets: Variable, dependent on current and core material (potentially >10 Tesla)

What are Some Everyday Applications of Magnets and Steel Working Together?

The combined properties of magnets and steel are exploited in countless everyday applications. Electric motors, the workhorses of modern technology, rely on the interaction between magnets and coils of wire (often wound around steel cores) to convert electrical energy into mechanical energy. From fans and washing machines to electric cars and power tools, electric motors are ubiquitous.

Speakers use magnets to generate sound waves. A coil of wire attached to a cone vibrates within a magnetic field created by a permanent magnet, producing sound based on the electrical signal fed into the coil. Magnetic hard drives store data by magnetizing tiny regions on a spinning disk made of a ferromagnetic material. The orientation of these magnetized regions represents the binary code (0s and 1s) that constitutes digital information.

Consider this scenario: You’re using a blender (powered by an electric motor) to make a smoothie, listening to your favorite music on a speaker, and the recipe you’re following is stored on your computer’s hard drive – all relying on the fundamental principles of magnetism and the interplay between magnets and steel!

How are Powerful Magnets Used in Medical Applications?

The medical field has greatly benefited from the development of powerful magnets. Magnetic Resonance Imaging (MRI) is a prime example, using strong magnetic fields (often generated by superconducting magnets) to create detailed images of the human body. These images allow doctors to diagnose a wide range of conditions, from brain tumors to torn ligaments.

Another application is targeted drug delivery. By attaching drugs to magnetic nanoparticles, doctors can guide these particles to specific locations in the body using external magnets, minimizing side effects and maximizing the drug’s effectiveness. Furthermore, magnets are used in some surgical procedures to manipulate instruments or tissues, enabling minimally invasive techniques. For example, small magnets can be used to guide a capsule endoscope through the digestive tract, providing a non-invasive alternative to traditional endoscopy.

Here’s a diagram illustrating how MRI works:

Grafik LR

A[Patient in MRI Machine] --> B(Strong Magnetic Field);

B --> C{Hydrogen Atoms Align};

C --> D(Radio Frequency Pulses);

D --> E{Atoms Emit Signals};

E --> F(Computer Processes Signals);

F --> G[Detailed Image of the Body];Can Magnets Be Used to Separate Steel from Waste?

Yes, magnetic separation is a widely used technique for separating steel and other ferromagnetic materials from waste streams. This process is essential for recycling efforts, allowing us to recover valuable steel from scrap metal, construction debris, and municipal solid waste. Large-scale magnetic separators often employ powerful electromagnets or permanent magnets mounted on rotating drums or conveyor belts.

As the waste material passes over the separator, the steel is attracted to the magnet and separated from the non-magnetic materials. This recovered steel can then be recycled and reused in new products, reducing the need for virgin materials and minimizing environmental impact. Magnetic separation is also used in mining operations to extract iron ore from other minerals.

In a large-scale municipal waste recycling plant, powerful electromagnets hanging over conveyor belts continuously attract and remove steel cans and other ferromagnetic debris, contributing to a cleaner and more sustainable environment.

How do Electromagnets Differ From Permanent Magnets?

Electromagnets and permanent magnets both generate magnetic fields, but they differ significantly in how those fields are produced and controlled. Permanent magnets, like neodymium or ferrite magnets, have a persistent magnetic field that is inherent to the material’s atomic structure. This field remains constant unless subjected to extreme temperatures or strong opposing magnetic fields.

Electromagnets, on the other hand, generate a magnetic field only when an electric current flows through a coil of wire. The strength of the magnetic field is directly proportional to the current flowing through the coil and the number of turns in the coil. Electromagnets offer the advantage of being able to be switched on and off, and their strength can be easily adjusted by varying the current. They are commonly used in applications where controlled and variable magnetic fields are required, such as in lifting magnets, electric motors, and scientific instruments.

Using a steel core within an electromagnet dramatically intensifies its magnetic field, as the steel becomes magnetized by the coil’s field.

Hier ist eine Vergleichstabelle:

| Merkmal | Permanent Magnet | Elektromagnet |

|---|---|---|

| Magnetisches Feld | Constant, always on | Only present when current flows |

| Feldstärke | Fixed by material properties | Variable, controlled by current |

| On/Off Control | Nein | Ja |

| Power Source | Keine | Electric current |

| Common Materials | Neodymium, Ferrite, Alnico | Copper wire, steel core |

What Role Does Magnetism Play in Electric Vehicles?

Magnetism is absolutely crucial to the operation of electric vehicles (EVs). Electric motors, which rely heavily on magnets, are the heart of an EV’s propulsion system. These motors convert electrical energy from the battery into mechanical energy to drive the wheels. High-performance EVs often use permanent magnet synchronous motors (PMSM) which utilize powerful rare-earth magnets, like neodymium magnets, to achieve high efficiency and power density.

Magnets are also used in the regenerative braking system of EVs. When the driver applies the brakes, the electric motor acts as a generator, converting the kinetic energy of the vehicle back into electrical energy, which is then stored in the battery. This regenerative braking system increases the overall efficiency of the EV and extends its driving range.

Moreover, the charging infrastructure for EVs relies on magnetic induction for wireless charging. A charging pad generates a magnetic field that induces a current in a receiver coil on the vehicle, effectively transferring energy wirelessly.

How Can You Demagnetize Steel?

While steel can be magnetized, it can also be demagnetized. Demagnetization essentially involves disrupting the alignment of the atomic magnets within the steel. Several methods can be used to achieve this, including:

- Heating: Heating the steel to a high temperature (above its Curie temperature) will randomize the orientation of the atomic magnets, effectively demagnetizing it.

- Applying an Alternating Magnetic Field: Subjecting the steel to a decreasing alternating magnetic field will gradually randomize the alignment of the atomic magnets. This is often done using a demagnetizer device.

- Impact or Vibration: Severe impact or vibration can also dislodge the atomic magnets from their aligned positions, reducing the overall magnetization.

However, not all demagnetization methods are equal. Heating can alter a steel’s temper, and repeated impacts can weaken its structural integrity.

Are There Steels That Aren’t Attracted to Magnets?

Yes, absolutely. While many types of steel are ferromagnetic and readily attracted to magnets, some steels are specifically designed to be non-magnetic or only weakly magnetic. These are primarily austenitic stainless steels. The austenitic structure is achieved by adding elements like nickel, manganese, and nitrogen to the steel alloy. This alters the crystalline structure of the steel in a way that prevents the alignment of the atomic magnets, resulting in a significantly reduced magnetic attraction.

For example, 304 stainless steel, a common grade used in kitchen appliances and food processing equipment, is typically non-magnetic in its annealed condition. However, cold working or welding can introduce some magnetism. Steel alloys are manipulated for very specific outcomes, including magnetism (or lack thereof).

What are the Future Trends in Magnet and Steel Applications?

The future of magnets and steel applications is bright, with ongoing research and development pushing the boundaries of what is possible. One exciting trend is the development of stronger and more efficient permanent magnets, particularly those that reduce reliance on rare-earth elements, which can be environmentally problematic to mine.

Advancements in materials science are also leading to the creation of new types of steel with enhanced magnetic properties, improved corrosion resistance, and higher strength-to-weight ratios. These new materials will enable the development of more efficient electric motors, lighter vehicles, and more durable structures.

Furthermore, the increasing demand for renewable energy is driving innovation in magnetic materials for wind turbines and other energy generation technologies. We can expect to see even more clever uses combining the properties of magnetism and steel emerge in the years to come.

FAQ-Abschnitt

Are all stainless steel alloys magnetic?

No, not all stainless steel alloys are magnetic. Austenitic stainless steels, like 304 stainless steel, are typically non-magnetic due to their crystalline structure, which is stabilized by the addition of elements like nickel and manganese. However, some martensitic and ferritic stainless steels are magnetic.

How does temperature affect the strength of a magnet?

Temperature can affect the strength of a magnet. As the temperature increases, the kinetic energy of the atoms within the magnet also increases, making it more difficult to maintain the alignment of the atomic magnets. At a certain temperature, known as the Curie temperature, the magnet will lose its magnetism completely.

Can a strong magnet erase data on a computer hard drive?

While a sufficiently strong magnet kann potentially disrupt the data on a traditional magnetic hard drive, it is not as easy as commonly portrayed in movies. Modern hard drives are shielded, and the magnetic fields required to reliably erase data are significantly stronger than those produced by most household magnets. Solid-state drives (SSDs), which do not use magnetic storage, are unaffected by magnets.

What is the difference between a north pole and a south pole on a magnet?

A magnet has two poles, a north pole and a south pole. These poles arise from the alignment of the tiny atomic magnets within the material. Magnetic field lines emerge from the north pole and enter the south pole, creating a closed loop. Opposite poles attract each other, while like poles repel each other.

Are there any health risks associated with being around strong magnets?

While strong magnetic fields can interact with metallic implants in the body (such as pacemakers or certain surgical implants), there is generally no evidence to suggest that exposure to static magnetic fields poses a direct health risk to most people. However, it is advisable to avoid prolonged exposure to extremely strong magnetic fields. MRI machines are routinely used and considered safe under proper protocols.

How can I test if a material is steel?

The easiest way to test if a material is steel (or at least has a significant iron content) is to use a magnet. If the magnet is strongly attracted to the material, there’s a strong possibility it is a steel alloy. However, it is best used as a starting point, as some stainless steels are non-magnetic. More definitive methods like spark testing and chemical analysis are best practice.

Schlussfolgerung: Die wichtigsten Erkenntnisse

- Steel’s attraction to magnets arises from the alignment of atomic magnets within its iron content.

- Different magnet types exhibit varying degrees of strength, with rare-earth magnets being the strongest.

- Magnets and steel are crucial components in electric motors, speakers, and data storage devices.

- Powerful magnets play an essential role in medical applications like MRI and targeted drug delivery.

- Magnetic separation is a widely used technique for recycling steel from waste streams.

- Electromagnets offer the advantage of controllable magnetic fields, while permanent magnets provide persistent fields.

- Some stainless steel alloys are designed to be non-magnetic for specialized applications.

- Ongoing research and development are driving advancements in magnetic materials for a wide range of applications.