Powerful magnets are more than just fridge decorations; they’re essential components in countless technologies, from the motors that power our cars to the hard drives that store our data. This article will delve into the fascinating world of powerful magnets, exploring their different types, applications, and the science behind their incredible strength. We’ll uncover the mysteries of neodymium magnets, examine the roles of alnico and ferrite magnets, and investigate how these remarkable materials are shaping our future. Consider this your comprehensive guide to understanding the awesome power of magnets!

What Makes Powerful Magnets So… Powerful? Understanding Magnetic Materials

Magnets aren’t all created equal. Some barely stick to a refrigerator, while others can lift hundreds of pounds. The secret lies in the material’s composition and its ability to maintain its magnetic properties. The power of a magnet depends heavily on the alignment of its atomic magnetic moments. Essentially, when the tiny "magnets" within each atom all point in the same direction, the material becomes magnetized. The stronger the alignment and the more atoms that are aligned, the more powerful the magnet becomes.

Atomic Structure and Alignment: Materials like iron, nickel, and cobalt have electron configurations that make them easily magnetized.

Domain Formation: Within a magnetic material, small regions called domains align their magnetic moments.

- Magnetization Process: Applying a strong external magnetic field can align these domains, creating a permanent magnet.

Neodymium Magnets: Are They the Strongest Magnets on Earth?

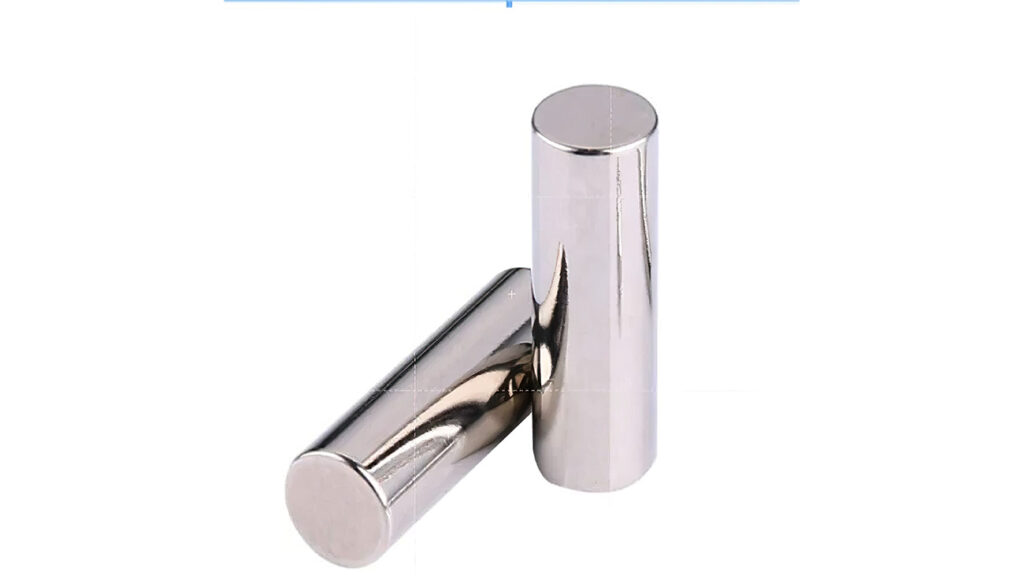

Neodymium magnets, also known as NdFeB magnets (neodymium iron boron), are indeed among the strongest permanent magnets commercially available. They boast exceptional magnetic strength due to their unique composition and manufacturing process. Their discovery and subsequent widespread use have revolutionized many industries, allowing for smaller, more efficient devices.

These magnets are created by sintering (heating without melting) a finely powdered mixture of neodymium, iron, and boron. This process aligns the magnetic domains within the material, resulting in a magnet with incredibly high energy product – a measure of its magnetic strength.

Neodymium Magnet Facts:

- High Energy Product: NdFeB magnets have the highest energy product of any commercially available magnet.

- Susceptible to Corrosion: They are prone to corrosion and are often coated with nickel, zinc, or epoxy to protect them.

- Temperatur-Empfindlichkeit: Their magnetic strength decreases at higher temperatures.

Alnico Magnets: How Do They Compare in Magnetic Force?

Alnico magnets, composed primarily of aluminum, nickel, and cobalt (hence the name), offer a different set of characteristics compared to neodymium magnets. While they aren’t as powerful as neodymium magnets, they possess some significant advantages, particularly in high-temperature applications.

Alnico magnets are manufactured using two main methods: casting and sintering. Cast alnico magnets can be made in complex shapes, while sintered alnico magnets offer better mechanical strength. The high Curie temperature of alnico magnets (the temperature at which they lose their magnetization) allows them to operate effectively in temperatures that would demagnetize neodymium magnets.

| Magnet Typ | Stärken | Schwachstellen |

|---|---|---|

| Neodym | Extremely strong, small size | Prone to corrosion, temperature sensitive |

| Alnico | Good high-temperature performance, relatively stable | Less powerful than neodymium, more brittle |

Ferrite Magnets: Are They a Cost-Effective Magnetic Solution?

Ferrite magnets, also known as ceramic magnets, are composed of iron oxide combined with strontium or barium carbonate. They are the most widely produced magnets due to their low cost and good resistance to corrosion. While significantly weaker than neodymium magnets and alnico magnets, their cost-effectiveness makes them ideal for a wide range of applications, particularly in loudspeakers, electric motors, and magnetic separators.

Ferrite magnets are generally manufactured via a powder metallurgy process. The raw materials are mixed, calcined (heated), milled into a fine powder, and then pressed into shape under high pressure. Finally, the pressed part is sintered at high temperature to fuse the particles together.

Key features of Ferrite magnets:

- Inexpensive: The raw materials are readily available and relatively cheap.

- Corrosion Resistant: Ferrite magnets are highly resistant to corrosion, making them suitable for use in harsh environments.

- Geringere magnetische Stärke: They have a lower energy product compared to neodymium and alnico magnets.

What Diverse Applications Are Powerful Magnets Used In?

Powerful magnets are found in countless applications, spanning various industries and technological fields. From renewable energy to medical devices, their unique properties drive innovation and efficiency.

Elektromotoren und Generatoren: Powerful magnets, particularly neodymium magnets, are essential for creating efficient and compact electric motors and generators used in electric vehicles, wind turbines, and industrial machinery.

Magnetresonanztomographie (MRI): MRI machines rely on strong magnetic fields generated by superconducting magnets to produce detailed images of the human body.

Hard Disk Drives (HDDs): Powerful magnets are used in the read/write heads of hard disk drives to store and retrieve data.

Lautsprechern: Ferrite magnets or neodymium magnets are often found in loudspeakers, used to convert electrical signals into sound waves.

Magnetische Abscheider: Magnets are used to separate ferrous materials from non-ferrous materials in recycling plants and mining operations.

- Medical field: Guiding medical devices, like capsules, through the digestive system.

Can Powerful Magnets Be Dangerous? Understanding Safety Precautions

Despite their usefulness, powerful magnets can pose certain dangers if not handled correctly. The strong attractive forces they generate can cause serious injuries or damage to electronic devices. It is vital to take precautions when working with magnets to avoid potential harm.

Quetschpunkte: The powerful attraction between magnets can easily pinch fingers or other body parts, leading to painful injuries. Always handle magnets with care and keep fingers clear of the joining surfaces.

Elektronische Geräte: Powerful magnets can damage or erase data on electronic devices such as credit cards, hard drives, and pacemakers. Keep magnets away from sensitive electronics.

Swallowing Hazards: Small magnets, especially those removed from toys, can be swallowed by children, causing serious internal injuries. Keep magnets out of reach of children.

- Shattering: Neodymium magnets, in particular, are brittle and can shatter upon impact, creating sharp fragments that can cause eye injuries. Wear safety glasses when handling them.

How Is the Strength of a Magnet Measured: Gauss vs. Tesla?

The strength of a magnet is typically measured using two units: Gauss (G) and Tesla (T). These units quantify the magnetic flux density, which represents the amount of magnetic field passing through a given area. Understanding the difference between Gauss and Tesla, and which unit is most suitable for describing the magnetic strength of a magnet.

Gauss (G): Gauss is the older unit of magnetic flux density. It is still commonly used, particularly in the United States.

Tesla (T): Tesla is the SI unit of magnetic flux density. One Tesla is equal to 10,000 Gauss (1 T = 10,000 G).

- Typical Values: The Earth’s magnetic field is about 0.5 Gauss, while a strong neodymium magnet can have a surface magnetic field of over 1 Tesla (10,000 Gauss).

The magnetic field strength is measured using a Gaussmeter or a Teslameter. These devices use a Hall effect sensor to measure the magnetic field strength at a specific point.

Demagnetization: What Are the Factors That Cause Magnets to Lose Strength?

Magnets don’t stay permanently "magnetic" forever. Over time, or under certain adverse conditions, magnets can lose their strength, a process called demagnetization. Understanding this process is crucial for choosing the right magnet for a specific application and ensuring its longevity.

Several factors can contribute to demagnetization:

Temperatur: Exposing a magnet to high temperatures can disrupt the alignment of its magnetic domains, leading to a loss of strength. The Curie temperature is the temperature at which a magnet completely loses its magnetization.

External Magnetic Fields: Applying a strong external magnetic field in the opposite direction to the magnet’s original magnetization can cause demagnetization.

Impact and Vibration: Severe impacts or vibrations can misalign the magnetic domains, resulting in reduced magnetic strength.

- Korrosion: Corrosion can damage the magnetic material, leading to a gradual loss of magnetic properties.

Are There Any Emerging Technologies that Utilize Powerful Magnets?

The advancements in magnet technology are paving the way for exciting new applications. Innovations in materials science and engineering are yielding even more powerful and efficient magnets, opening doors to emerging technologies that promise to transform various industries.

Maglev Trains: Magnetic levitation (Maglev) trains use powerful magnets to levitate above the tracks, reducing friction and enabling extremely high speeds.

Fusion Energy: Fusion reactors use powerful magnets to confine and control the plasma, a crucial step in harnessing fusion energy as a clean and sustainable energy source.

Advanced Robotics: Powerful, lightweight magnets are enabling the development of advanced robots with enhanced dexterity and precision.

- Biomedical Applications: Magnets are being explored for targeted drug delivery, magnetic hyperthermia for cancer treatment, and magnetic separation of biological cells.

What Does the Future Hold for Powerful Magnet Research and Development?

The field of magnet research and development is constantly evolving, driven by the demand for stronger, more efficient, and more sustainable magnetic materials. Scientists and engineers are exploring new materials, manufacturing techniques, and applications for powerful magnets that could shape the future of technology.

Areas of focus in magnet R&D:

Rare Earth Alternatives: Research into alternative materials that don’t require rare earth elements, addressing concerns about supply chain vulnerability and environmental impact.

Hochtemperatur-Magnete: Development of magnets that can withstand even higher temperatures, expanding their use in demanding applications such as electric vehicles and aerospace.

Additive Manufacturing: Exploring additive manufacturing (3D printing) techniques to create complex magnet shapes with optimized performance.

- Improved Corrosion Resistance: Developing coatings and materials with enhanced corrosion resistance to prolong the lifespan of magnets in harsh environments.

Frequently Asked Questions About Powerful Magnets

Let’s tackle some common questions about powerful magnets to ensure a comprehensive understanding.

What is the strongest type of permanent magnet currently available?

Neodymium magnets (NdFeB) are currently the strongest type of permanent magnet commercially available. They have the highest energy product, allowing them to generate incredibly strong magnetic fields for their size.

How should I store powerful magnets to prevent them from losing their strength?

Store magnets away from high temperatures, strong magnetic fields, and corrosive environments. Separate them to prevent them from snapping together and potentially chipping or breaking. Using a keeper (a piece of soft iron) can help preserve their magnetic strength over long periods.

Can powerful magnets damage my cell phone or computer?

Yes, powerful magnets can potentially damage electronic devices. Keep them away from cell phones, computers, credit cards, and other devices with magnetic storage or sensitive electronic components.

Are there any health risks associated with prolonged exposure to strong magnetic fields?

While typical exposure to magnetic fields from household appliances is generally considered safe, prolonged exposure to very strong magnetic fields, such as those used in MRI machines, can have potential health effects. It’s important to follow safety guidelines and consult with medical professionals if you have concerns.

How do I choose the right magnet for a specific application?

Choosing the right magnet depends on several factors, including the required magnetic strength, operating temperature, size constraints, and cost considerations. Consider the pros and cons of each magnet type (neodymium, alnico, ferrite) and consult with magnet experts if needed.

What is the Curie temperature of a magnet, and why is it important?

The Curie temperature is the temperature at which a magnet completely loses its magnetization. It is an important factor to consider when choosing a magnet for applications where it will be exposed to high temperatures. Exceeding the Curie temperature will permanently demagnetize the magnet.

Conclusion: Powerful Magnets – A Summary of Key Takeaways

Powerful magnets continue to shape our world in profound ways, driving innovation across industries and enabling countless technological advancements. Understanding their properties, applications, and safety precautions is essential for harnessing their full potential.

Hier ist eine Zusammenfassung der wichtigsten Erkenntnisse:

- Neodymium magnets are the strongest commercially available permanent magnets.

- Alnico magnets offer excellent high-temperature performance.

- Ferrite magnets are a cost-effective solution for a wide range of applications.

- Handle powerful magnets with care to avoid pinch injuries and damage to electronic devices.

- The strength of a magnet is measured in Gauss or Tesla.

- Magnets can lose their strength due to high temperature, external magnetic fields, and corrosion.

- Emerging technologies, such as maglev trains and fusion energy, rely heavily on powerful magnets.

By continuing to explore the science and applications of powerful magnets, we can unlock even greater possibilities for innovation and improvement in our future.