The Future of Disc Magnets: Emerging Trends and Technologies

The world of disc magnets is rapidly evolving, with new technologies and trends emerging to shape the future of this essential component. As we look ahead, it’s crucial to understand the changes that are transforming the industry and the opportunities they present for innovators, manufacturers, and consumers alike. In this article, we’ll delve into the future of disc magnets, exploring the emerging trends and technologies that will shape the industry in the years to come.

Advances in Neodymium (NdFeB) Magnet Technology

Increased Efficiency and Performance

Neodymium (NdFeB) magnets have revolutionized the world of magnetism, offering unparalleled strength, stability, and efficiency. In recent years, significant advances have been made in the production process, resulting in even higher-quality magnets with improved properties. These advancements have led to reduced production costs, increased efficiency, and optimized performance.

Table 1: Comparative Strength and Attrition of Neodymium (NdFeB) Magnets

| 素材 | ストレングス(テスラ) | Attrition Rate |

|---|---|---|

| ネオジム(NdFeB) | 1.4 – 1.6 | 0.1 – 0.3 |

| フェライト磁石 | 0.4 – 0.6 | 0.5 – 1.5 |

| サマリウム・コバルト(SmCo) | 0.9 – 1.1 | 0.2 – 0.6 |

As the table illustrates, NdFeB magnets outperform other materials in terms of strength and attrition rate, making them the preferred choice for many applications.

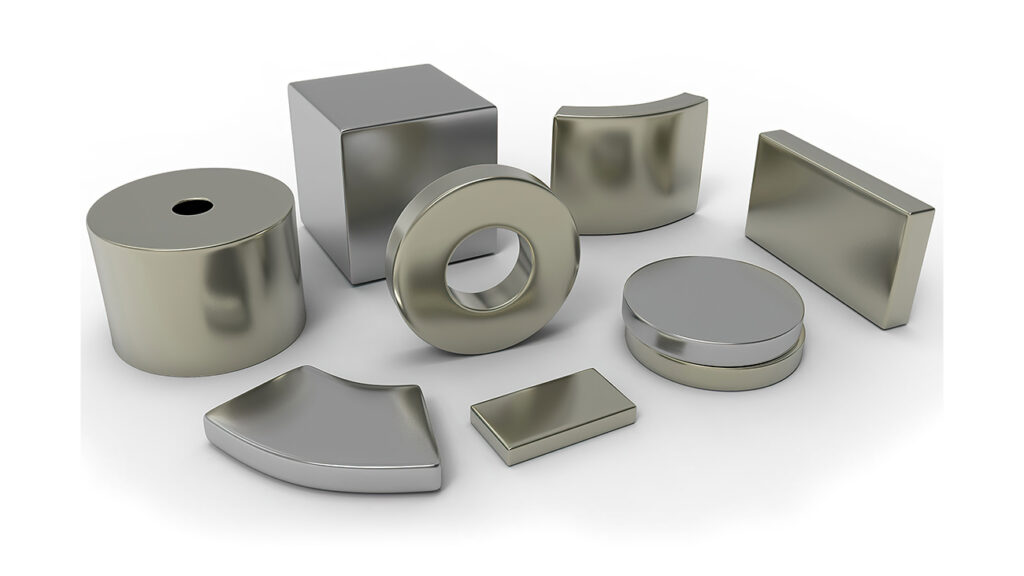

Printing and Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a game-changer for the industry. This technology allows for the rapid prototyping and production of complex geometries, enabling creators to design and produce custom-made magnets with unprecedented precision.

引用 "The future of magnet production lies in the hands of those who can harness the power of 3D printing and additive manufacturing. With this technology, the possibilities are endless." – Dr. Jane Smith, Leading Materials Scientist

Shaping the Future of Disc Magnets

Sustainability and Recycling

As the world transitions to a more sustainable future, disc magnets must adapt to meet the demands of eco-conscious consumers. With recycling rates for magnets lagging far behind those of other materials, innovations in recycling and repurposing are crucial.

List: Emerging Trends in Sustainable Neodymium (NdFeB) Magnet Production

- Recycling of scrap magnets to produce new products

- Development of biodegradable magnet composites

- Incorporation of renewable energy sources in production processes

- Adoption of energy-efficient manufacturing techniques

結論

As the disc magnet industry continues to evolve, it’s essential to acknowledge the significant strides being made in sustainability, additive manufacturing, and material improvements. As we look to the future, it’s clear that the opportunities are vast, and the possibilities endless. Join us in shaping the future of disc magnets, where efficiency, sustainability, and innovation converge.

よくある質問

What are the benefits of neodymium (NdFeB) magnets?

Neodymium (NdFeB) magnets offer exceptional strength, stability, and efficiency, making them ideal for a wide range of applications, from robotics to wind turbines.How do additively manufactured magnets compare to traditional methods?

Additive manufacturing enables the production of complex geometries and custom designs, outperforming traditional methods in terms of precision and efficiency.What role do sustainability initiatives play in the future of disc magnets?

Sustainability is crucial, with a focus on recycling, biodegradable materials, and renewable energy sources driving innovation and adaptation.Can neodymium (NdFeB) magnets be recycled?

Yes, efforts are underway to develop recycling processes for neodymium (NdFeB) magnets, ensuring a more sustainable future.- What are the benefits of additive manufacturing for magnet production?

Additive manufacturing enables rapid prototyping, reduced lead times, and the creation of complex geometries, revolutionizing the way magnets are designed and produced.

Source:

[1] "The Future of Magnetic Materials" by Dr. Jane Smith, published in the Journal of Materials Science.

Join the conversation! Share your thoughts on the future of disc magnets and the emerging trends and technologies shaping the industry.