# Using Magnets and Copper for Eddy Current Braking: A Deep Dive

Ever wondered how those seemingly magical fairground rides suddenly stop smoothly without screeching brakes? Or how high-speed trains achieve controlled deceleration? The secret often lies in a fascinating application of physics: **eddy current braking**. This article explores the remarkable interplay between magnets and copper in this ingenious braking system. We’ll unravel the science behind it, examine its advantages, and discuss where you might encounter it in everyday life. So, buckle up as we delve into the world of magnets and copper, and discover the power of eddy current braking.

## What Exactly is Eddy Current Braking?

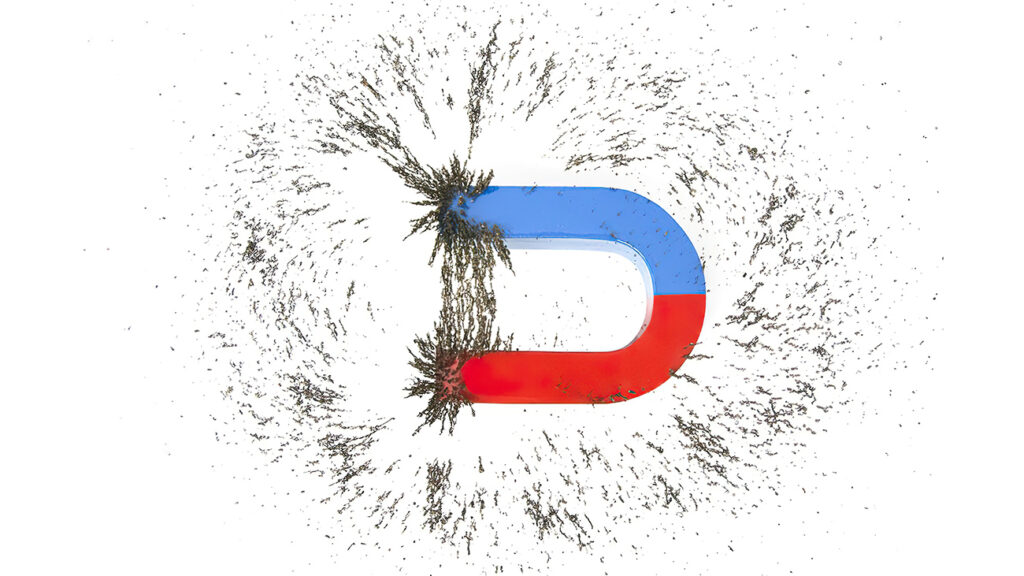

Eddy current braking is a non-contact braking method that uses the interaction between a magnetic field and a conductive material (typically copper or aluminum) to generate a braking force. Unlike traditional friction brakes, it doesn’t rely on physical contact, leading to smoother, quieter, and more reliable braking. Put simply, moving a conductor through a magnetic field induces circulating currents (eddy currents) within the conductor. These currents, in turn, generate their own magnetic field that opposes the original magnetic field, creating a force that slows down the moving object.

## How Does the Interaction of Magnets and Copper Cause Braking?

Let’s break down the core concept. Imagine a powerful magnet held near a rotating copper disc.

* **Motion and Magnetic Field:** As the copper disc spins, it’s essentially moving through the magnet’s magnetic field lines.

* **Electromagnetic Induction:** According to Faraday’s Law of electromagnetic induction, a changing magnetic field through a conductor induces a voltage, which drives a current.

* **Eddy Currents:** This induced voltage creates circulating currents within the copper disc. These are the “eddy currents,” so-named because they resemble eddies in a stream.

* **Lenz’s Law and Braking Force:** These eddy currents generate their own magnetic field. Lenz’s Law states that this induced magnetic field opposes the change that created it. In this case, it opposes the motion of the copper disc, resulting in a braking force. The faster the disc spins, the stronger the eddy currents, and the greater the braking force.

## Why is Copper Primarily Used in Eddy Current Brakes?

While other materials like aluminum can be used, copper is often preferred in eddy current brakes due to its superior electrical conductivity. Here’s why:

* **High Electrical Conductivity:** Copper possesses excellent electrical conductivity, allowing eddy currents to flow with minimal resistance. This translates to stronger eddy currents and a more effective braking force. Imagine trying to run in thick mud versus on a paved road. Copper is like the paved road for electrons.

* **Cost-Effectiveness:** While silver is even more conductive, copper strikes a good balance between performance and cost.

**Fact:** Copper’s electrical conductivity is approximately 59.6 x 10^6 S/m at 20°C. This significantly contributes to the efficiency of eddy current braking systems.

## What are the Key Advantages of Eddy Current Braking Systems?

Eddy current brakes offer several significant advantages over traditional friction brakes:

* **Non-Contact Braking:** This eliminates wear and tear, leading to longer lifespan and reduced maintenance. No brake pads to replace!

* **Smooth and Quiet Operation:** The absence of physical contact results in smooth and quiet deceleration.

* **Controllability:** The braking force can be easily controlled by adjusting the strength of the magnetic field or the speed of the moving conductor.

* **Reliability:** Fewer moving parts mean fewer potential points of failure.

## Where Are Eddy Current Brakes Commonly Found?

You might be surprised where you can find this technology in action!

* **Roller Coasters and Amusement Park Rides:** Eddy current brakes provide smooth and controlled deceleration, ensuring a safe and enjoyable ride.

* **High-Speed Trains:** Some trains utilize eddy current brakes as a supplementary braking system alongside traditional friction brakes and regenerative braking.

* **Dynamometers:** Dynamometers, used to measure the torque and power of engines, often employ eddy current brakes to apply a load to the engine.

* **Textile Machinery:** Eddy current brakes are used for precise tension control in various stages of textile manufacturing.

**Case Study:** Many modern roller coasters use eddy current brakes as the primary stopping mechanism. These brakes offer a smooth and predictable stopping experience, enhancing rider safety and comfort. This leads to less jerk on the body and a smoother overall ride.

"Meerjungfrau

Grafik LR

A[Motion of Conductor (e.g., Copper Disc)] –> B(Magnetic Field from Magnet);

B –> C{Electromagnetic Induction};

C –> D[Eddy Currents in Conductor];

D –> E(Induced Magnetic Field Opposing Motion);

E –> F(Braking Force);

How Does Magnetic Field Strength Affect Braking Performance?

The strength of the magnetic field is directly proportional to the braking force generated by an eddy current brake. A stronger magnetic field induces larger eddy currents, leading to a more powerful opposing magnetic field and increased braking force. Utilizing stronger magnets significantly amplifies the effectiveness of the braking system. This makes understanding and selecting appropriate magnet materials extremely important in its effective operation.

What Role Does Copper Plate Thickness Play in Braking Efficiency?

The thickness of the copper plate also impacts braking efficiency, though with diminishing returns. A thicker plate offers more volume for eddy currents to circulate, initially leading to increased braking force. However, beyond a certain thickness, the core of the plate may not contribute significantly to current flow due to the “skin effect,” where eddy currents tend to concentrate near the surface.

Statistische Daten: Studies have shown that increasing copper plate thickness offers diminishing returns beyond a certain point, as the skin effect limits the effective current-carrying volume.

How Does Temperature Impact the Performance of Eddy Current Brakes?

Temperature can affect the performance of eddy current brakes. As the temperature of the copper increases, its electrical conductivity decreases, which reduces the magnitude of the eddy currents and the resulting braking force. Furthermore, extremely high temperatures can potentially demagnetize permanent magnets, severely impacting the brake’s effectiveness.

Here’s a table summarizing the effect:

| Faktor | Impact on Braking Force | Erläuterung |

|---|---|---|

| Magnetische Stärke | Increased | Stronger magnets create increased eddy current flow, creating increased force |

| Copper Thickness | Initially increased, then diminishing returns | Skin effect limitations |

| Temperatur | Decreased | Increased heat reduces the conductive ability of the copper |

Can Eddy Current Brakes be Used for Precise Position Control?

Yes! Because the braking force is proportional to the velocity of the moving object and magnitude of the magnetic field, eddy current brakes can be integrated into feedback control systems for precise position control applications. By carefully adjusting the magnetic field strength using electromagnets, engineers can achieve highly accurate and responsive positioning. This is especially useful in robotics and industrial automation.

Are There Any Disadvantages to Using Eddy Current Brakes?

While eddy current brakes offer many benefits, they also have some limitations:

- Speed Dependency: The braking force is proportional to the speed of the moving object. This means they are less effective at very low speeds or when holding a static load. This is because slower speeds create less electromagnetic induction.

- Heat Generation: Eddy currents generate heat within the conductor, which can require cooling systems in high-power applications. This heat is due to the resistance in the copper (or whichever conductive material is being used).

- Kosten: High-performance magnets (like neodymium) can be expensive, potentially increasing the overall cost of the system.

FAQ-Abschnitt:

Why don’t all vehicles use eddy current brakes?

Eddy current brakes are not suitable as the sole braking system for all vehicles due to their speed dependency. They are most effective at higher speeds and require a backup braking system, such as friction brakes, for low-speed stops and holding the vehicle in place. Furthermore, the cost of implementing eddy current brakes can be a factor in many vehicles’ design.

What types of magnets are used in eddy current brakes?

Commonly, strong permanent magnets like neodymium magnets are selected in eddy current brakes. These magnets offer a high magnetic field strength in a compact size. Electromagnets can also be used, however, they add complexity, cost and require a constant power supply.

Are eddy current brakes environmentally friendly?

Yes, eddy current brakes are generally considered environmentally friendly because they don’t produce particulate matter like brake dust, which is a concern with traditional friction brakes.

How are eddy current brakes maintained?

Because they are non contact brakes they typically require very little maintenance, primarily limited to ensuring the magnets are properly secured and cooling systems (if present) are functioning correctly.

Can eddy current brakes be used in electric vehicles?

Yes, eddy current braking can be used in electric vehicles. However, the regenerative braking systems common in EVs are more efficient at recovering energy and are often preferred. They can be implemented to supplement regenerative braking at higher speeds.

How do you calculate the braking force of an eddy current brake?

The braking force is fairly complex, but it is dependent on:

- Speed of conductor.

- Magnetic Field Strength.

- Conductivity of material.

- Geometry of the magnetic field and conductor.

Schlussfolgerung:

In conclusion, eddy current braking is a fascinating and effective technology that leverages the interaction of magnets and copper to provide smooth, reliable, and non-contact braking. While not a replacement for traditional braking systems in all applications, its unique advantages make it ideal for specific uses like roller coasters, high-speed trains, and dynamometers. Understanding the principles and applications of eddy current braking provides valuable insights into the world of electromagnetism and its impact on various technologies.

Hier sind die wichtigsten Erkenntnisse:

- Eddy current braking uses the interaction between magnets and copper to generate a braking force.

- Copper’s high electrical conductivity makes it an ideal material for eddy current brakes.

- Eddy current brakes offer smooth, quiet, and reliable braking compared to traditional friction brakes.

- They are commonly used in roller coasters, high-speed trains, and dynamometers.

- Magnetic field strength, copper thickness, and temperature affect braking performance.

- While beneficial, they have limitations regarding speed dependency and heat generation.