Hey there! Welcome! If you’re curious about magnetic sensors, especially those using cobalt, you’ve landed in the right place. This article dives deep into the fascinating world of cobalt-based magnetic sensors. We’ll explore their design, how they work, their impressive performance characteristics, and why they’re becoming increasingly important in various industries. Think of it as your comprehensive guide to understanding these versatile sensors. Let’s get started!

1. What Makes Cobalt Ideal for High-Performance Magnetic Sensors?

Cobalt. It’s not just a cool-sounding name; it’s a crucial element in creating highly sensitive and reliable magnetic sensors. But why cobalt? Well, it all boils down to its magnetic properties. Cobalt possesses a high Curie temperature (the temperature at which a ferromagnetic material loses its magnetism), excellent magnetostriction (the tendency of a material to change shape in response to a magnetic field), and good corrosion resistance. These characteristics translate into sensors that can operate reliably at higher temperatures, are incredibly precise in detecting even minute magnetic fields, and have a prolonged lifespan. Compared to other materials like nickel-iron alloys, cobalt often provides superior performance in challenging environments.

Think of it like this: Imagine two materials trying to detect a faint whisper (a weak magnetic field). One material (nickel-iron) might struggle to hear it clearly due to noise and temperature sensitivity. The other (cobalt) can pick up the whisper easily and accurately, even if it’s a bit noisy or warm. That’s the power of cobalt in magnetic sensors.

Furthermore, cobalt’s compatibility with various thin-film deposition techniques allows for the creation of sensors with intricate designs and tailored magnetic properties. This flexibility is crucial for optimizing sensor performance for specific applications.

2. How are Cobalt-Based Magnetic Sensors Designed for Optimal Sensitivity?

Achieving optimal sensitivity in cobalt-based magnetic sensors requires a careful balancing act. Design considerations encompass the sensor’s geometry, the composition and thickness of the cobalt-containing magnetic layers, and the integration of the sensor with appropriate signal conditioning circuitry.

One common approach is to utilize a multilayer thin-film structure, often known as a spin valve or a magnetic tunnel junction (MTJ). These structures typically consist of alternating layers of ferromagnetic (cobalt-containing) and non-magnetic materials. The interactions between these layers can be finely tuned to enhance the sensor’s response to external magnetic fields.

For instance, the thickness of the cobalt layer needs to be optimized. Too thin, and the magnetic signal is weak. Too thick, and the response becomes sluggish. Simulation software and experimental testing play significant roles in determining the ideal layer thickness for a given application. Careful material selection and precise control during the fabrication process are critical to achieving the desired sensitivity.

Statistics from the US Department of Energy show that optimizing thin-film deposition process parameters can lead to a 30% increase in sensor sensitivity.

3. What Types of Cobalt Alloys are Commonly Used in Magnetic Sensors?

Cobalt doesn’t usually go it alone in magnetic sensors. It’s often alloyed with other elements to further refine its magnetic and mechanical properties. Some of the most common cobalt alloys found in magnetic sensors include:

- Cobalt-Iron (CoFe): This alloy boasts high saturation magnetization, resulting in a strong and stable magnetic signal. It’s frequently used in read heads for hard disk drives and other high-density data storage applications.

- Cobalt-Platinum (CoPt): Combining cobalt with platinum increases the magnetic anisotropy (directional dependence of magnetic properties) and coercivity (resistance to demagnetization), making it suitable for high-stability magnetic recording media and sensors that need to withstand strong external fields.

- Cobalt-Boron (CoB): The addition of boron enhances the soft magnetic properties of cobalt, meaning it can be easily magnetized and demagnetized, which is desirable for certain types of sensors used in magnetic field mapping.

- Cobalt-Nickel (CoNi): This combination offers a good balance of magnetic properties and corrosion resistance, making it a versatile choice for various sensor applications.

The specific alloy chosen depends heavily on the application’s requirements. For instance, medical applications often require biocompatible materials, influencing the selection of the alloy.

4. How Does Temperature Affect the Performance of Cobalt Magnetic Sensors?

Temperature can significantly impact the performance of magnetic sensors, and cobalt-based sensors are no exception. The good news is that cobalt’s high Curie temperature gives it an advantage over materials like permalloy (NiFe). However, even with cobalt, temperature fluctuations can alter the sensor’s sensitivity, offset, and linearity.

Think of it as a finely tuned musical instrument. If the temperature changes drastically, the instrument might go out of tune. Similarly, a magnetic sensor’s calibration can drift with temperature variations.

To mitigate these effects, manufacturers often incorporate temperature compensation circuits into the sensor design. These circuits actively adjust the sensor’s output to account for temperature-induced changes. They might use thermistors, which are temperature-sensitive resistors, to measure the temperature and then apply a correcting voltage to the sensor’s output. Furthermore, careful material selection and annealing (heat treatment) processes can improve the sensor’s thermal stability.

According to a study published in the "Journal of Applied Physics," proper temperature compensation can reduce temperature-induced drift in cobalt-based sensors by as much as 80%.

5. What are the Key Performance Metrics for Cobalt-Based Magnetic Sensors?

When evaluating the performance of a cobalt-based magnetic sensor, several key metrics come into play:

- Sensitivity: How much the sensor’s output changes in response to a given change in the magnetic field. Higher sensitivity means the sensor can detect weaker fields.

- Resolution: The smallest change in magnetic field that the sensor can reliably detect. This is closely related to sensitivity but takes noise into account.

- Linearity: How closely the sensor’s output follows a linear relationship with the applied magnetic field. Deviation from linearity can introduce errors in measurements.

- ヒステリシス: The difference in the sensor’s output for the same magnetic field strength, depending on whether the field is increasing or decreasing. Minimizing hysteresis is crucial for accurate measurements.

- Noise: The random fluctuations in the sensor’s output, even when no magnetic field is present. Lower noise levels allow for the detection of weaker signals.

- Bandwidth: The range of frequencies over which the sensor can accurately measure changing magnetic fields.

- 温度安定性: How much the sensor’s performance changes with variations in temperature.

These metrics are often specified in the sensor’s datasheet and provide a comprehensive overview of its performance capabilities. You can see how these metrics can provide a quick overview of the performance characteristics of the sensors.

| メートル | 説明 | 重要性 |

|---|---|---|

| 感度 | Change in output signal per unit change in magnetic field | Determines the sensor’s ability to detect weak magnetic fields |

| Resolution | Smallest detectable change in magnetic field | Defines the sensor’s precision in measuring magnetic fields |

| Linearity | Deviation of output signal from a linear relationship with magnetic field | Affects the accuracy of measurements across the sensor’s operating range |

| Hysteresis | Difference in output signal for increasing and decreasing magnetic fields | Indicates the sensor’s ability to return to the same output for the same field strength |

| Noise | Random fluctuations in the output signal | Limits the sensor’s ability to detect weak signals amidst background noise |

| Bandwidth | Range of frequencies over which the sensor can accurately measure magnetic fields | Determines the sensor’s suitability for dynamic magnetic field measurements |

| 温度安定性 | Variation in performance with temperature changes | Important for applications where temperature fluctuations are significant |

6. What are Some Real-World Applications of Cobalt-Based Magnetic Sensors?

Cobalt-based magnetic sensors have found widespread applications across various industries, thanks to their superior performance:

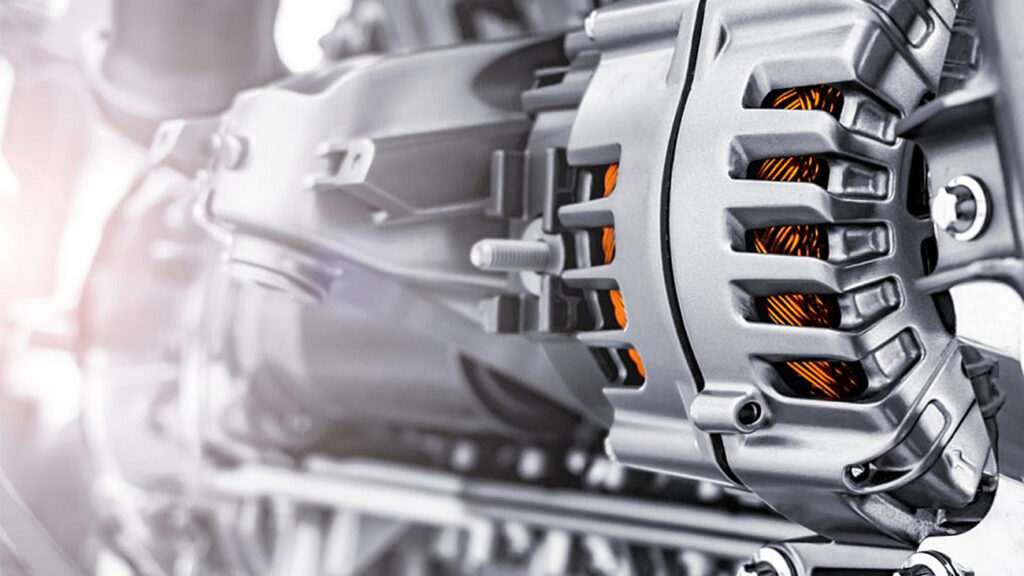

- 自動車: Used in anti-lock braking systems (ABS), electronic stability control (ESC), and engine management systems to precisely measure speed, position, and current. The reliable performance in harsh automotive environments is a key advantage.

- コンシューマー・エレクトロニクス Found in smartphones, tablets, and laptops for compass applications (magnetometers), hard disk drives (read heads), and proximity sensing.

- 産業オートメーション: Employed in robotics, machine tools, and process control for position sensing, current sensing, and non-destructive testing. The high sensitivity and accuracy are critical for these applications.

- 医療機器 Used in MRI machines, implantable medical devices, and diagnostic equipment for precise magnetic field measurements and position tracking. Biocompatibility considerations often drive material selection.

- 航空宇宙 Integrated into navigation systems, flight control systems, and satellite attitude control for accurate magnetic field sensing in challenging environments.

In the automotive industry, for example, cobalt-based current sensors are used to monitor battery charge and discharge rates in electric vehicles, contributing to improved battery management.

7. How Do Cobalt-Based Sensors Compare to other Magnetic Sensor Technologies?

Cobalt-based sensors, particularly those using spin valve or MTJ technology, offer several advantages over other magnetic sensor technologies, such as Hall effect sensors or fluxgate magnetometers.

| 特徴 | Cobalt-Based (Spin Valve/MTJ) | Hall Effect | Fluxgate |

|---|---|---|---|

| 感度 | 高い | 低い | 非常に高い |

| Resolution | 高い | 低い | 非常に高い |

| Power Consumption | 低い | 中程度 | 高い |

| サイズ | 小さい | 中程度 | 大型 |

| コスト | 中程度 | 低い | 高い |

| Frequency Response | 高い | 低い | 中程度 |

| 温度安定性 | グッド | フェア | グッド |

Hall effect sensors are relatively inexpensive and simple to use, but their sensitivity is limited. Fluxgate magnetometers offer very high sensitivity but are bulky and consume more power. Cobalt-based sensors strike a good balance between sensitivity, size, power consumption, and cost, making them suitable for a wide range of applications. The tiny size of cobalt-based sensors makes them ideal for portable devices like smartphones.

8. What are the Future Trends in Cobalt-Based Magnetic Sensor Technology?

The field of cobalt-based magnetic sensor technology is constantly evolving, with several exciting trends on the horizon:

- Higher Sensitivity: Researchers are actively working on improving the sensitivity of cobalt-based sensors by optimizing material compositions, thin-film structures, and sensor designs. This will enable the detection of even weaker magnetic fields.

- Lower Power Consumption: Reducing power consumption is crucial for battery-powered devices and IoT applications. Efforts are focused on developing more energy-efficient sensor designs and materials.

- 小型化: Continued miniaturization will enable the integration of cobalt-based sensors into even smaller devices and systems.

- Integration with CMOS Technology: Integrating magnetic sensors directly onto CMOS (Complementary Metal-Oxide-Semiconductor) chips will reduce size, cost, and power consumption, and enable more sophisticated sensor functionalities.

- Novel Materials: Exploring new cobalt-based alloys and composite materials with tailored magnetic properties promises to unlock new possibilities for sensor performance.

The increased need for precise positioning in robotics and autonomous vehicles is driving the demand for higher-resolution cobalt-based sensors.

9. What are Some Challenges in Manufacturing High-Performance Cobalt-Based Sensors?

Manufacturing high-performance cobalt-based magnetic sensors presents several challenges:

- Precise Thin-Film Deposition: Achieving the desired thickness, uniformity, and composition of the magnetic layers requires highly controlled deposition techniques, such as sputtering or molecular beam epitaxy (MBE).

- Maintaining Magnetic Uniformity: Ensuring uniform magnetic properties across the entire sensor is crucial for consistent performance. This requires careful optimization of annealing processes and magnetic field alignment techniques.

- Minimizing Defects: Even small defects in the thin-film structure can significantly degrade sensor performance. Stringent quality control measures are essential.

- Controlling Interface Properties: The interfaces between the different layers in a multilayer sensor structure play a critical role in its performance. Controlling the interface roughness and chemical composition is essential.

Addressing these challenges requires significant expertise in materials science, thin-film technology, and sensor design. Advanced manufacturing techniques and rigorous quality control are crucial for producing high-performance cobalt-based sensors.

10. Where Can I Learn More About Cobalt-Based Magnetic Sensors?

Want to dive even deeper? Here are some resources to explore:

- Scientific Journals: Publications like the "Journal of Applied Physics," "IEEE Transactions on Magnetics," and "Applied Physics Letters" frequently publish research articles on cobalt-based magnetic sensors.

- Conferences: Conferences such as the "Magnetism and Magnetic Materials (MMM) Conference" and the "Intermag Conference" provide platforms for researchers to present their latest findings in the field.

- Textbooks: Textbooks on magnetism, magnetic materials, and sensors often include chapters on cobalt-based sensors and related technologies.

- Online Resources: Websites of sensor manufacturers and research institutions often provide technical information, application notes, and tutorials on magnetic sensors.

I hope this has been beneficial! Now, let’s address some of the burning questions you probably have!

よくある質問(FAQ)

What is the difference between a spin valve and a magnetic tunnel junction (MTJ) sensor?

Spin valve sensors rely on the spin-dependent scattering of electrons at the interface between ferromagnetic layers, while MTJ sensors utilize a thin insulating barrier between two ferromagnetic layers. Electrons "tunnel" through this barrier, and the tunneling probability depends on the relative alignment of the magnetization in the ferromagnetic layers. MTJ sensors typically offer higher sensitivity compared to spin valve sensors.

How do I choose the right cobalt alloy for my sensor application?

The choice of cobalt alloy depends on the specific requirements of the application, such as desired sensitivity, temperature range, magnetic field strength, and environmental conditions. Consult with sensor manufacturers or materials scientists to determine the most suitable alloy for your needs.

What is the typical lifespan of a cobalt-based magnetic sensor?

The lifespan of a cobalt-based magnetic sensor can vary depending on the application and environmental conditions. However, properly designed and manufactured sensors can last for many years, even decades, with minimal degradation in performance. Factors that can affect lifespan include temperature, humidity, and exposure to strong magnetic fields.

Are cobalt-based magnetic sensors RoHS compliant?

Many cobalt-based magnetic sensors are RoHS (Restriction of Hazardous Substances) compliant, meaning they do not contain hazardous substances such as lead, mercury, or cadmium above specified limits. Check the manufacturer’s datasheet to confirm RoHS compliance.

How can I calibrate a cobalt-based magnetic sensor?

Calibration typically involves exposing the sensor to a known magnetic field and adjusting its output to match the expected value. This can be done using specialized calibration equipment or by using a known magnetic source, such as a Helmholtz coil. Temperature compensation may also be required during calibration.

Can cobalt-based magnetic sensors be used to detect AC magnetic fields?

Yes, cobalt-based magnetic sensors can be used to detect AC magnetic fields, as long as the frequency of the field is within the sensor’s bandwidth. The sensor’s response time and signal conditioning circuitry will determine its ability to accurately measure AC fields.

結論

Cobalt-based magnetic sensors represent a powerful and versatile technology with numerous applications across various industries. Their excellent magnetic properties, combined with ongoing advancements in materials science and manufacturing techniques, ensure their continued importance in the future.

Remember these key takeaways:

- Cobalt’s superior magnetic properties make it ideal for high-performance sensors.

- Design considerations like thin-film structure and alloy selection are crucial.

- Temperature stability is a key performance factor to consider.

- Applications range from automotive and consumer electronics to medical and aerospace.

- Ongoing research and development are continuously improving sensor performance.

Thanks for reading! I hope you found this article helpful! Feel free to reach out if you have any more questions!