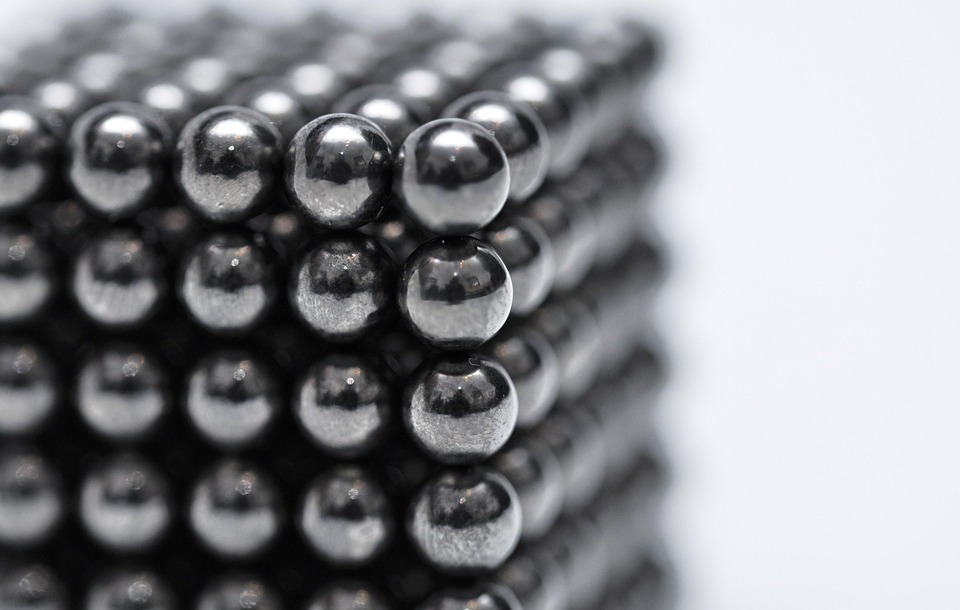

Super magnets, also known as neodymium magnets, are a type of rare earth magnet characterized by their exceptional strength and durability. These magnets are made from an alloy of neodymium, iron, and boron, which gives them their unique properties. They are widely used in various applications, including motors, generators, magnetic separators, and other industrial equipment.

자기 특성 이해

Before selecting a super magnet for your application, it is crucial to understand the key magnetic properties that determine a magnet’s performance. These properties include:

- Magnetic strength: This is the most common parameter used to compare the strength of different magnets. Magnetic strength is typically measured in units of Gauss or Tesla. Super magnets have a high magnetic strength, making them suitable for applications that require a strong magnetic field.

- Magnetic flux density: This refers to the density of the magnetic field lines produced by a magnet. It is usually measured in Gauss or Tesla and is an important factor to consider when selecting a magnet for applications such as magnetic separation or magnetic levitation.

- 강압성: Coercivity is a measure of a magnet’s resistance to demagnetization. It is expressed in units of Oersted (Oe) or Ampere per meter (A/m). Higher coercivity values indicate that a magnet can withstand stronger demagnetizing forces without losing its magnetism.

- 잔존: Remanence, also known as residual magnetism, is the magnetism that remains in a magnet after the external magnetic field is removed. It is typically measured in percentages of the saturation magnetization and is an important factor to consider when choosing a magnet for applications where a stable magnetic field is required.

Factors to Consider When Choosing a Super Magnet

When selecting a super magnet for your application, consider the following factors:

- Application requirements: The first and most important factor to consider is the specific application you are using the magnet for. Different applications have different magnetic requirements, such as the required magnetic strength, field shape, or resistance to demagnetization. Understanding your application’s requirements will help you narrow down the list of suitable magnets.

- Magnet size and shape: Super magnets come in various sizes and shapes, including discs, cylinders, blocks, and customized shapes. The size and shape of the magnet you choose should be appropriate for the intended application and the available space. For example, if you need a magnet to fit into a small space, a small disc or cylinder magnet might be more suitable than a large block magnet.

- Operating environment: The operating environment of the magnet is another crucial factor to consider. Super magnets can be affected by temperature, humidity, and corrosive environments. If your application involves extreme temperatures or harsh environments, choose a magnet with appropriate temperature and corrosion resistance.

- Cost and availability: Budgetary constraints and availability can also influence your magnet selection. Rare earth magnets, including neodymium magnets, can be more expensive than other types of magnets due to their high performance. However, they often provide better value in the long run due to their superior strength and durability. Consider your budget and lead time when selecting a super magnet.

Common Applications of Super Magnets

Super magnets are widely used in various industries and applications, including:

- Motors and generators: Super magnets are commonly used in the construction of motors and generators due to their high magnetic strength and energy efficiency. They can generate strong magnetic fields with smaller magnets, resulting in smaller, lighter, and more efficient motors.

- 자기 분리: The strong magnetic field of super magnets makes them ideal for magnetic separation applications, such as removing ferrous contaminants from non-ferrous materials in recycling and mining industries.

- Magnetic levitation: Super magnets can create strong magnetic fields without consuming much power, making them suitable for magnetic levitation applications, such as maglev trains and levitation systems in manufacturing and research.

- Medical equipment: Super magnets are used in various medical devices, such as magnetic resonance imaging (MRI) machines, which rely on strong magnetic fields to produce detailed images of the human body.

- Aerospace and defense: Super magnets are used in a variety of aerospace and defense applications, including guidance systems, navigation, and communication equipment, due to their high strength, compact size, and resistance to temperature fluctuations.

결론

Choosing the right super magnet for your application requires a thorough understanding of magnetic properties, application requirements, and environmental factors. Super magnets, or neodymium magnets, offer exceptional magnetic strength and durability, making them ideal for a wide range of applications in various industries. By considering factors such as magnetic strength, size and shape, operating environment, and cost, you can select the best super magnet to meet the specific needs of your application.

자주 묻는 질문

1. What is the difference between a super magnet and a neodymium magnet?

There is no significant difference between a super magnet and a neodymium magnet. Super magnet is a colloquial term used to describe neodymium magnets, which are a type of rare earth magnet known for their exceptional strength and durability.

2. How do I know what grade of neodymium magnet I need?

The grade of a neodymium magnet refers to its magnetic strength, which is determined by the composition of the alloy and the manufacturing process. Higher grade magnets have higher magnetic strengths. To determine the appropriate grade for your application, consider factors such as the required magnetic field strength, operating temperature, and the size and shape of the magnet needed.

3. Can super magnets be used in high-temperature environments?

Super magnets, or neodymium magnets, can be used in high-temperature environments up to a certain point. The Curie temperature, which is the point at which a magnet loses its magnetism, varies depending on the alloy composition. For neodymium magnets, this temperature ranges from 310°C (592°F) to 340°C (644°F) depending on the grade. If your application involves temperatures above the Curie temperature, consider using a different type of magnet or implementing cooling measures.

4. Can super magnets be machined or customized?

Yes, super magnets can be machined or customized to meet specific application requirements. However, machining neodymium magnets can be challenging due to their hardness and brittle nature. It is recommended to consult with a professional magnet manufacturer or machining specialist for custom magnet solutions.

5. How do I safely handle and store super magnets?

Super magnets, due to their exceptional magnetic strength, require proper handling and storage precautions to prevent accidents and damage to the magnets. Here are some safety tips:

- Always wear gloves and safety goggles when handling super magnets to protect your skin and eyes from potential injuries.

- Keep magnets at least 10 cm (4 inches) away from electronic devices, pacemakers, and other magnets to avoid unintended attraction or repulsion forces.

- When handling multiple magnets, always use a non-magnetic tool to avoid pinching fingers between attracting magnets.

- Store super magnets in a secure, dry, and stable location, preferably in a non-magnetic container or a container lined with a non-magnetic material to prevent accidental attraction to ferromagnetic objects.