Holey magnets, also known as magnets with holes, are more than just curious novelties. They offer unique magnetic properties and applications that are revolutionizing various industries. This article dives deep into the fascinating world of holey magnets, exploring their characteristics, manufacturing processes, and diverse uses. Prepare to discover how these seemingly simple modifications can unlock tremendous potential!

1. What Makes Holey Magnets Different? Exploring Enhanced Magnetic Fields

The presence of a hole within a magnet dramatically alters its magnetic field. But how do these modifications impact the overall magnetic performance?

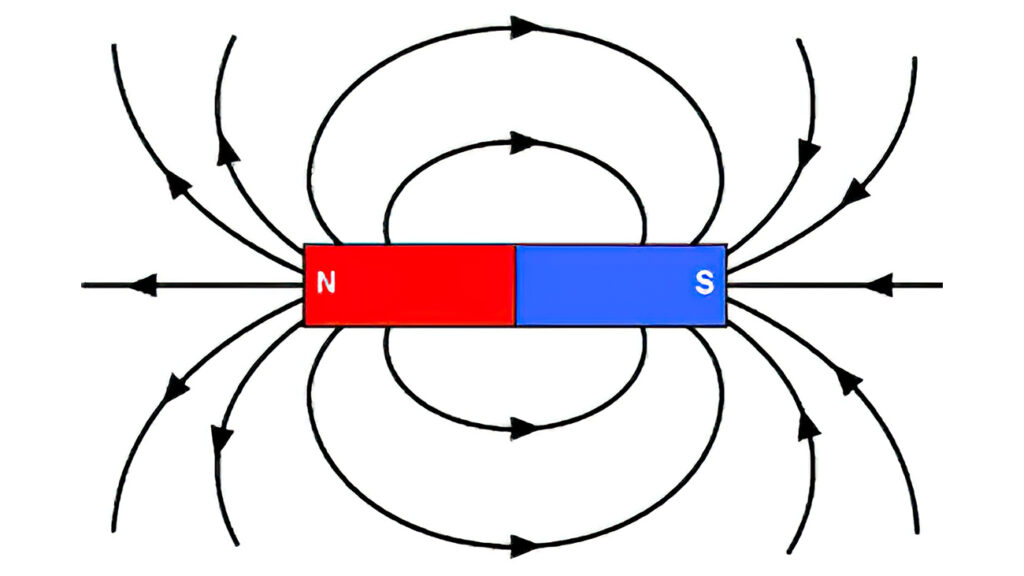

Firstly, drilling a hole disrupts the magnetic flux lines within the magnet. Instead of flowing seamlessly through the material, these lines are forced to curve or redirect. This results in a more concentrated magnetic field around the hole.

Secondly, the removal of material reduces the overall mass of the magnet, potentially impacting its strength depending on the size and placement of the hole. However, strategic design can actually increase the field strength in specific areas.

Imagine a donut-shaped magnet compared to a solid cylindrical magnet of the same material and volume. The donut magnet, due to its central hole, will have a different magnetic field distribution. The field lines tend to concentrate at the inner and outer circumferences of the donut, leading to localized enhancements.

2. How Are Holey Magnets Manufactured? Precision and Techniques

Creating a hole in a magnet isn’t as simple as grabbing a drill. The process requires careful consideration of the magnet’s material and desired characteristics. What methods ensure precision and minimize damage?

Several methods exist, each with its own advantages and drawbacks:

- Pulvermetallurgie: This is the most common technique. The hole is created during the sintering process by incorporating a mandrel (a core material that won’t sinter and is later removed) into the mold. This provides precise control over the hole’s size and shape.

- Machining: For existing magnets, machining techniques like electrical discharge machining (EDM) or laser cutting are often employed. EDM uses electrical discharges to erode the material, while laser cutting uses a focused beam of light to vaporize it. These methods are suitable for complex hole geometries.

- Ultrasonic Machining (USM): Uses abrasive slurry and high-frequency vibrations to gradually wear away the magnet material. Excellent for hard and brittle materials, minimizing stress.

The choice of method depends on factors such as the magnet material (neodymium magnets are notoriously brittle), required tolerance, and the complexity of the hole geometry. Special care must be taken to prevent demagnetization during the manufacturing process.

3. Fine-Tuning Magnetic Properties: Understanding the Impact of Hole Size and Placement

The location and size of the hole play a crucial role in defining the unique magnetic characteristics of holey magnets. How can these parameters be optimized?

Generally speaking, a larger hole will result in a greater disruption of the magnetic field, leading to a more pronounced concentration around the hole’s edges. The placement is equally important. A centrally located hole will create a symmetrical field distribution, whereas an off-center hole will result in an asymmetrical field.

For example, placing a hole close to one pole of the magnet can significantly enhance the magnetic field on the opposite pole. This is leveraged in some sensor applications.

I recall working on a project where we needed to precisely control the magnetic field strength at a specific distance from the magnet. After experimenting with different hole sizes and placements using simulations and prototypes, we were able to achieve the desired field profile. We found that a slightly off-center hole, combined with a carefully chosen diameter, provided the optimal solution. This highlights how precise control over these parameters can unlock specific performance characteristics.

4. What Applications Benefit Most from Holey Magnets? A Wide Range of Uses

Holey magnets find application in a variety of industries due to their unique properties. In what sectors are they particularly beneficial?

- Sensoren: Holey magnets are excellent for creating accurate position and speed sensors. The change in magnetic field as a target passes near the hole can be precisely measured.

- Magnetische Kupplungen: By carefully designing the hole geometry, one can create magnetic couplings with specific torque characteristics. Think of a magnetic gear without physical contact.

- Medizinische Geräte: Tiny holey magnets are used in targeted drug delivery systems, guiding magnetic nanoparticles to specific areas within the body.

- Research: Scientists use holey magnets to create complex magnetic field configurations for studying magnetic materials and phenomena.

- Elektrische Motoren: Holey magnets reduce weight in motors, which improves their energy efficiency, and can lead to improved torque characteristics.

- Elektronik: Certain designs enable improvements to existing inductive components and filters.

This versatility makes holey magnets a key component in numerous innovative technologies.

5. Magnetic Shielding with Holey Magnets: Is it Possible?

Magnetic shielding is essential in many electronic devices to prevent interference. Can holey magnets contribute to effective shielding solutions?

While a standard solid magnet will attract other magnetic materials, a cleverly designed holey magnet can be used for very localized magnetic shielding – but not in the traditional, comprehensive sense. The concentrated flux lines around the hole can effectively capture and contain magnetic fields within a small region.

However, it’s important to note that holey magnets are not typically used as primary magnetic shields. Traditional shielding materials like Mu-metal are far more effective at attenuating magnetic fields over larger areas. The application is generally for very small, specialized setups.

6. Advantages of Holey Magnets Over Solid Magnets: A Comparative Analysis

In what specific scenarios do holey magnets offer distinct advantages over their solid counterparts?

Here’s a comparison table highlighting the benefits:

| Merkmal | Holey Magnet | Solider Magnet |

|---|---|---|

| Field Concentration | Enhanced around the hole | Evenly distributed |

| Gewicht | Lower (due to material removal) | Höher |

| Sensor Applications | Excellent for precise sensing | Less sensitive to small changes |

| Magnetische Kupplungen | Fine control over torque curves | Limited flexibility |

| Material Usage | Reduced material | Full material usage |

In summary, holey magnets excel in applications where localized field enhancements, weight reduction, and precise sensing are crucial.

7. Cost Considerations: Are Holey Magnets More Expensive?

Does the manufacturing process and added complexity of holey magnets translate to higher costs?

Generally, yes. Manufacturing holey magnets is more complex than producing solid magnets. The additional steps involved in drilling, machining, or incorporating a mandrel during sintering contribute to increased production costs.

Furthermore, the more intricate the hole geometry and tighter the tolerances, the higher the price.

However, the added cost can be justified in applications where the unique benefits of holey magnets provide a significant performance advantage or enable new functionalities. The key is to weigh the cost against the potential benefits in each specific application.

8. Future Trends in Holey Magnets: What’s on the Horizon?

What innovations and advancements can we expect to see in the field of holey magnets in the coming years?

- Fortgeschrittene Materialien: Research into new magnetic materials with enhanced properties will further boost the performance of holey magnets.

- 3D-Druck: Additive manufacturing techniques could revolutionize the fabrication of complex holey magnet geometries, enabling custom designs with unprecedented precision.

- Micro-Holey Magnets: The miniaturization of holey magnets will open up new possibilities in medical devices, micro-robotics, and other micro-scale applications.

- Intelligente Magnete: Integrating sensors and electronic components directly into holey magnets will create "smart magnets" with advanced control and feedback capabilities.

These trends point towards a bright future for holey magnets, with continued innovation driving new applications and pushing the boundaries of magnetic technology.

9. Can I Make My Own Holey Magnet? DIY Considerations

Could I, in theory, drill a hole into an existing magnet and create my own holey magnet? What would prevent me from succeeding?

While technically possible, drilling into an existing magnet is a risky endeavor, especially with brittle materials like neodymium.

Here are the challenges:

- Entmagnetisierung: The heat and vibration generated during drilling can cause a significant loss of magnetization. Keeping the magnet cold during drilling is crucial.

- Cracking and Chipping: Brittle magnets are prone to cracking and chipping, especially near the edges of the hole.

- Tooling: Specialized tools like diamond drill bits are required to minimize damage.

If you’re determined to try it, use a slow drilling speed, plenty of coolant, and a drill press to maintain stability. Start with a spare magnet and expect some experimentation. However, for critical applications, it’s always best to purchase professionally manufactured holey magnets.

10. Real-World Examples: Showcasing the Applications of Holey Magnets

Let’s bring this all together by seeing how holey magnets impact real-world applications.

Case Study 1: High-Performance Electric Motor

A leading electric motor manufacturer introduced a new motor design employing holey magnets in the rotor. The result was a 15% reduction in motor weight and a 10% increase in torque. The holey magnets improved efficiency leading to a lower weight.

Case Study 2: Precision Sensor

An automotive sensor company incorporated holey magnets into their wheel speed sensors. The use of holey magnets increased the sensor’s accuracy and improved its performance making them much more efficient overall.

These case studies demonstrate the tangible benefits of using holey magnets in real-world applications, showcasing their potential to improve performance, reduce costs, and enable new functionalities.

FAQ-Abschnitt

Question: Are all magnets with holes considered "holey magnets" for specialized applications?

No. The term "holey magnet" typically refers to magnets where the hole is intentionally designed and manufactured to alter the magnetic field in a specific way. Simply drilling a hole in a magnet for mounting purposes doesn’t automatically make it a holey magnet in this context.

Question: What types of magnetic materials are commonly used for holey magnets?

Neodymium magnets (NdFeB) are the most common choice due to their high magnetic strength. However, other materials like samarium cobalt (SmCo) and ferrite magnets can also be used, depending on the specific application requirements.

Question: Can the holes in holey magnets be any shape and size?

Yes, theoretically. However, the shape and size of the hole significantly impact the magnetic field distribution. Circular holes are common, but other shapes like square, rectangular, and even more complex geometries can be used to achieve specific field characteristics. Complex holes increase the manufacturing cost.

Question: How do I choose the right holey magnet for my specific application?

Consider the required magnetic field strength, desired field distribution, operating temperature, size constraints, and cost considerations. Consulting with a magnet manufacturer or using simulation software can help you optimize your design.

Question: Are there any safety precautions to consider when working with holey magnets?

Yes. Like all strong magnets, holey magnets can attract to each other or to ferrous materials with considerable force, posing a pinching hazard. Keep magnets away from sensitive electronic devices and pacemakers. Follow the same safety guidelines as you would for any other powerful magnet.

Conclusion: Key Takeaways about Holey Magnets

- Holey magnets offer unique magnetic properties due to the disrupted magnetic flux lines around the hole.

- Manufacturing methods include powder metallurgy, machining, and ultrasonic machining, and the optimal method depends on the magnet material and required precision.

- The size and placement of the hole significantly impact the magnetic field distribution.

- Holey magnets find applications in sensors, magnetic couplings, medical devices, and electric motors.

- While not primary magnetic shields, they can be used for localized field containment.

- Holey magnets often offer advantages over solid magnets when localized field enhancement and weight reduction are prioritized.

- Future trends include advanced materials, 3D printing, and micro-holey magnets.

Understanding the power of holey magnets opens up a world of possibilities for innovative designs and advanced technologies. As research and development continue, we can expect to see even more exciting applications emerge in the years to come.