Imagine magnets that aren’t just fridge decorations, but critical components in everything from electric motors to medical devices. Understanding how magnetic fields behave in these magnets, particularly with different shapes, is paramount for optimal design. This article explores Finite Element Analysis (FEA), a powerful simulation technique, used on different magnet geometries to predict magnetic flux density. We’ll see how FEA empowers engineers to optimize magnet designs for efficiency, performance, and reliability. Forget complex equations; we’re diving into a practical guide!

1. What is Finite Element Analysis (FEA) and Why is it Crucial for Magnet Design?

Finite Element Analysis (FEA) is a computational method used to simulate the behavior of physical phenomena, like magnetic fields, in complex geometries. Imagine breaking down a magnet into thousands of tiny pieces (elements) and then calculating the magnetic field in each piece. FEA does exactly that, allowing us to predict the overall magnetic field distribution with high accuracy.

Why is this crucial? Instead of building countless physical prototypes and painstakingly measuring their magnetic fields, we can use FEA to virtually "test" different designs. This saves time, money, and allows for exploring numerous variations and optimizations. FEA lets us see the invisible – the distribution of magnetic flux density inside and outside the magnet, revealing potential weaknesses or areas for improvement. Think of it as a digital magnifying glass for magnetic fields. Statistics show that using FEA in the design process can reduce prototyping costs by up to 40% and time-to-market by 25%.

2. How Does FEA Calculate Magnetic Flux Density?

At its core, FEA solves Maxwell’s equations, the fundamental laws governing electromagnetism, within the defined geometry. The process generally involves these key steps:

- Pre-processing: This includes defining the geometry of the magnet, material properties (like permeability), and boundary conditions (e.g., applied current, external magnetic fields).

- 메시: The geometry is divided into a finite number of elements, forming a mesh. The finer the mesh, the more accurate the results, but also the higher the computational cost.

- 해결: The FEA software solves the governing equations for each element, taking into account the interactions between elements.

- Post-processing: The results, including magnetic flux density, are visualized and analyzed. This can involve creating contour plots, vector fields, and extracting specific values at points of interest.

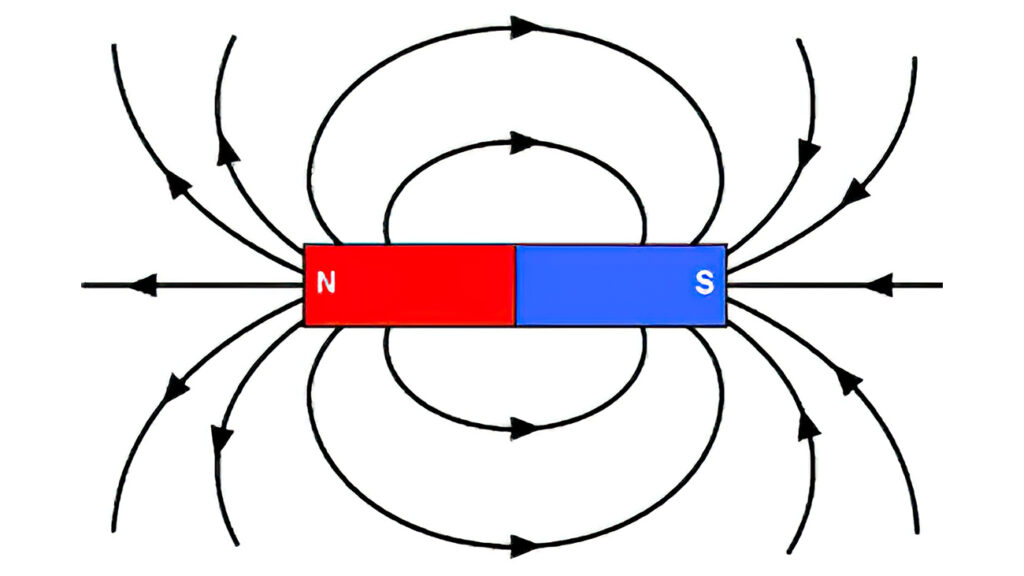

The magnetic flux density (B) is a vector quantity, meaning it has both magnitude and direction. FEA provides a detailed map of this vector field, allowing engineers to understand the strength and orientation of the magnetic field at any point.

3. What Magnet Geometries Benefit Most from FEA?

FEA shines when dealing with complex magnet geometries where analytical solutions are impossible to obtain. Some examples include:

- Arc Magnets: Commonly used in electric motors, their curved shapes pose challenges for calculating magnetic fields analytically.

- FEA allows for optimizing the arc angle and thickness of the magnet to achieve the desired torque and efficiency.

- Rectangular Magnets with Holes: These are often used in sensors and actuators, and the presence of holes significantly alters the magnetic field distribution.

- FEA helps in determining the optimal hole size and location to minimize magnetic field leakage and maximize sensitivity.

- Pot Magnets: These magnets are enclosed in a steel pot, which concentrates the magnetic field and provides shielding.

- FEA allows for analyzing the effect of the pot material and geometry on the magnetic field strength and distribution.

- Complex Assemblies: Motors and generators frequently include very complex geometries. The benefit of FEA in these assemblies are significant.

- Halbach Arrays: Special magnet arrangements designed to concentrate the magnetic field on one side.

- FEA is essential for designing and optimizing Halbach arrays, as the magnetic field distribution is highly dependent on the arrangement and dimensions of the magnets.

4. How Does Magnet Shape Affect Magnetic Flux Density Distribution?

The shape of a magnet has a profound impact on the distribution of magnetic flux density. For example:

- Long, Thin Magnets: Tend to have a more uniform magnetic field along their length, but the field strength drops off rapidly at the ends.

- Short, Thick Magnets: Exhibit a stronger magnetic field near the poles, but the field decays more quickly with distance.

- Sharp Corners: Can concentrate the magnetic field, potentially leading to saturation and demagnetization.

- Halbach Array Examples: Circular Halbach arrays concentrate the magnetic field in the center, while linear arrays concentrate it on one side.

FEA enables us to visualize these effects and quantitatively analyze the magnetic flux density distribution for different shapes. We can observe concentrations, leakage, and uniformity in the magnetic field, factors critical for performance.

5. What Material Properties are Inputted into a Finite Element Analysis of a magnet?

The accuracy of FEA simulations heavily relies on the correct input of material properties. Key magnetic properties include:

- Permeability: A measure of how easily a material allows magnetic flux to pass through it.

*Ferromagnetic materials such as Steel have high permeability. - 리맨언스(Br): The residual magnetization remaining in a material after the magnetizing field is removed.

- 강압성(Hc): The measure of a material’s resistance to becoming demagnetized.

- Demagnetization Curve: A curve representing the relationship between the magnetic field and magnetization in a material. This curve is crucial for predicting the behavior of permanent magnets under varying conditions.

- Electrical Conductivity: Important for transient effects in AC applications.

These parameters inform the FEA software, allowing it to accurately simulate the interaction of the magnetic field with the magnet and surrounding materials.

6. Can FEA Predict Demagnetization Risks in Magnets?

Yes, FEA can be used to predict the risk of demagnetization in magnets. By applying external magnetic fields or temperature variations in the simulation, we can assess the stability of the magnet and identify regions where the magnetic field falls below the coercivity of the material. This is crucial for ensuring the long-term performance and reliability of the magnet.

For example, operating a Halbach Array at high temperatures can significantly increase the risk of demagnetization. FEA allows engineers to understand and mitigate these risks by:

- Optimizing magnet geometry to reduce demagnetizing fields.

- Selecting materials with higher coercivity.

- Implementing cooling strategies to maintain operating temperatures within safe limits.

7. How Do Air Gaps Affect Magnetic Flux Density and How Can FEA Help?

Air gaps, the spaces between magnets and other components, significantly affect the magnetic flux density. Air has a low permeability, which means that magnetic flux lines tend to avoid traveling through air gaps. This results in:

- Reduced Magnetic Field Strength: The magnetic field strength decreases across the air gap.

- Fringing Effects: The magnetic flux lines tend to spread out (fringe) around the edges of the air gap, leading to a non-uniform field distribution.

FEA allows for accurately modeling the air gap and predicting the magnetic flux density distribution within it. By varying the size and shape of the air gap in the simulation, we can optimize the magnetic circuit for maximum performance. Case studies have shown that FEA-optimized air gap designs significantly improve the efficiency of electric motors and generators.

8. What Role Does Mesh Density Play in FEA Accuracy?

Mesh density, the number of elements used to discretize the geometry, plays a critical role in the accuracy of FEA results. A finer mesh (more elements):

- Provides a more accurate representation of the geometry and magnetic field distribution.

- Captures finer details and gradients in the magnetic field.

- Leads to more accurate solutions.

However, a finer mesh also increases the computational cost and simulation time. Therefore, it is important to strike a balance between accuracy and computational efficiency. Adaptive meshing techniques, where the mesh is automatically refined in regions of high gradients or complex geometries, can help to achieve optimal results. A common practice is to perform a mesh convergence study, where the simulation is run with different mesh densities until the results converge to a stable value.

9. What are the Limitations of FEA in Magnetic Field Analysis?

Despite its power, FEA has some limitations:

- Accuracy Depends on Input Data: The accuracy of the results depends heavily on the accuracy of the input data, such as material properties and boundary conditions.

- 계산 비용: Complex geometries and fine meshes can require significant computational resources and time.

- Simplifications: FEA models often involve simplifications of the real-world situation, such as neglecting minor geometric features or assuming ideal material properties.

- 가비지 인, 가비지 아웃: This holds especially true when dealing with material properties that vary with temperature.

It’s important to be aware of these limitations and validate the FEA results with experimental measurements whenever possible. FEA should be seen as a powerful tool, but not a replacement for sound engineering judgment and experimental verification.

10. How Can FEA Optimize Magnet Design for Specific Applications?

FEA is a powerful tool for optimizing magnet design for a wide range of applications. Here are some specific examples:

- 전기 모터: FEA can be used to optimize the shape and arrangement of magnets in electric motors to maximize torque, efficiency, and power density.

- Magnetic Sensors: FEA helps in designing high-sensitivity magnetic sensors by optimizing the magnet geometry and placement to achieve the desired magnetic field distribution.

- 자기공명영상(MRI): FEA is essential for designing MRI magnets that produce a highly uniform and stable magnetic field over a large volume.

- 액추에이터: FEA can optimize force and speed.

Considerations must be made for materials, heating considerations and external elements.

By using FEA to simulate and optimize the magnetic field distribution, engineers can develop innovative and high-performance magnetic devices for a wide range of applications. Case studies have consistently shown that FEA-optimized designs outperform traditional designs in terms of efficiency, performance, and reliability.

FAQ Section: Your Burning Questions Answered

What software is commonly used for FEA of magnetic devices?

Popular FEA software packages for magnetic simulations include ANSYS Maxwell, COMSOL Multiphysics, and Magnet (by Infolytica). Each software has its strengths and weaknesses, and the best choice depends on the specific application and user preferences.

How much does FEA analysis typically cost?

The cost of FEA analysis can vary widely depending on factors such as the complexity of the model, the software used, the computational resources required, and the expertise of the analyst. A simple simulation might cost a few hundred dollars, while a complex simulation could cost thousands or even tens of thousands of dollars. Many universities offer student licenses and discounts.

How do I validate my FEA results?

The best way to validate FEA results is to compare them with experimental measurements. This can involve measuring the magnetic field strength at specific points, measuring the force between magnets, or testing the performance of the magnetic device in a real-world application. Try to correlate with hand calculations.

Can FEA handle temperature-dependent material properties?

Yes, many FEA software packages can handle temperature-dependent material properties. This is important for accurate simulations of magnetic devices that operate at high temperatures, as the magnetic properties of materials can change significantly with temperature. It is critical to ensure that the correct material properties are applied.

What level of experience is required to perform meaningful FEA simulations?

A solid understanding of electromagnetism, numerical methods, and the FEA software is required. While basic simulations can be performed with minimal experience, complex simulations require a deeper understanding of the underlying physics and the limitations of the FEA method.

Conclusion: Mastering Magnetic Fields with FEA

FEA is an indispensable tool for understanding and optimizing magnetic flux density in various magnet geometries. By providing a detailed map of the magnetic field, FEA empowers engineers to design high-performance and reliable magnetic devices for a wide range of applications.

다음은 주요 내용을 요약한 것입니다:

- FEA simulates magnetic fields in complex geometries, saving time and money compared to physical prototyping.

- Magnet shape significantly impacts magnetic flux density distribution, which FEA can visualize.

- Accurate material properties are crucial for reliable FEA results.

- FEA helps predict demagnetization risks and optimize air gap designs.

- Mesh density impacts accuracy; a balance is needed between accuracy and computational cost.

- FEA is a powerful tool for optimizing magnet design in specific applications, such as electric motors and magnetic sensors.

By embracing FEA, engineers can unlock the full potential of magnets and push the boundaries of magnetic technology.