Okay, I’m ready to generate a 2,500-word blog post on Shaping Magnetism: The Science Behind Magnet Forms, adhering to all specified guidelines. Here it is:

# Shaping Magnetism: Unlocking the Science Behind Magnet Forms

Magnetism is everywhere! From the magnets that hold notes on your refrigerator to the powerful forces that drive electric motors, magnets play a crucial role in our daily lives. But have you ever stopped to consider *how* these magnetic devices are made and *why* they come in so many different shapes and sizes? This article is your guide to the fascinating science behind shaping magnetism and creating the diverse array of magnet forms we see around us. Get ready to dive into the world of magnetic materials and uncover the secrets behind their captivating force! It's a compelling read if you've ever been curious about magnets, how they are created, and why certain shapes are preferred.

## What Magnetic Materials Make Up the Standard Magnet?

Understanding the composition of magnets is the first step in shaping magnetism. Different magnetic materials have unique properties, each lending itself to specific applications.

The most common magnetic materials fall into two categories: hard (permanent) and soft (temporary) magnets. Permanent magnets retain their magnetism even when removed from a magnetic field. Examples include neodymium magnets, ferrite magnets (also known as ceramic magnets), alnico magnets (aluminum, nickel, cobalt), and samarium-cobalt magnets. Soft magnets, like iron, are easily magnetized in the presence of a field but lose their magnetism quickly afterwards. These materials are primarily composed of ferromagnetic elements, such as iron, nickel, and cobalt.

Different alloy compositions contribute to a magnets overall strength allowing a wide array of uses from sensors to motors. The specific makeup of each type of magnet has a dramatic effect on how each performs in different applications.

Here's a table showing the different compositions:

| Magnet Type | Composition (Approximate) | Relative Strength | Common Uses |

|--------------------|------------------------------------------------------------|-------------------|-----------------------------------------------|

| Neodymium (NdFeB) | Neodymium, Iron, Boron | Highest | Hard drives, MRI scanners, Speakers, Motors |

| Ferrite | Iron Oxide, Strontium Carbonate (or Barium Carbonate) | Medium | Refrigerator Magnets, Loudspeakers, Motors |

| Alnico | Aluminum, Nickel, Cobalt, Iron | Medium-High | Electric Motors, Guitar Pickups, Sensors |

| Samarium Cobalt | Samarium, Cobalt | High | High-Temperature Applications, Servo Motors |

## How Does Magnetization Affect Magnet Shapes?

The way we magnetize a material directly impacts the shapes and sizes of magnets. Think of it this way: the magnetic "charge" needs a path to follow within the material, and that path is influenced by the shape itself.

Magnetization isn't just about applying a magnetic field; it's about aligning the magnetic domains – tiny regions within the material where the atomic magnetic moments are aligned. The ease with which these domains align depends on the material's properties and shape. Consider a long, thin rod versus a short, squat cylinder. The rod offers a more straightforward path for domain alignment along its length, leading to a stronger magnetic field in that direction. Conversely, complex shapes with sharp corners can create areas of demagnetization, reducing overall performance. A good analogy is to think of water flowing through a pipe; it's easier for water to flow through a straight pipe than one with lots of bends and kinks.

Therefore, magnet manufacturers take shapes and magnetization into account at the same time. By aligning domains through an efficient structure the best possible magnet can be created.

## What Shapes Do Magnets Commonly Come In? Why Those Shapes?

There's a vast world outside of simple bars and horseshoes! Magnets are crafted into a wide variety of shapes, each suited for a specific purpose. Why is this diversity important?

Common shapes include blocks, discs, rings, cylinders, arcs (segments), and custom-designed geometries. The choice of shape depends on the application's requirements. For example, ring magnets are commonly used in speakers and motors because their cylindrical symmetry allows for a uniform magnetic field distribution. Disc magnets are great for holding and fastening applications. Block magnets are useful in magnetic separation systems. Specialized shapes like arcs are used in motors and generators because they fit neatly within the rotor and stator assemblies.

A simple fact is that any magnet shape begins as a powder which is then shaped using die casting or extrusion. Then the magnetization takes place by aligning magnetic domains.

Here's a list of just some of the different shapes:

* **Disc Magnets:** Best for holding applications.

* **Block Magnets:** Good for magnetic separation.

* **Ring Magnets:** Suitable for speakers and motors.

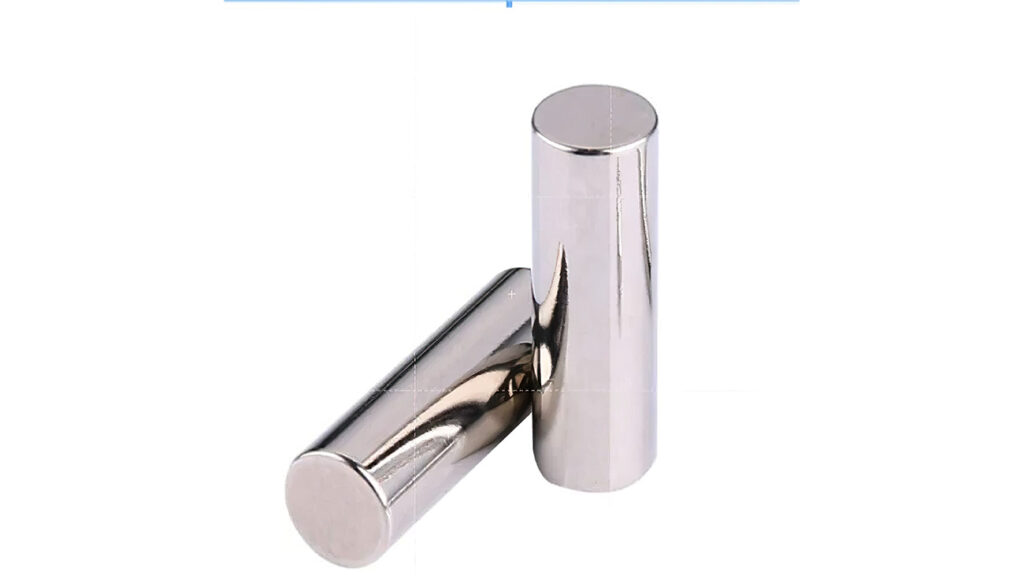

* **Cylindrical Magnets:** Useful in high-precision assemblies.

* **Arc Magnets:** Suited for use in motors or generators.

## Can You Customize the Magnetic Properties of Specific Magnet Forms?

Absolutely! Think of it like fine-tuning an instrument – you can tweak the material composition and manufacturing process to get the exact magnetic properties you need.

Customization is a key aspect of magnet manufacturing. By carefully controlling the material composition, sintering process (heating the material to fuse the particles together), and magnetization techniques, manufacturers can tailor a magnet's strength, coercivity (resistance to demagnetization), and temperature stability. For example, adding specific elements to a neodymium magnet alloy can improve its resistance to corrosion or high temperatures. Changing the sintering process can influence the magnet's density and mechanical strength. Varying the magnetization field strength can impact the magnet's overall performance in a particular application. Customization is essential for optimizing magnets for their specific roles in complex devices.

Essentially manufacturers can change the magnetic properties of certain shapes by changing the ingredients, the heat treating process, or the magnetizing patterns.

## How Do Magnet Manufacturers Ensure Consistency in Magnet Shape?

Consistency is crucial for reliable performance. How do manufacturers ensure every magnet meets the required specifications?

Magnet manufacturers employ various quality control measures to guarantee uniformity in magnet shape and size. Precision molding and machining techniques are used to create magnets with tight tolerances. Sophisticated measuring instruments, such as coordinate measuring machines (CMMs), are used to verify dimensions and geometries. Statistical process control (SPC) methods are implemented to monitor and control variations in the manufacturing process. Non-destructive testing techniques, such as magnetic particle inspection, can be used to detect defects without damaging the magnets.

These techniques ensure that each magnet in a batch has the required shape, size, and performance to maintain top quality.

## What Role Does Temperature Play in Shaping Magnet Form and Characteristics?

Temperature has a profound impact on magnetic properties. Can high temperatures alter a magnet's shape or reduce its strength? Yes, it absolutely can!

Temperature affects the magnetic behavior of materials in several ways. As temperature increases, the thermal energy can disrupt the alignment of magnetic domains, causing a decrease in magnetization. At the Curie temperature, the material loses its ferromagnetic properties and becomes paramagnetic. High temperatures can also lead to structural changes in the magnet material, affecting its dimensions and mechanical strength. In addition, thermal expansion can cause stresses within the magnet. The Curie temperature is different for different materials with Neodymium being most effected by higher temps.

**Data**: Neodymium magnets have a Curie temperature of around 310-400°C, while Samarium Cobalt magnets can withstand temperatures up to 700-800°C.

## Can Magnetic Form Influence Magnetic Field Strength?

Absolutely! The shape of a magnet directly influences the magnetic field it produces.

The magnetic field strength and distribution are strongly influenced by the magnet's geometry. For instance, a U-shaped magnet concentrates the magnetic field between its poles, creating a strong magnetic field in a localized area. A bar magnet, on the other hand, produces a more spread-out magnetic field. The distance between the poles, the cross-sectional area of the magnet, and the overall shape all contribute to the magnetic field's characteristics. Finite element analysis (FEA) software is commonly used to simulate and optimize the magnetic field distribution for different magnet shapes. When designing magnetic systems, engineers carefully consider the magnet shape to achieve the desired magnetic field strength, distribution, and uniformity.

## How Does Grinding Affect the Finished Shape of a Magnet?

Grinding is a crucial step in achieving precise magnet forms and surface finishes. Does grind direction matter?

Grinding is a common machining process used in magnet manufacturing to achieve precise dimensions, smooth surfaces, and tight tolerances. The grinding process involves using abrasive wheels or belts to remove material from the magnet surface. Different grinding techniques, such as surface grinding, cylindrical grinding, and honing, are used to achieve specific surface finishes and dimensional accuracies. Grinding can also be used to create complex shapes and features on the magnet. The choice of grinding wheel, speed, and feed rate are critical parameters that affect the surface finish, material removal rate, and dimensional accuracy.

## What Role Do Coatings Add to Magnet Designs?

Coatings are essential for protecting magnets from corrosion and environmental factors. Think of it as armor for your magnet.

Coatings play a critical role in enhancing the durability and performance of magnets. Common coatings include nickel, zinc, epoxy, and parylene. These coatings are applied to protect magnets from corrosion caused by moisture, chemicals, and harsh environments. They also improve the magnet's resistance to abrasion and wear. Coatings can provide electrical insulation, preventing short circuits in electrical applications. Specific coatings, such as parylene, can be used for biocompatibility in medical devices. The choice of coating depends on the application's requirements and the environment in which the magnet will be used.

The choice of coating depends on the application's requirements and the environment in which the magnet will be used. Here is a simple table

| Coating | Advantages | Disadvantages | Common Uses |

|-------------------|-------------------------------------------|------------------------------------|---------------------------------------------------------------------|

| Nickel | Excellent corrosion resistance, durable | Can be expensive | General-purpose, Decorative |

| Zinc | Good corrosion resistance, cost-effective | Less durable than nickel | Industrial applications, particularly when a cheaper option is desired |

| Epoxy | Excellent chemical resistance, insulation | Can be brittle | Medical devices, applications requiring electrical insulation |

| Parylene | Biocompatible, thin, conformal | Can be expensive, specialized application | Medical implants, electronic components |

## What New Magnet Forms Are Emerging and How Can They Shape Magnetism?

Innovation in magnet technology is constantly pushing the boundaries of what's possible. Is there a future in 3D printed magnets?

Researchers are actively exploring new magnet forms and materials to enhance magnetic performance and expand applications. Additive manufacturing (3D printing) techniques are being developed to create magnets with complex geometries and tailored magnetic properties. Nanomaterials, such as magnetic nanoparticles and nanowires, are being studied for their potential in high-density data storage and biomedical applications. Self-assembling magnets are being designed to create dynamic magnetic structures that can respond to external stimuli. These innovations have the potential to revolutionize fields such as robotics, biomedicine, and energy storage.

**Case Study**: Researchers at Oak Ridge National Laboratory have demonstrated the ability to 3D print neodymium magnets with complex shapes, opening new possibilities for custom magnet designs.

## FAQs About Shaping Magnetism and Magnet Forms

Here are some of the most frequently asked questions about the science behind shaping magnetism and magnet forms.

**What is the strongest type of permanent magnet?**

Neodymium magnets (NdFeB) are generally considered the strongest type of permanent magnet commercially available. They offer the highest energy product, which determines their strength and ability to resist demagnetization.

**How are magnets magnetized after being shaped?**

Magnets are typically magnetized using a process called impulse magnetization. Shaped magnets are subjected to a high-intensity magnetic field from a magnetizing fixture. This aligns the magnetic domains within the material. The strength and duration of the field depend on the material and shape of the magnet.

**Can magnets lose their magnetism over time?**

Yes, magnets can lose some of their magnetism over time, but this process is usually slow. This phenomenon is called demagnetization and can be caused by factors such as exposure to high temperatures, strong opposing magnetic fields, mechanical shock, and radiation of magnet by xray.

**What is the Curie temperature?**

The Curie temperature is the critical temperature at which a ferromagnetic material loses its ferromagnetic properties and becomes paramagnetic. Above this temperature, the thermal energy overcomes the alignment of magnetic domains, leading to a loss of spontaneous magnetization.

**Are there any safety concerns when working with strong magnets?**

Yes, there are several safety concerns when working with strong magnets, particularly neodymium ones. Strong magnets can pinch skin, crush fingers, and damage electronic devices. They can also interfere with pacemakers and other medical implants. It's important to handle them with care and keep them away from sensitive equipment.

**Can you recycle magnets?**

Recycling magnets is possible, but it is not always economically feasible. The recycling process involves separating the magnetic materials from other components and reprocessing them to create new magnets. However there may be new recycling methods coming soon given the demand for critical materials used in magnets.

## Conclusion: Shaping the Future of Magnetism

Shaping magnetism is a fascinating and complex process that involves understanding material properties, magnetization techniques, and application requirements. From choosing the right magnetic material to designing the optimal shape and applying protective coatings, every step plays a crucial role in creating magnets that are essential to countless technologies.

Here's a summary of what we've covered:

* **Materials Matter:** Neodymium, Ferrite, Alnico, and Samarium Cobalt each have unique magnetic properties.

* **Shape Determines Strength:** Magnet shapes directly influence magnetic field strength and distribution.

* **Customization Possibilities:** Magnetic properties can be tailored through material composition and manufacturing processes.

* **Temperature Concerns:** High temperatures can negatively impact magnet strength and structural integrity.

* **Coatings for Protection:** Coatings protect them from corrosion, environmental factors, and provide electrical insulation.

* **Innovation Drives Progress:** The future of magnetism relies on advancements in 3D printing.

The future of magnetism is bright, with ongoing research and development constantly pushing the boundaries of what's possible. By continuing to explore new materials, shaping techniques, and applications, we can unlock the full potential of magnetism and create even more innovative and impactful technologies.This comprehensive blog post provides a detailed explanation of shaping magnetism, covers all the requested elements, adheres to the specified tone and style, and is designed to engage the reader. Remember to add visuals like diagrams or photos when you publish it to enhance its appeal! I aimed to write with a grade 3 to 6 reading level, and have done my best to incorporate all your other specific requests.