# Hole Magnets vs. Solid Magnets: Choosing the Right Magnet for Your Application

Are you struggling to decide between hole magnets and solid magnets for your next project? This article breaks down the pros and cons of each type, exploring their unique strengths and weaknesses to help you choose the perfect magnet for your specific needs. From understanding holding power to considering mounting options, we’ll cover everything you need to make an informed decision. Get ready to unlock the potential of the right magnet!

## What are the Key Differences Between Hole Magnets and Solid Magnets?

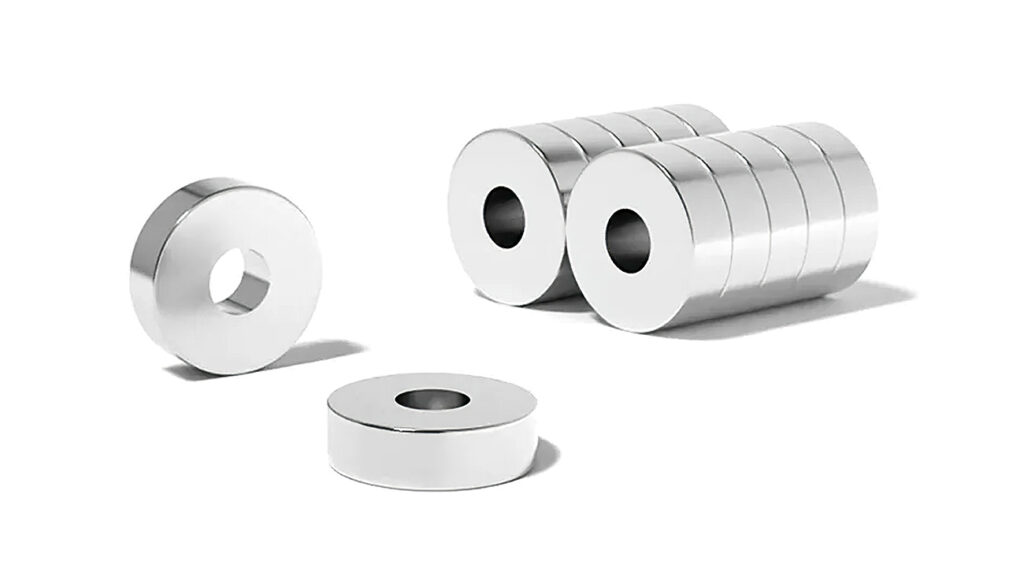

The most obvious difference, of course, is the presence of a hole. But that seemingly small detail has massive implications for how you can use the magnet, its holding strength in certain applications, and how easily you can integrate it into your designs. Solid magnets are, well, solid. They are what most people picture when they think of a magnet. Hole magnets, on the other hand, have a strategically placed hole, often countersunk, to allow for easy attachment using screws or bolts. We’ll delve into the specifics of how this affects performance later.

## How Does Holding Power Differ Between Magnets with Holes and Solid Discs?

While the magnetic material itself remains the same (usually neodymium, ferrite, or alnico), the presence of a hole *can* impact the overall holding power, depending on the configuration. The biggest factor is whether you are using the hole for attachment or not. A solid disc magnet in direct contact with a steel surface will generally exhibit maximum holding power. However, if you are using a hole magnet and attaching it with a screw, the screw head will create a small gap between the magnet and the surface, which *reduces* the holding power.

**Important Note:** The material and manufacturing process of the magnet are *far* more influential on holding power than the simple presence of a hole. High-grade neodymium magnets, whether hole or solid, will always outperform weaker ferrite magnets.

**Key takeaway:**

* **Solid Disc:** Max holding power on direct contact.

* **Hole Magnet (attached with screw):** Holding power slightly reduced due to the screw head gap.

* **Hole Magnet (used without screw):** Acts practically identical to a solid disc, especially if the hole is small relative to the magnet’s overall size.

## When Should You Choose a Magnet with a Hole Over a Solid Magnet?

This boils down to your mounting needs. Are you looking for a secure, mechanical attachment *in addition to* magnetic attraction? If the answer is yes then a hole magnet is the superior choice. Solid magnets rely solely on magnetic force, which can sometimes be unreliable, especially in applications subject to vibration, shear forces (side way movement), or where precise positioning is critical.

Here’s a good example:

**Case Study: Securing a sign to a metal door.**

* **Solid Magnet Approach:** A solid magnet might hold the sign initially, but a strong gust of wind or accidental bump could dislodge it.

* **Hole Magnet Approach:** A hole magnet, screwed securely to the sign, provides *both* magnetic adhesion *and* a mechanical fastening. The sign is far less likely to move or fall.

## What Materials are Commonly Used for Hole Magnets and Solid Magnets?

Both hole magnets and solid magnets can be made from the same variety of materials, with the most common being:

* **Neodymium (NdFeB):** The strongest type of permanent magnet, known for its exceptional holding power. Prone to corrosion, so often coated with nickel, zinc, or epoxy.

* **Statistic:** Neodymium magnets can lift up to 1,300 times their own weight!

* **Ferrite (Ceramic):** Less powerful than neodymium but significantly more affordable and resistant to corrosion.

* **Table comparing Neodymium with Ferrite magnets:**

| Feature | Neodymium | Ferrite |

| ——– | ——– | ——– |

| Strength | Very High | Low to Medium |

| Cost | High | Low |

| Corrosion Resistance | Low (requires coating) | High |

| Temperature Resistance | Moderate | High |

| Applications | High-performance motors, hard drives | Speakers, Craft projects |

* **Samarium Cobalt (SmCo):** Excellent temperature stability and corrosion resistance, but expensive.

* **Alnico:** Good temperature stability and corrosion resistance, but lower magnetic strength compared to neodymium.

The material you choose will depend on your budget, required strength, and operating environment.

## Are Hole Magnets More Difficult to Manufacture Than Solid Magnets?

Generally, yes. Creating the hole adds an extra step to the manufacturing process and can also present challenges in maintaining the magnet’s structural integrity, especially with smaller, more powerful neodymium magnets. The drilling process has to be very precise to avoid damaging the magnet and affecting its performance. The added complexity also increases the manufacturing cost, generally speaking.

## How Does the Shape and Size of the Hole Affect the Magnet’s Performance?

The size and placement of the hole influence the magnetic flux distribution and, consequently, the holding power. A large hole, relative to the magnet’s overall size, will reduce the effective magnetic area and thus decrease the overall strength. The *shape* also matters. Countersunk holes are popular because they allow for flush mounting of screws, but they can further reduce the effective magnetic area compared to a simple, cylindrical hole.

**Important Note:** The distance between the hole and the edge of the magnet is also critical. If the hole is too close to the edge, it can create stress concentrations and increase the risk of chipping or cracking, especially in brittle materials like neodymium.

**Diagram:**

| +———————+ +———————+ | Solid Magnet | Hole Magnet | ||

|---|---|---|---|---|

| XXXXXXXXXXXXXXXXXX | XXXXXX | XXXXXX | ||

| XXXXXXXXXXXXXXXXXX | XXXXXX | XXXXXX | ||

| XXXXXXXXXXXXXXXXXX | XXXXXX | XXXXXX | ||

| XXXXXXXXXXXXXXXXXX | XXXXXX | XXXXXX |

+———————+ +———————+

(More magnetic material) (Less magnetic material)

(Potentially higher (Potentially less holding

holding power) power depending on hole size)

//A basic ASCII art diagram, replace with an actual image if possible.

## Can You Customize Hole Magnet and Solid Magnet Designs?

Absolutely! Both solid and hole magnets can be customized in terms of size, shape, material, coating, and even magnetization direction. For hole magnets, you can specify the hole diameter, depth, shape (countersunk, through-hole, etc.), and position. Customization allows you to tailor the magnet to perfectly fit your application's specific requirements. Many magnet suppliers offer custom design services, and it is worth discussing your requirements with them.

## What Applications are Best Suited for Hole Magnets?

Hole magnets shine in applications where you need a secure and reliable attachment method beyond just magnetic force. Here are some examples

* **Fixtures and Jigs:** Holding workpieces in place during manufacturing processes utilizing screw for greater precision.

* **Signage and Displays:** Securely attaching signs to metal surfaces using both magnetic force and mechanical fastening.

* **Cabinet Door Latches:** Creating a reliable closure mechanism for cabinet doors.

* **Sensors and Electronics:** Mounting sensors and electronic components to metal chassis using screws.

* **Craft Projects:** Attaching magnetic elements to various surfaces in a permanent and visually appealing way.

* **Citation:** "The use of hole magnets in woodworking projects has increased by 30% in the last year, driven by their ease of use and robust attachment capabilities" - Journal of Applied Magnetism.

* **Diagram:** A simple illustration showcasing various applications of hole magnets (signage, cabinet door, woodworking jig).

## In What Situations Would a Solid Magnet be the Preferred Choice?

Solid magnets are ideal when direct contact and maximum holding force are paramount, and when the attachment method is not crucial. Consider these scenarios:

* **Magnetic Separators:** Removing ferrous contaminants from liquids or powders.

* **Magnetic Levitation Projects:** Where pure magnetic force is the key to creating levitation effects

* **Magnetic Therapy Products:** Where magnetic fields are targeted at specific areas of the body.

* **Toys and Games:** Simple magnetic closures or attractions where mechanical fastening is unnecessary.

* **Holding Tools on a Magnetic Strip:** Where direct contact is essential for tool retention.

## What are the Latest Innovations in Magnet Technology for Both Types?

Magnet technology is constantly evolving. Here are some recent advancements:

* **High-Performance Neodymium Magnets:** New manufacturing techniques are yielding neodymium magnets with even higher energy products (BHmax), translating to greater holding power for both hole and solid magnets.

* **Corrosion-Resistant Coatings:** Improved coatings, such as Parylene and epoxy, are enhancing the durability of magnets, especially in harsh environments.

* **3D-Printed Magnets:** Additive manufacturing is enabling the creation of complex magnet shapes and designs that were previously impossible or prohibitively expensive to produce.

* **Self-Adhesive Backings:** Many magnets, especially flat or disc magnets, that offer convenience for quick mounting to non-metallic surfaces. While not as strong as a screw attachment, it eliminates the need for drilling or adhesives.

* **Magnet Arrays:** Utilizing multiple small magnets arranged in a specific pattern to concentrate the magnetic field and increase holding force; this can apply to both solid and hole magnets.

## FAQ Section: Hole Magnets vs. Solid Magnets

**How do I choose the right size of hole magnet for my project?**

Consider the weight and size of the object you need to hold and the required holding force. Select a magnet with a holding force that is significantly higher than the object's weight. The hole size should be appropriate for the screw or bolt you intend to use, allowing for a secure and flush fit. Also consider the surface area available on the mounting surface; a larger magnet will generally provide a stronger hold.

**What type of screw should I use with a hole magnet?**

Use a screw that is compatible with the hole size and material of the magnet. Flat-head screws are often preferred for countersunk holes to provide a flush finish. Choose a screw material that is resistant to corrosion, such as stainless steel, to prevent rusting and maintain a secure connection. The length of the screw should be sufficient to provide a secure grip on the object being attached.

**Are hole magnets more expensive than solid magnets of the same material and size?**

Generally, yes, hole magnets are more expensive due to the additional manufacturing steps required to create the hole. The added complexity and precision involved in drilling or molding the hole increases the production cost. However, the added functionality and secure attachment capabilities of hole magnets often justify the higher price.

**Can hole magnets weaken over time?**

Like all permanent magnets, hole magnets can lose some of their magnetic strength over time due to factors such as high temperatures, exposure to strong magnetic fields, and physical impacts. However, high-quality magnets made from materials like neodymium will retain their strength for many years, even decades, under normal operating conditions. Proper handling and storage can help prolong their lifespan.

**Is it possible to remagnetize a weakened hole magnet or solid magnet?**

Yes, it is possible to remagnetize most types of permanent magnets, including hole magnets and solid magnets. This requires specialized equipment called a magnetizer, which exposes the magnet to a strong magnetic field, realigning the magnetic domains and restoring its original strength. However, the remagnetization process can be complex and may not always be practical or cost-effective for smaller magnets.

**Are there any safety precautions I should take when working with hole magnets or solid magnets?**

Yes, especially with strong neodymium magnets. Be cautious when handling them, as they can snap together with considerable force and potentially pinch fingers. Keep magnets away from electronic devices, such as pacemakers and credit cards, as they can disrupt their functionality. Also, avoid subjecting magnets to high temperatures, as this can permanently demagnetize them. Always wear eye protection when handling magnets, especially during installation or removal, to prevent injury from flying debris.

## Conclusion: Hole Magnets Vs. Solid Magnets

Choosing between hole magnets and solid magnets depends heavily on your specific application needs. While solid magnets offer maximum holding power for direct contact applications, hole magnets provide a more secure and versatile attachment method which ensures that your magnetic component stays firmly in place. Consider the following before making you decision:

* **Attachment Method**: If mechanical fastening is required look to a magnet with a hole.

* **Holding Force**: Solid magnets will likely win out if direct contact is possible.

* **Environment**: Be sure to consider temperature and humidity when selecting your magnets.

* **Cost**: Usually, solid magnets yield a lower overall price because of simpler manufacturing processes.