# Reducing Eddy Current Losses in Steel: A Deep Dive into Magnet-Based Solutions

Welcome! If you’re involved in electrical engineering, material science, or anyone dealing with electromagnetic devices, you’ve likely encountered the frustrating problem of eddy current losses in steel. These losses reduce efficiency, generate heat (which can damage equipment), and cost money. This article isn’t just theoretical; it’s a practical guide where I’ll share insights and explored the fascinating ways we can use magnets to *reduce* these parasitic currents. I’ll break down the complex physics into understandable terms, cover various techniques, and offer actionable strategies to tackle this issue head-on. Get ready to not only understand the “what” and “why” but also the “how” of minimizing eddy current losses in steel utilizing the power of magnets.

## What are Eddy Currents and Why Should We Care?

Eddy currents are loops of electric current induced within a conductor (like steel) when the conductor experiences a changing magnetic field. Think of dropping a strong magnet down a copper pipe – the magnet falls much slower than you’d expect due to the eddy currents it induces in the pipe. These currents, while interesting, are a major source of energy loss.

* **The Problem:** Eddy currents dissipate energy as heat (Joule heating) due to the resistance of the steel. This heat reduces efficiency in transformers, motors, inductors, and other electromagnetic devices. In some cases, it can even damage the equipment through overheating.

* **The Cost:** These losses translate into wasted energy, increased operational costs, and potentially shorter equipment lifespans. Reducing these losses can significantly improve efficiency and save money.

* **Example:** In a large transformer, eddy current losses can account for a considerable percentage of the total energy lost. Imagine being able to reclaim a significant portion of that lost energy – that’s the power of understanding and mitigating eddy currents.

## How Do Material Properties Influence Eddy Current Losses?

The intrinsic properties of steel play a substantial role in determining the magnitude of eddy current losses. Understanding these properties is critical to selecting the right material and employing specific mitigation strategies.

* **Conductivity (σ):** Higher conductivity means electrons can move more freely, leading to larger eddy currents. Steels with lower conductivity exhibit fewer losses.

* **Permeability (μ):** Higher permeability concentrates the magnetic field within the material, increasing the induced voltage and therefore, potentially increasing eddy current losses. However, it’s a complex interplay.

* **Thickness (t):** Thinner materials tend to have lower eddy current losses since the circulating current paths are shorter.

* **Lamination:** Introducing thin layers of steel, separated by an insulating material, vastly reduces eddy current losses by interrupting the paths of current flow. This is a cornerstone of core design in transformers and motors.

* **Equation:** The power loss due to eddy currents is roughly proportional to f2B2t2/ρ, where f is frequency, B is magnetic flux density, and ρ is resistivity (inverse of conductivity). This equation illustrates the importantance of each of these properties.

**Table:** Impact of Material Properties on Eddy Current Losses

| Material Property | Impact on Eddy Current Losses |

|——————-|——————————–|

| Conductivity (σ) | Higher σ, Higher Losses |

| Permeability (μ) | Complex; generally, Higher μ, *Potential* for higher losses |

| Thickness (t) | Higher t, Higher Losses |

| Lamination | Reduces Losses |

## Can Static Magnets Really Reduce Eddy Current Losses?

This is where it gets interesting! While it might sound counterintuitive, strategically placed static magnets *can* reduce eddy current losses under certain conditions. The underlying principle involves manipulating the magnetic field distribution.

* **Field Shaping:** Magnets can be used to shape the magnetic field, directing flux away from areas where eddy current losses are most prominent or reducing the overall magnetic field density in specific locations. The goal is to minimize the **dB/dt** (rate of change of magnetic flux density) within the steel, as this directly drives eddy current generation.

* **Homogenizing the Field:** Magnets can create more uniform flux distribution, reducing localized concentrations of flux that often lead to elevated eddy current losses. This is effective when used in conjunction with other methods.

* **Compensation fields:** Magnets can be used to generate an opposing magnetic field that counteracts the primary magnetic field, leading to a reduced net change in magnetic flux density in the core material. This is tricky, but useful if done correctly.

**Key Considerations:** The effectiveness of static magnets heavily depends on the specific application. The geometry of the device, the frequency of the magnetic field, and the magnetic properties of the steel all play crucial roles. Careful design and simulation are essential.

## How Does Frequency Affect the Effectiveness of Magnet-Based Solutions?

The frequency of the alternating magnetic field is a critical factor determining the effectiveness of magnet-based solutions for mitigating eddy current losses.

* **Skin Effect:** At higher frequencies, the skin effect becomes more pronounced. This means that the magnetic field and eddy currents are concentrated near the surface of the conductor. This concentration can sometimes render the benefits of static magnet placement less effective since the field shaping is focused on a much smaller portion of the material.

* **Hysteresis Losses:** At higher frequencies, hysteresis losses also increase. Hysteresis losses occur due to energy expended in cyclically magnetizing and demagnetizing the steel. Magnet-based solutions primarily target eddy current losses, and they may have a minimal impact on hysteresis losses, so this tradeoff must be considered.

* **Resonance:** At very high frequencies, resonance effects can become important. The interaction between the induced eddy currents and the static magnetic field can create resonant frequencies where the eddy current losses are amplified. Analyzing these effects is very complex.

**Important Note:** The design and optimization of magnet-based solutions need to consider the frequency range of operation. Solutions effective at low frequencies may not be suitable for high-frequency applications and vice versa.

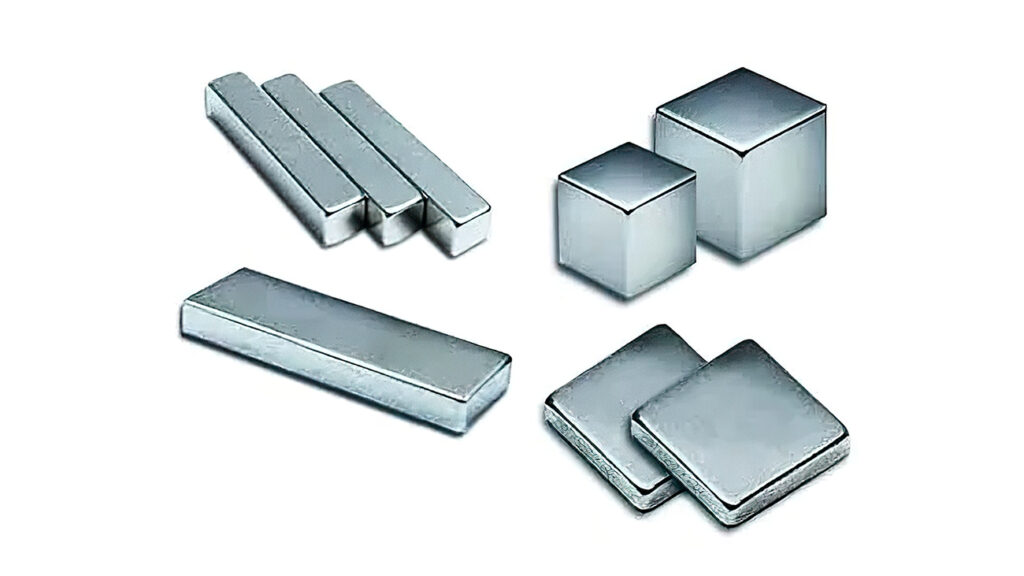

## What are Common Magnet Types Used in Eddy Current Reduction?

Choosing the right magnet is essential for any eddy current reduction strategy. Different magnet types offer varying strengths, temperature stability, and cost-effectiveness.

* **Neodymium Iron Boron (NdFeB):** These are the strongest permanent magnets available, offering excellent field strength for their size. This makes them ideal for applications where space is limited. However, they can be sensitive to high temperatures and corrosion.

* **Samarium Cobalt (SmCo):** SmCo magnets offer superior temperature stability compared to NdFeB magnets. They are also more resistant to corrosion, making them suitable for harsh environments. However, they are generally more expensive and have slightly lower magnetic strength than NdFeB.

* **Ferrite Magnets:** Ferrite magnets are lower in cost and offer good corrosion resistance. However, they have significantly lower magnetic strength compared to NdFeB and SmCo magnets. They are suitable for applications where cost is a primary consideration and high field strength is not required.

* **Alnico Magnets:** Alnico magnets exhibit excellent temperature stability and corrosion resistance. They also have relatively high remanence. However, they are relatively brittle and can be easily demagnetized.

**Table:** Comparison of Common Magnet Types

| Magnet Type | Strength | Temperature Stability | Cost | Corrosion Resistance | Best For… |

|————-|———-|———————|——|———————-|————-|

| NdFeB | Very High | Moderate | High | Moderate | High-performance applications where space is limited |

| SmCo | High | High | Very High | High | Harsh environments and high-temperature applications |

| Ferrite | Low | Moderate | Low | High | Cost-sensitive applications |

| Alnico | Moderate | High | Moderate | High | High temperature environments |

## What Design Considerations are Crucial for Magnet Placement?

Proper magnet placement is *paramount* for achieving effective eddy current reduction. Incorrect placement can even worsen the problem.

* **Simulation:** Employing electromagnetic finite element analysis (FEA) software is essential. This allows you to simulate the magnetic field distribution and optimize magnet placement for maximum eddy current reduction. Tools like ANSYS Maxwell, COMSOL, or similar software are invaluable throughout this process.

* **Optimization Algorithms:** Use optimization algorithms (e.g., genetic algorithms) to automatically determine the optimal location, size, and orientation of the magnets. Manually adjusting magnet placements during the design phase can be very challenging.

* **Iterative Design:** The design process is often iterative. Start with a basic magnet configuration, run simulations, analyze the results, and then refine themagnet placement based on the simulations results. Repeat this process until you achieve the desired level of eddy current reduction.

**Visual Aid (Diagram):** A simple transformer core is sketched to demonstrate where a static magnet could be placed to minimize eddy current losses. Arrows indicate field lines and how the magnet redirects them.

## Can Magnet-Based Solutions be Combined with Traditional Techniques?

Absolutely! Magnet-based solutions are often *most* effective when combined with traditional eddy current reduction techniques.

* **Lamination:** Using laminated steel cores is a fundamental technique. Combine this with magnet placement for synergistic benefits. Lamination reduces the pathways for eddy currents, while properly placed magnets can further shape the magnetic field to minimize the currents.

* **High-Resistivity Steel:** Using steel alloys with higher resistivity (e.g. silicon steel) naturally reduces eddy current losses. Combining this with magnet-based solutions can lead to even greater improvements.

* **Amorphous Metals:** Amorphous metals exhibit very low eddy current losses due to their disordered atomic structure. Magnet-based solutions can be used in conjunction with amorphous metal cores to further optimize efficiency in high-frequency applications.

**Key Advantage:** Combining techniques often leads to a more robust and effective solution than relying on a single technique alone.

## What are the Challenges and Limitations of Using Magnets?

While promising, magnet-based eddy current reduction strategies are not without their challenges.

* **Complexity:** Designing and implementing effective magnet-based solutions can be complex. Accurate simulations and careful optimization are essential.

* **Cost:** High-performance magnets (e.g., NdFeB and SmCo) can be expensive, increasing the overall cost of the solution.

* **Temperature Sensitivity:** Some magnets, such as NdFeB, can be sensitive to high temperatures, potentially reducing their effectiveness over time.

* **Mechanical Integration:** Integrating magnets into existing devices can pose mechanical challenges. The magnets need to be securely mounted and protected from demagnetizing fields.

**Important Note:** Thoroughly evaluate the potential benefits and challenges before employing magnet-based solutions.

## Can You Provide Examples of Successful Applications?

While not yet ubiquitous, magnet-based eddy current reduction is gaining traction in specific applications.

* **High-Frequency Inductors:** In some high-frequency inductor designs, small magnets are used to optimize the magnetic field distribution and reduce eddy current losses in the core material. This is an area where the technology shines, although the solutions tends to be highly custom.

* **Custom Motors:** High-performance motor designs benefit from strategic magnet placement. The magnets help to reduce localized heat buildup from eddy currents.

* **Emerging Applications:** Research is underway to explore the use of magnets for eddy current reduction in transformers, generators, and other electromagnetic devices. This is a developing area with significant potential.

**Case Study:** An example would be a core design that includes an external neodymium magnet that creates a homogenization in the field and is able to reduce the eddy current loss by 10-20% in a given application.

## What Future Innovations are Expected in this Field?

The field of magnet-based eddy current reduction is constantly evolving, with exciting innovations on the horizon.

* **Advanced Magnet Materials:** The development of new magnet materials with higher strength, improved temperature stability, and lower cost will drive wider adoption of magnet-based solutions.

* **Improved Simulation Techniques:** Advancements in FEA software and optimization algorithms will enable more accurate and efficient design of magnet-based solutions. Tools are also starting to enable AI based learning to improve the design.

* **Integration with Additive Manufacturing:** Additive manufacturing (3D printing) opens new possibilities for integrating magnets into complex electromagnetic devices. AM allows for more complex part geometry’s.

* **Active Control:** Research is underway to develop active control systems that dynamically adjust the magnetic field using electromagnets to further reduce eddy current losses.

## FAQ Section: Addressing Your Burning Questions

Here are some common questions about using magnets to reduce eddy current losses.

What is the primary mechanism by which static magnets reduce eddy currents?

Static magnets work by shaping the magnetic field to either reduce the flux density in areas where eddy currents would be high, generate compensating flux, or create a more uniform field over the entire structure. The overarching goal is to minimize d(B)/dt in a localized area leading to a net reduction.

How can I accurately simulate the effect of static magnets on eddy current losses?

Use finite element analysis (FEA) software such as ANSYS Maxwell, COMSOL, or similar tools. Accurately model the geometry, material properties, and boundary conditions to obtain reliable results. Validate your simulations with experimental measurements.

Are there specific geometries or applications where magnets are more effective than others?

Magnets are generally more effective in applications where the magnetic field distribution is non-uniform and concentrated in certain areas. High-frequency inductors and certain motor designs are examples where magnet placement can be beneficial.

What are the consequences of improper magnet placement?

Improper magnet placement can actually *increase* eddy current losses by creating unfavorable field distributions. This is why careful simulation and optimization are essential.

How do temperature variations affect the performance of these magnet-based systems?

The magnetic properties of some magnet materials (e.g., NdFeB) are temperature-dependent. At high temperatures, the magnetic strength can decrease, reducing the effectiveness of the solution. Choose magnets with good temperature stability for high-temperature applications.

Is it possible to retrofit existing equipment with magnets to reduce eddy current losses?

It depends on the design. Retrofitting can be challenging, but in some cases, it may be possible to add magnets to existing equipment to improve some aspects.

## 결론: 주요 요점

* Eddy current losses are a significant source of energy loss in electromagnetic devices.

* Magnet-based solutions can reduce these losses by shaping and manipulating the magnetic field.

* Proper magnet selection, placement, and simulation are crucial for success.

* Combining magnet-based solutions with traditional techniques often yields the best results.

* While challenges exist, ongoing innovations hold promising potential for future applications.

I hope this post has sparked your curiosity and provided some valuable insights into the use of magnets for reducing eddy current losses in steel. With the right knowledge and tools, you can significantly improve the efficiency and performance of your electromagnetic designs.

Reducing Eddy Current Losses in Steel Using Magnets