Are you facing a magnetic dilemma? Deciding between electromagnets and permanent magnets for your industrial application can feel overwhelming. This article breaks down the critical differences between these two magnetic powerhouses, helping you understand their strengths and weaknesses and ultimately choose the optimal solution for your specific needs. We’ll explore everything from lifting applications and separation processes to advanced technologies like MRI machines and even simple everyday tools. Get ready to demystify the world of magnets and make an informed decision.

What Are Electromagnets and Permanent Magnets, and What’s the Fundamental Difference?

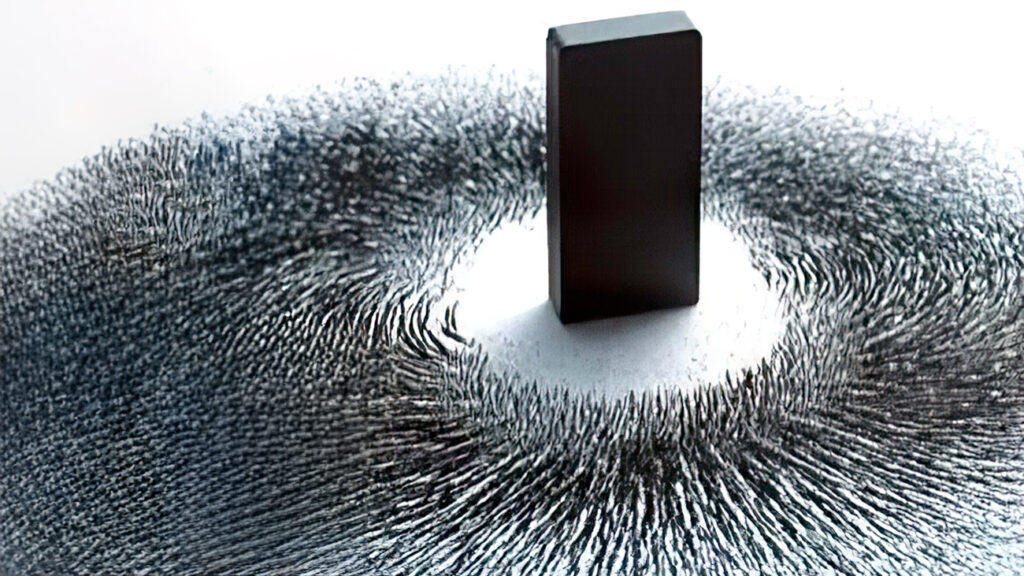

Okay, let’s start with the basics. Both electromagnets and permanent magnets produce magnetic fields, but their core mechanics are completely different.

永久磁石: These are materials, usually alloys of metals like iron, nickel, and cobalt, that have been magnetized and retain their magnetism without needing an external power source. Their atoms are aligned in a way that creates a consistent magnetic field. Think of refrigerator magnets or compass needles.

- Electromagnets: These magnets generate their magnetic field by passing an electric current through a coil of wire. The magnetic field strength is directly related to the amount of current flowing through the coil and the number of turns in the coil. Stop the current, stop the magnetic field.

The key difference? Control. Electromagnets offer on-demand magnetism, adjustable field strength, and the ability to switch polarity, while permanent magnets offer constant magnetism and simplicity.

What Are the Advantages of Using Electromagnets in Industrial Settings?

Electromagnets bring a unique set of strengths to the industrial playing field. Their primary advantage is control. I’ve seen firsthand how this control translated to enormous efficiency gains in numerous applications.

Adjustable Magnetic Force: The power of an electromagnet can be easily adjusted by varying the current. This means you can fine-tune the magnetic force to suit specific tasks.Imagine a robotic arm lifting delicate glass panels versus heavy steel beams—an electromagnet can adapt in ways a permanent magnet simply can’t.

On/Off Functionality: Electromagnets can be turned on and off instantly. This is essential in applications like magnetic separators, where materials need to be released quickly and reliably.

- An example of this would be in recycling plants where electromagnets are used to efficiently separate ferrous metals from other materials like aluminum and plastics.

- Polarity Reversal: Some electromagnets can have their polarity reversed by changing the direction of the current. This allows for applications like levitation and precise positioning.

What Are the Advantages of Using Permanent Magnets in Industrial Applications?

Permanent magnets, despite their limitations in control, provide some invaluable advantages, primarily reliability and simplicity.

No Power Consumption: This is the biggest selling point. They require no electricity to maintain their magnetic field, leading to significant energy savings. I remember a client who switched to permanent magnetic lifters in their warehouse and saw a noticeable drop in their electricity bill.

Constant Magnetic Force: If you need a consistent magnetic field and adjustability is not a concern, permanents are a great option.

Durability:: Permanent magnets are not sensitive to heat like electromagnets which can overheat.

- Simple Design: Permanent magnets are inherently simpler to implement as they don’t require complex wiring, control systems, or power supplies, which reduces the likelihood of a electrical fire.

Electromagnet vs. Permanent Magnet: How Does Strength Compare?

Magnetic strength is a complex topic. While a very large electromagnet can potentially generate a stronger magnetic field than a permanent magnet of the same size, it’s not always the case.

High-Strength Permanent Magnets: Modern permanent magnets, particularly neodymium magnets (often referred to as NdFeB magnets), are incredibly strong for their size. They can generate magnetic fields comparable to, or even stronger than, small to medium-sized electromagnets. Rare earth magnets are by far the strongest available.

Electromagnet Strength Factors: The strength of an electromagnet depends on several factors: the number of turns in the coil, the current flowing through the coil, the core material (usually iron or steel), and the geometry of the magnet.

- The Trade-Off: To achieve extremely high field strengths with electromagnets, you need high current and significant cooling systems to dissipate the heat generated. This increases complexity and cost.

Here’s a table comparing typical strength ranges:

| マグネットタイプ | 相対的な強さ | 備考 |

|---|---|---|

| フェライト(セラミック) | 低い | Common, inexpensive |

| アルニコ | ミディアム | Good temperature stability |

| サマリウムコバルト(SmCo) | 高い | Excellent high-temperature performance |

| ネオジム(NdFeB) | 非常に高い | Strongest available, but sensitive to heat |

| 電磁石 | Variable | Strength depends on current and design |

The reality is that the true "strength" comparison is also dependent on duty cycle. Do you need constant, maximum strength? An appropriately sized neodymium magnet is likely the best solution. Do you need variable strength? Only an electromagnet can provide that.

Which is More Energy Efficient: Electromagnet or Permanent Magnet?

This is where permanent magnets shine.

- Permanent Magnets: Zero Energy Input: Since they maintain their magnetism without electricity, they are inherently energy-efficient for applications requiring constant magnetic force.

- Electromagnets: Energy Consumption: Electromagnets consume energy whenever they are activated. The energy consumption is directly proportional to the current flowing through the coil. However, in some applications, the energy savings from precise control and on-demand operation can outweigh the energy consumption.

I always advise clients to carefully consider their duty cycle. If a magnetic device needs to be "on" 24/7, a permanent magnet is almost always the more energy-efficient choice. However, if it’s only "on" for brief periods, the trade-off for the flexibility of an electromagnet could be worthwhile.

In What Material Handling Applications are Electromagnets Preferred?

Electromagnets are workhorses in material handling because of their adaptability.

Steel Mills and Scrap Yards: Large electromagnets are used to lift and move massive steel plates, beams, and scrap metal. The ability to control the magnetic force is crucial for safely handling these heavy loads.

自動車産業: Used in robotic arms for picking and placing metal components during assembly. The on/off functionality ensures quick and precise movements.

Automated Warehouses: Employed in conveyor systems for sorting and moving packages.

- 磁選機: Used to quickly extract ferrous contaminants from grains, powders, and liquids.

Electromagnets offer exceptional versatility in material handling because they can be controlled precisely and safely. These advantages allow for improvements in productivity and the facilitation of automated manufacturing processes.

Where are Permanent Magnets Better Suited for Material Handling?

While electromagnets excel in applications requiring controlled release, permanent magnets offer advantages in situations demanding simplicity, safety, and consistent holding force.

Magnetic Lifters: Permanent magnet lifters are used to lift steel plates, pipes, and other ferrous materials in warehouses and construction sites. They provide a secure grip without any power requirements. These are typically made with neodymium magnets and a "switch" mechanism that allows the magnetic field to be turned on and off mechanically

Magnetic Separators (Static): Permanent magnets are used in some magnetic separators for continuous removal of ferrous contaminants.

- For example they are used in many food processing plants to avoid metal contamination.

- Magnetic Holding Devices: Used to hold workpieces securely in place during machining or welding operations.

Case Study: Electromagnets in MRI Machines vs. Permanent Magnets

Magnetic Resonance Imaging (MRI) offers a fascinating example of how electromagnets and permanent magnets find distinct applications.

Traditional MRI Machines (Electromagnets): "High-field" MRI systems rely on large, superconducting electromagnets to generate powerful and uniform magnetic fields. These fields are crucial for producing high-resolution images. The ability to precisely control the field is paramount. A typical MRI machine might use a 1.5 Tesla or even 3.0 Tesla magnet—far stronger than what a practical permanent magnet could provide.

- Open MRI Machines (Permanent Magnets): "Low-field" MRI systems sometimes use permanent magnets. These systems offer a more open and less claustrophobic environment for patients. However, the image quality is generally lower compared to high-field systems.

The choice depends on the desired imaging quality and patient comfort. Electromagnets remain the standard for clinical-grade MRI due to their superior field strength and control.

Industrial Costs: Electromagnets vs. Permanent Magnets

Cost is a significant factor in any industrial decision.

Permanent Magnets: Lower Upfront Cost: Generally, permanent magnets have a lower upfront cost, especially for smaller applications.

Electromagnets: Higher Upfront Cost, Potential Savings: Electromagnets require a more complex system: power supply, control circuitry, and often cooling systems. This results in a higher initial investment. However, in applications where precise control and on-demand operation lead to greater efficiency and reduced waste, the long-term cost savings can outweigh the initial expense.

- Consider Lifecycle Costs: Don’t just focus on the initial purchase price. Consider the long-term costs, including energy consumption, maintenance, and potential downtime. A permanent magnet might be cheaper initially, but if it requires frequent replacement or leads to inefficiencies, an electromagnet could be the more cost-effective option in the long run.

Here’s a general comparison:

| ファクター | 永久磁石 | 電磁石 |

|---|---|---|

| Initial Cost | Generally lower | Generally higher |

| エネルギー消費 | Zero | 重要 |

| メンテナンス | 低い | Can be higher |

| Lifespan | Long, but can demagnetize | Long if properly maintained |

| Control | 限定 | 素晴らしい |

| 強さ | Good, but limited by material | Potentially very high, adjustable |

Future Trends: What’s Next for Industrial Magnet Technology?

The future of industrial magnet technology is exciting, with advancements in both electromagnet and permanent magnet design.

- High-Temperature Superconducting Electromagnets: These offer the potential for even stronger magnetic fields with reduced energy consumption.

- Advanced Permanent Magnet Materials: Research continues to improve the strength and temperature stability of permanent magnets, particularly neodymium magnets.

- Smart Magnetic Systems: Integrating sensors and control systems to create "smart" magnets that can adapt to changing conditions and optimize performance.

These innovations promise to further enhance the capabilities of both electromagnets and permanent magnets, opening up new possibilities for industrial applications.

FAQセクション

Here are some frequently asked questions.

What is the main factor determining whether to choose an electromagnet or a permanent magnet?

The main factor is the application’s need for control. If you require adjustable strength, on/off capabilities, or polarity reversal, an electromagnet is the better choice. If you need a constant magnetic field with zero energy input, a permanent magnet is ideal.

Are electromagnets dangerous?

While large industrial electromagnets can generate powerful magnetic fields, they are generally safe when used properly and with appropriate safety measures. Just be sure to keep away from the metal and from anything that can be damaged such as hard drives and electronic equipment.

Can permanent magnets lose their magnetism?

Yes, permanent magnets can lose their magnetism over time due to factors like high temperatures, strong opposing magnetic fields, or physical impact. But it will depend on the surrounding temperature and if there is any exposure to radiation.

Which type of magnet is better for lifting heavy objects?

Both electromagnets and permanent magnets are used for lifting heavy objects. Electromagnets are often preferred for very heavy loads and applications where controlled release is necessary. Permanent magnet lifters are a good option for lighter loads and situations where energy efficiency is important.

Are there hybrid magnetic systems that combine electromagnets and permanent magnets?

Yes, hybrid systems exist. These combine the benefits of both types of magnets. One common design uses permanent magnets to provide a base magnetic field, with an electromagnet used to enhance or control the field.

How do I choose the right electromagnet for my application?

Choosing the right electromagnet involves considering factors like the required magnetic force, the size and shape of the object being lifted or manipulated, the duty cycle, and the operating environment. Consulting with a magnet specialist is a good way to ensure you select the optimal solution.

結論要点

Choosing between electromagnets and permanent magnets is a strategic decision that can significantly impact the efficiency, cost-effectiveness, and overall performance of your industrial operations. Here are the key takeaways to remember:

- Electromagnets offer unparalleled control over magnetic force, including on/off functionality and polarity reversal.

- Permanent magnets excel in energy efficiency, requiring no power to maintain their magnetic field.

- Consider the duty cycle: permanent magnets are ideal for constant operation, while electromagnets are better suited for intermittent use.

- Evaluate the long-term costs: factor in energy consumption, maintenance, and potential downtime when comparing the two options.

- Consult with a magnet specialist for expert guidance in selecting the optimal magnetic solution for your specific application.

By carefully weighing these factors, you can harness the power of magnets to optimize your industrial processes and achieve your business goals.