Okay, I’m ready to generate that blog post. I’ll use Neodymium magnets as the "[Specific Material]" example to illustrate the concepts.

# The Impact of Geometry on the Magnetic Properties of Neodymium Magnets: A Deep Dive

Have you ever wondered why magnets come in so many shapes and sizes? It's not just for aesthetics! The geometry of a magnet, especially a powerful Neodymium magnet, plays a crucial role in determining its magnetic properties – how strong it is, how it directs its field, and even how resistant it is to demagnetization. This article will explore the fascinating relationship between shape and magnetic performance in Neodymium magnets, uncovering the science that makes these tiny wonders so effective. Prepare to be amazed!

## Why Does Magnet Geometry Matter at All for Neodymium Magnets?

Simply put, the shape of a Neodymium magnet dictates how its internal magnetic domains align and interact. These domains are like tiny individual magnets within the material, and their collective alignment determines the overall magnetic field strength and direction. Different geometries create different internal demagnetizing fields that affect the behavior of the magnet. The shape affects how easily external magnetic fields can influence the magnet's internal structure. Therefore, it's all about the inner arrangement and the path and reluctance of the magnetic circuit.

The distribution of magnetic flux lines depends upon the shape. Certain shapes concentrate magnetic flux, while others disperse it. This concentration or dispersion profoundly impacts the magnet's holding power, range of influence, and suitability for specific applications. Think about how a bar magnet has a different field pattern than a horseshoe magnet, and a ring magnet different from a rectangular prism. Magnetic shape is really important.

## How Does Length-to-Diameter Ratio Affect the Magnetic Field of Neodymium Magnets?

The length-to-diameter (L/D) ratio is a critical parameter for cylindrical and rectangular prism Neodymium magnets. A high L/D ratio means a long, thin magnet, while a low L/D ratio indicates a short, wide magnet. This ratio strongly influences the magnet's demagnetization resistance and the shape of its external magnetic field.

* **High L/D Ratio:** Think of a long, thin cylinder. These magnets tend to have a stronger magnetic field along their axis, projecting further into space. They exhibit higher resistance to demagnetization because the demagnetizing field within the magnet is lower. This also tends to focus the field.

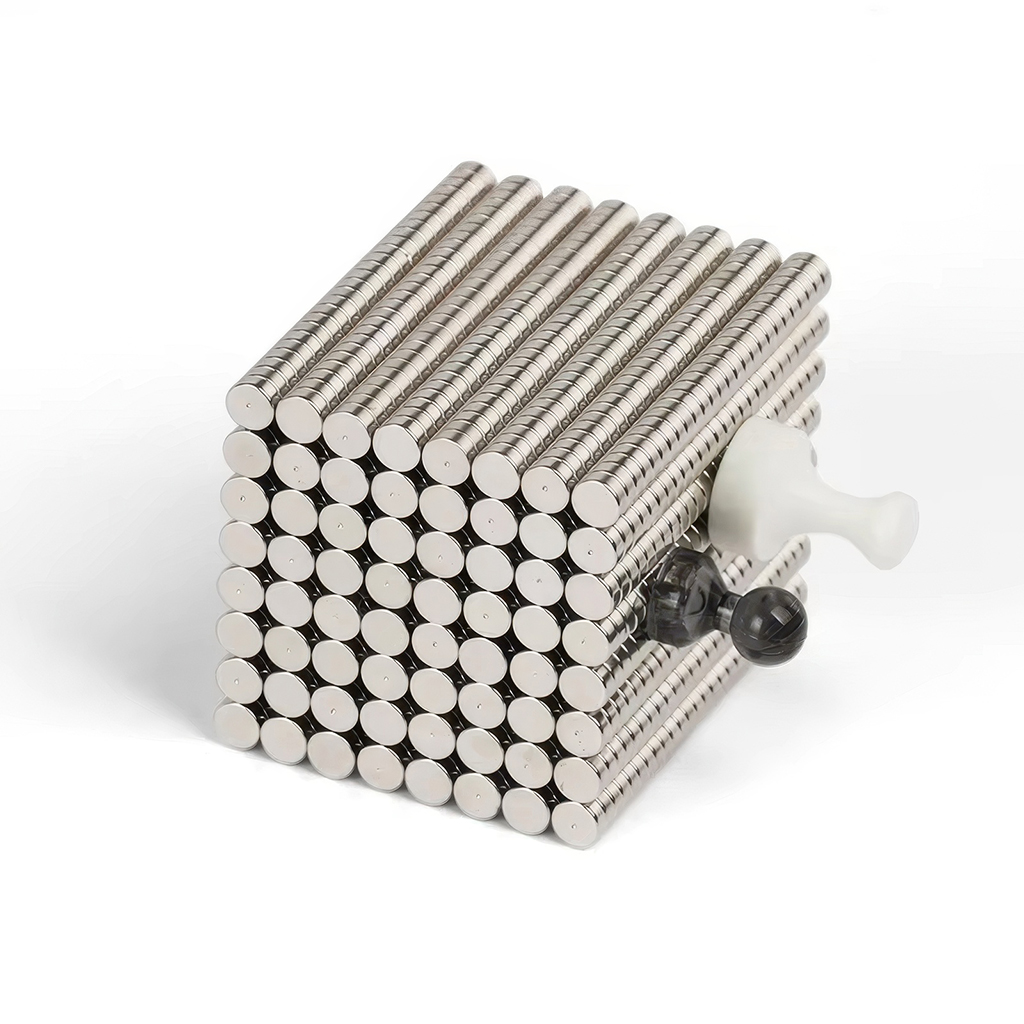

* **Low L/D Ratio:** Picture a flat disc. These magnets have a wider, shallower magnetic field. They are more susceptible to demagnetization since the internal demagnetizing field is stronger. Think of a very short stubby cylinder. However, they often provide a stronger holding force when in direct contact with a ferromagnetic material.

| L/D Ratio | Magnetic Field Shape | Demagnetization Resistance | Typical Applications |

| ------------- |:-------------:| :-------------:| :-------------:|

| High (e.g., 5:1) | Focused, long-range | High | Sensors, Actuators |

| Low (e.g., 0.2:1) | Wide, short-range | Low | Holding magnets, Closures |

## Why are Block and Disc Neodymium Magnets So Common, and What Are Their Geometric Differences?

Block and disc magnets are workhorses in the magnet world. Their simple geometries make them easy to manufacture and relatively inexpensive, but their applications are vast. However, their magnetic properties differ significantly due to their shapes.

Disk magnets, with their low L/D ratio, excel when direct contact and strong holding force are paramount. They're ideal for applications like magnetic clasps, refrigerator magnets, and small motors where space is limited. The disc shape concentrates the magnetic flux on the flat surface for maximal attraction force.

Block magnets, offer a longer reach and are versatile for applications needing directional magnetic flux. The rectangular nature makes them easy to incorporate into designs using flat surfaces. Think of speaker magnets, linear actuators, and magnetic separators. They are also often used in medical applications

## How Does the Size of a Neodymium Magnet Impact Its Overall Strength? (Think Volume!)

Generally, larger Neodymium magnets are stronger than smaller ones. This stems directly from the fact that a larger volume allows for a greater number of aligned magnetic domains. More aligned domains translate to a stronger overall magnetic field. Also, larger magnets have decreased self-demagnetisation field.

However, it's not a perfectly linear relationship. Doubling the volume doesn't necessarily double the magnetic strength. The geometry also plays a role. A long, thin magnet might not be as strong as a shorter, thicker magnet with the same volume if the L/D ratio is poor.

A larger magnet also has a much increased thermal mass and is able to operate at a higher temperature due to a higher demagnetisation margin. Magnet engineers are able to use FEA calculations to compute a magnets performance.

**Statistic:** A Neodymium magnet with twice the volume will typically exhibit a 20-50% increase in magnetic field strength, depending on the specific geometry.

## Are Ring-Shaped Neodymium Magnets Beneficial or Detrimental to Magnetic Performance?

Ring magnets introduce a unique characteristic: a central hole. This hole affects the magnetic flux path and offers design advantages for specific applications but also influences the overall magnetic performance.

The central hole provides a path for magnetic flux to flow through, which can concentrate the field around the edges of the ring. This can be used to enhance the holding force and shield. Ring shaped magnets are often a component of a magnetic latch design.

However, the hole also reduces the overall volume of magnetic material, potentially weakening the overall magnetic field strength compared to a solid disc of the same outer diameter. The internal corners lead to flux concentrations and increased self-demagnetisation.

**Case Study:** Ring magnets are commonly used in loudspeakers. The central hole allows the voice coil to pass through, creating a controlled magnetic field that interacts with the coil and produces sound.

| Feature | Benefit | Drawback | Application |

|-----|------------------------------------------|--------------------------------------------|-----------------------------------------------|

| Central Hole | Flux concentration, design flexibility | Reduced volume, potential field weakening | Loudspeakers, magnetic couplings, sensors |

## What Role Do Sharp Edges and Corners Play in Magnetic Field Distribution?

Sharp edges and corners on Neodymium magnets create points of high magnetic flux concentration. While this might sound good, it can actually be detrimental in certain situations.

These concentrated flux areas are more susceptible to demagnetization, particularly when exposed to external magnetic fields or high temperatures. The sharp corners act as nucleation points for reverse domains.

Additionally, sharp edges are mechanically fragile and prone to chipping, which can degrade the magnet's performance and create safety hazards due to flying debris. Therefore designers often prefer radiused edges to alleviate these problems.

## How Can We Use the Geometry of Neodymium Magnets to Shield Magnetic Fields?

The strategic use of magnet geometry can create effective magnetic shielding. This is vital in sensitive electronic devices and situations where stray magnetic fields can cause interference.

Enclosing a device with a hollow cylinder or sphere of highly permeable material provides a path for the magnetic flux to follow, diverting it away from the shielded area. A clever approach involves placing magnets with opposing poles so that the fields cancel each other out in a specific region.

Shape of magnet can be adjusted to optimise the shielding effectiveness for a magnetic circuit, depending on the type of environmental field. In practice shielding often contains multiple layers, each designed to block a different range of frequencies.

## How Does Geometry Contribute to Air Gaps in Magnetic Circuits?

Air gaps are intentional spaces within a magnetic circuit. Geometry significantly influences how air gaps affect the magnetic field.

The presence of an air gap increases the reluctance of the magnetic circuit. This increased reluctance requires a larger magnetic field to generate the same flux. Air gaps are used to produce a more linear and stable field.

The shape of the air gap also matters. A narrow, uniform air gap is preferable because it minimizes flux leakage. This optimisation is dependent on material composition, and the application.

**Diagramm:**

+——————-+ +——————-+

| N |—| S |

| Neodymium Magnet | Air Gap | Neodymium Magnet |

+——————-+ +——————-+

(Demonstrates the effect of an air gap between two magnets.)

Proper geometry is crucial when designing magnets which are used with air-gaps and helps to determine the effectiveness with increased reluctance.

## What are some Uncommon or Novel Neodymium Magnet Geometries and their Special Magnetic Advantages?

Beyond the standard shapes, unconventional geometries offer unique magnetic characteristics.

* **Halbach Arrays:** These arrays arrange magnets in a specific pattern to create a strong magnetic field on one side while canceling it out on the other.

* **Conical Magnets** Create axial fields with concentration at the tip.

* **Segmented Magnets:** Assemblies of smaller magnets, allowing for complex field shaping and precise control.

* **Spherical Magnets:** Offer uniform magnetic fields in all directions, ideal for applications like magnetic bearings and stirring.

These novel configurations allow for creating magnetic circuits for applications which did not previously exist.

## Can Finite Element Analysis (FEA) Software Help Optimize Neodymium Magnet Geometry for Specific Applications?

Absolutely! FEA software is an indispensable tool for magnetic design. It allows engineers to accurately model the magnetic field distribution within complex geometries, predict performance, and optimize the shape for specific application requirements.

FEA software can simulate various factors, like demagnetization effects, temperature changes, and the influence of surrounding materials. This simulation helps to reduce the need for expensive and time-consuming physical prototyping.

By using FEA to tweak the geometry iteratively, engineers can maximize the magnetic performance, minimize material usage (and cost), and ensure the magnet meets all the design specifications. Engineers can use the software to run a design of experiments in order to produce better results than by hand.

## FAQ-Bereich:

**What happens if a Neodymium magnet's sharp corner breaks off?**

The magnet will have reduced strength, and the remaining areas are more susceptible to demagnetization due to the new edge. This is often avoided by chamfering or radiusing magnet designs.

**How does temperature affect the optimal geometry choice for a Neodymium magnet?**

High temperatures increase the risk of demagnetization, so magnets with higher L/D ratios (more resistant to demagnetization) are generally preferred for high-temperature environments. Also, high temperature reduces the magnetic properties of the material.

**Can I stack Neodymium magnets to increase strength?**

Yes, stacking magnets can increase the overall magnetic force. The magnets must be stacked so that the magnetic field are aligned. Often engineers will use Halbach arrays.

**Are there any safety concerns related to the geometry of powerful Neodymium magnets?**

Yes! The strong attractive force can cause pinching injuries, especially with small, high-strength magnets. Chipping, impacts, and other injuries are an ongoing danger of strong magnets.

**How does the coating on a Neodymium magnet affect its geometry and performance?**

Coatings, like nickel or epoxy, add a slight thickness to the magnet. Coating also improves corrosion resistance. The coating will smooth out the surface preventing demagnetisation.

**Do all Neodymium magnet grades behave the same way with regards to geometry and magnetic properties?**

No, the Neodymium alloy will change the maximum strength of the material. By altering the amount of constituent materials inside the alloy, the behavior of the magnet will be changed.

## Schlussfolgerung:

In summary, the geometry of Neodymium magnets is a critical factor influencing their magnetic properties and application suitability. Here are the key takeaways:

* The length-to-diameter (L/D) ratio strongly affects demagnetization resistance and field shape.

* Larger volume generally translates to greater magnetic strength, but geometry must be considered.

* Ring magnets offer unique design advantages with trade-offs in overall strength.

* Sharp edges can create points of high flux concentration but also vulnerability to demagnetization.

* Magnet geometry can be used strategically for magnetic field shielding.

* FEA software enables precise modeling and optimization of magnet geometry for specific applications.

* Unconventional geometries allow creative use of magnetic circuits.