This article explores how magnetic steel, specifically in the form of magnetic gripping and fixturing systems, is transforming the manufacturing landscape. We’ll delve into the advantages, applications, different types of magnetic solutions, and future trends, demonstrating why this technology is becoming increasingly indispensable for improved efficiency, precision, and safety in various industries. Join me as we uncover how magnetic steel is revolutionizing manufacturing processes.

What are the Advantages of Using Magnetic Gripping and Fixturing?

Magnetic gripping and fixturing offer a compelling suite of advantages compared to traditional mechanical clamping methods. Think about spending less time setting up a machining process, handling materials with increased safety, and reducing the overall cost of production. These are just a few of the benefits that magnetic steel brings to the table.

Let’s look at some specific advantages:

- Faster Setup Times: Magnetic systems allow for quick and easy workpiece positioning, significantly reducing setup times compared to mechanical clamps.

- Improved Accuracy & Precision: Magnetic forces provide uniform clamping pressure, minimizing distortion and ensuring consistent machining results.

- Increased Safety: Magnetic handling systems reduce the risk of dropped workpieces and enhance operator safety.

- Reduced Tool Wear: By minimizing vibrations and ensuring stable workpiece positioning, magnetic fixturing can extend the life of cutting tools.

- Versatility: Magnetic systems can handle a wide range of workpiece sizes and shapes, making them suitable for diverse manufacturing applications.

The inherent flexibility and efficiency of magnetic gripping and fixturing are driving their adoption across a wide range of manufacturing sectors. Forget tedious bolting and adjustments; magnets offer a more streamlined and adaptable solution.

How Does Magnetic Fixturing Improve Manufacturing Efficiency?

Manufacturing efficiency isn’t just about speed; it’s about optimizing every step of the process, from material handling to final assembly. Magnetic fixturing plays a crucial role in achieving this optimization, streamlining workflows, and reducing wasted time and resources. Imagine reducing downtime due to setup changes or minimizing the risk of errors during intricate machining operations.

Consider these factors:

- Reduced Setup Time: The quick connect and disconnect capabilities of magnetic systems significantly reduce setup and changeover times on machining centers, welding stations, and assembly lines.

- Enhanced Material Handling: Magnetic lifting and conveying solutions enable efficient and safe handling of heavy or bulky workpieces, minimizing manual labor and the risk of accidents.

- Optimized Machining Processes: Magnetic fixturing ensures stable and secure workpiece holding during machining, allowing for higher cutting speeds and feed rates without compromising accuracy.

- Improved Workflow Integration: Because of the increased speed and flexibility, manufacturing lines can easily be reconfigured. It makes for a smoother process from creation of design and bringing the idea to reality.

By implementing magnetic fixturing, manufacturers can achieve substantial improvements in overall efficiency, translating to higher throughput, lower costs, and increased profitability. It’s about working smarter, not harder, and magnetic technology provides the tools to do just that.

What are the Different Types of Magnetic Gripping Systems Available?

The world of magnetic gripping systems is diverse, with options tailored to various applications and industries. It’s not a one-size-fits-all scenario; selecting the right type of system is crucial for maximizing performance and efficiency. Let’s look at some common types:

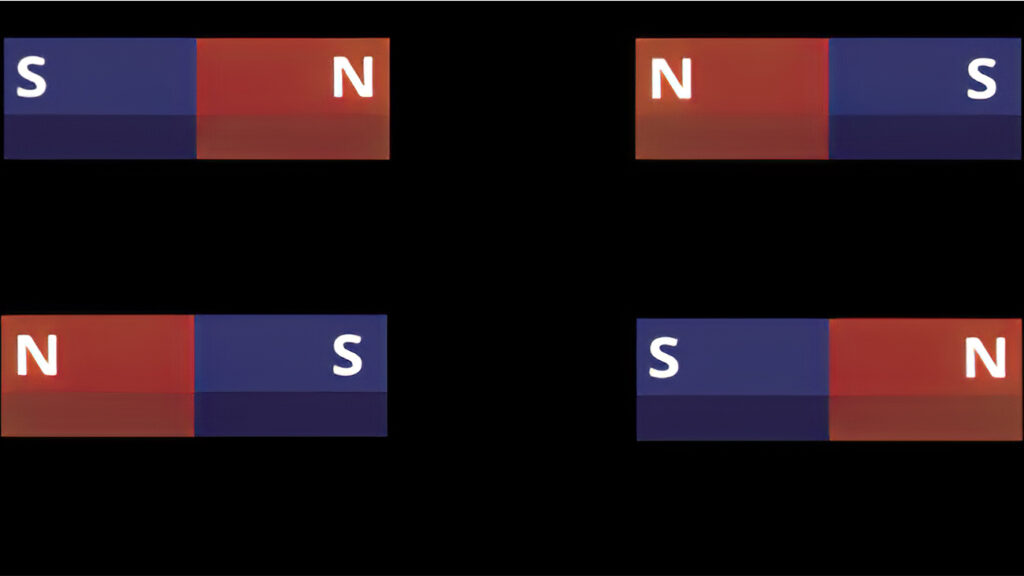

- Permanent Magnets: These systems offer robust, reliable holding power without the need for electrical power. They’re often used in applications where portability and energy efficiency are key.

- Electromagnets: Electromagnets provide adjustable holding force and can be switched on and off as needed, making them suitable for automated processes and applications that require precise control.

- Electro-Permanent Magnets: Combining the best of both worlds, electro-permanent magnets offer the holding power of permanent magnets with the switchability of electromagnets. They’re energy-efficient and ideal for critical applications requiring fail-safe operation.

- Pneumatic Magnetic Grippers: These grippers use compressed air to actuate the magnetic force, providing a simple and cost-effective solution for pick-and-place applications. We see these used often in robot arms.

Choosing the optimal magnetic gripping system depends on factors like workpiece material, size, shape, weight, and the specific requirements of the manufacturing process. Careful consideration of these factors ensures the best possible performance and return on investment.

Table: Comparison of Magnetic Gripping Systems

| System Type | Advantages | Disadvantages | Applications |

|---|---|---|---|

| Permanent Magnets | No power required, cost-effective, portable | Fixed holding force, manually operated | Welding, lifting, fixturing of simple shapes |

| Electromagnets | Adjustable holding force, remote control, automated | Requires continuous power supply, potential for heat build-up | Pick-and-place, automated assembly, scrap handling |

| Electro-Permanent | Energy-efficient, switchable, fail-safe | Higher initial cost, more complex control system | High-precision machining, critical lifting applications, automated welding |

| Pneumatic Magnetic | Simple design, cost-effective, fast actuation | Lower holding force compared to other systems, requires air supply | Pick-and-place of small parts, robotic assembly |

Which Industries Benefit the Most from Magnetic Fixturing?

The benefits of magnetic fixturing extend across a wide range of industries, but some sectors stand to gain more than others. Where do we see the most significant impact? Think about industries that deal with heavy metal, intricate machining or automating processes.

Here’s a look at some key industries:

- Automotive: Magnetic fixturing is widely used for welding, assembly, and machining of automotive components, improving efficiency and accuracy.

- Aerospace: The aerospace industry relies on magnetic systems for handling large, complex parts with precision and minimizing distortion during manufacturing.

- Metalworking: Magnetic gripping and lifting solutions are essential tools for metal fabricators, enabling safe and efficient handling of steel plates, pipes, and other metal materials.

- Manufacturing: Magnetic fixturing is used in machining centers for holding components firmly in place.

- Robotics: Integrated magnetic grippers make production lines efficient.

These are just a few examples, but the applications of magnetic fixturing are constantly expanding as manufacturers seek innovative ways to optimize their processes and gain a competitive edge.

How Does Magnetic Steel Contribute to Safer Work Environments?

Safety is paramount in any manufacturing environment, and magnetic steel technology contributes significantly to creating safer workplaces. By reducing manual handling, minimizing the risk of accidents, and improving overall control over materials, magnetic systems help protect workers and prevent injuries.

Consider these safety enhancements:

- Reduced Manual Handling: Magnetic lifting and conveying systems minimize the need for manual lifting and carrying of heavy or awkward workpieces, reducing the risk of back injuries and other musculoskeletal disorders.

- Improved Workpiece Control: Magnetic fixturing ensures secure and stable holding of workpieces during machining or welding, preventing accidental movement or dropping of parts.

- Enhanced Operator Safety: By minimizing the risk of accidents and improving overall control over materials, magnetic systems create a safer and more comfortable working environment for operators.

- Automated Material Handling: Integrated magnetics in robotic material handling systems prevents the need for people to constantly be next to dangerous machinery.

Investing in magnetic steel technology is not just about improving efficiency and productivity; it’s also about prioritizing the safety and well-being of your workforce. A safer work environment translates to higher morale, reduced absenteeism, and improved overall performance.

Statistic: According to the National Safety Council, lifting, pushing, and carrying are leading causes of workplace injuries. Implementing magnetic lifting systems can significantly reduce these injuries.

What Are the Key Considerations When Selecting a Magnetic Fixturing System?

Choosing the right magnetic fixturing system involves careful consideration of several key factors. It’s not just about picking the most powerful magnet; it’s about selecting a system that is perfectly suited to your specific needs and requirements.

Here’s a checklist of essential considerations:

- Workpiece Material: The type of material being handled or machined will influence the choice of magnetic system. Ferromagnetic materials like steel are ideal for magnetic gripping, while non-ferrous materials may require specialized solutions.

- Workpiece Size and Shape: The size and shape of the workpiece will determine the size and configuration of the magnetic fixture. Complex shapes may require custom-designed solutions.

- Holding Force Requirements: The required holding force will depend on the weight of the workpiece and the forces involved in the manufacturing process. Proper calculations are essential to ensure adequate holding power.

- Automation Requirements: If the process is automated, the magnetic system must be compatible with automation equipment and control systems.

- Budget: The cost of magnetic fixturing systems can vary widely depending on the type, size, and complexity. It’s important to consider your budget and choose a system that offers the best value for your money.

By carefully considering these factors, you can select a magnetic fixturing system that meets your specific needs and delivers optimal performance, efficiency, and safety.

How Does Magnetic Fixturing Compare to Traditional Clamping Methods?

Traditional clamping methods, such as mechanical clamps and vises, have been the mainstay of manufacturing for decades. However, magnetic fixturing offers several distinct advantages over these conventional approaches. Let’s compare the two:

| Feature | Traditional Clamping | Magnetic Fixturing |

|---|---|---|

| Setup Time | Longer, requires adjustments | Faster, quick positioning |

| Clamping Pressure | Uneven, can cause distortion | Uniform, minimizes distortion |

| Workpiece Access | Limited by clamp placement | Unobstructed, full access |

| Versatility | Limited to specific shapes/sizes | Handles diverse shapes and sizes |

| Vibration Dampening | Less effective | Superior, reduces tool wear |

| Safety | Potential for slippage | More secure, reduces accidents |

| Automation | Difficult to automate | Easily integrated into automation |

While traditional clamping methods still have their place in certain applications, magnetic fixturing offers a superior solution for many modern manufacturing processes. Consider a complex shape; a traditional clamp may not be suited for this type of material. The increased efficiency, precision, and safety make it an increasingly attractive option for manufacturers looking to optimize their operations.

What are the Future Trends in Magnetic Steel for Manufacturing?

The field of magnetic steel technology is constantly evolving, with new innovations and applications emerging all the time. What can we expect to see in the future? Let’s explore some exciting trends:

- Smarter Magnetic Systems: Integration with sensors, data analytics, and artificial intelligence will enable magnetic systems to adapt to changing conditions, optimize performance, and predict maintenance needs.

- Advanced Materials: The development of new magnetic materials with higher strength, temperature resistance, and corrosion resistance will expand the range of applications for magnetic steel.

- Customized Solutions: Manufacturers will increasingly demand tailored magnetic solutions designed to meet their specific needs and challenges.

- Wireless Control: This makes it much easier to move and reconfigure production lines.

- Integration with Robotics: Seamless integration with robotic systems will drive further automation and efficiency gains in manufacturing processes.

These future trends point to a continued expansion of magnetic steel technology in manufacturing, with the potential to revolutionize how products are designed, manufactured, and delivered.

Diagram: A visual representation of how AI might manage future magnetic clamping systems through sensor data and process optimization, showing reduced setup times and increased precision.

What Return on Investment Can I Expect From Magnetic Fixturing?

Investing in magnetic steel technology can provide a significant return on investment (ROI) for manufacturers. While the initial cost may seem higher than traditional clamping methods, the long-term benefits can outweigh the upfront investment.

Here’s a breakdown of potential ROI factors:

- Reduced Labor Costs: Faster setup times and automated material handling reduce the need for manual labor, leading to lower labor costs.

- Increased Productivity: Improved efficiency and optimized machining processes result in higher throughput and increased productivity.

- Reduced Tooling Costs: Enhanced vibration dampening extends the life of cutting tools, reducing tooling costs.

- Improved Quality: Uniform clamping pressure and minimized distortion lead to higher-quality products and reduced scrap rates.

- Enhanced Safety: Fewer accidents and injuries result in lower insurance premiums and workers’ compensation costs.

Case Study: A metal fabrication company implemented magnetic lifting systems and magnetic fixturing on its machining line. Reduced labor costs, and increased productivity resulted in an ROI of approximately 18 months.

While the exact ROI will vary depending on the specific application and industry, magnetic fixturing offers a compelling value proposition for manufacturers looking to improve their bottom line.

FAQ Section

What types of materials can be used with magnetic fixturing?

Magnetic fixturing primarily works with ferromagnetic materials like steel and iron. However, specialized systems can be used with non-ferrous materials using innovative techniques such as vacuum or mechanical assistance combined with magnetic force.

Are magnetic systems safe to use around sensitive electronic equipment?

While strong magnets can potentially affect sensitive electronic equipment, modern magnetic systems are often shielded to minimize electromagnetic interference. It’s always recommended to consult with the manufacturer to ensure compatibility with specific equipment.

How do I choose the right magnetic holding force for my application?

The required holding force depends on the weight of the workpiece, the forces involved in the manufacturing process (e.g., cutting forces, acceleration), and the safety factor. Use safety factors when working with materials that can be dangerous.

Can magnetic fixturing be used with CNC machines?

Yes, magnetic fixturing is widely used with CNC machines. Electro-permanent magnets are particularly well-suited for CNC applications due to their ability to be switched on and off electronically and their energy-efficient operation.

How do I maintain my magnetic fixturing system?

Regular cleaning to remove debris is essential. Beyond that, checking for wear or damage, and following the manufacturer’s recommendations for lubrication and inspection. Periodic testing of the holding force is also recommended to ensure continued performance.

Are there magnetic steel solutions for handling non-flat, complex shapes?

Yes, specially designed magnetic fixtures with contoured surfaces or flexible pole configurations can be used to handle non-flat and complex shapes effectively. As well as fixtures that can be custom-manufactured for the end user.

Conclusion

Magnetic steel: Revolutionizing manufacturing through magnetic gripping and fixturing offers a powerful toolkit for manufacturers seeking to improve efficiency, precision, and safety. From faster setup times to enhanced material handling and improved worker safety, magnetic systems are transforming how products are made. Here are the key takeaways:

- Magnetic gripping and fixturing offer significant advantages over traditional clamping methods, including reduced setup times, improved accuracy, and increased safety.

- Different types of magnetic gripping systems are available to suit various applications.

- Industries such as automotive, aerospace, and metalworking benefit greatly from magnetic fixturing.

- Magnetic Steel contributes to a safer work environment by reducing manual handling and improving workpiece control.

- Careful consideration of workpiece material, size, shape, and holding force requirements is essential when selecting a magnetic fixturing system.

- Future trends in magnetic steel include smarter systems, advanced materials, and seamless integration with robotics.

By embracing magnetic steel technology, manufacturers can unlock new levels of performance, productivity, and profitability, paving the way for a more efficient and competitive future.