# Magnetizing Steel: Unveiling Methods, Exploring Applications, and Understanding Key Considerations

Have you ever wondered how a simple piece of steel can become a powerful magnet? This article will take you on a journey to explore the fascinating world of magnetizing steel. We’ll delve into the various methods used to induce magnetism, uncover the diverse applications where magnetized steel plays a crucial role, and discuss the important considerations involved in the process. Get ready to understand the science behind creating magnets and how they impact our daily lives! This is a deep dive, yet explained simply so everyone can understand.

## What Does It Mean to Magnetize Steel, and Why Is It Important?

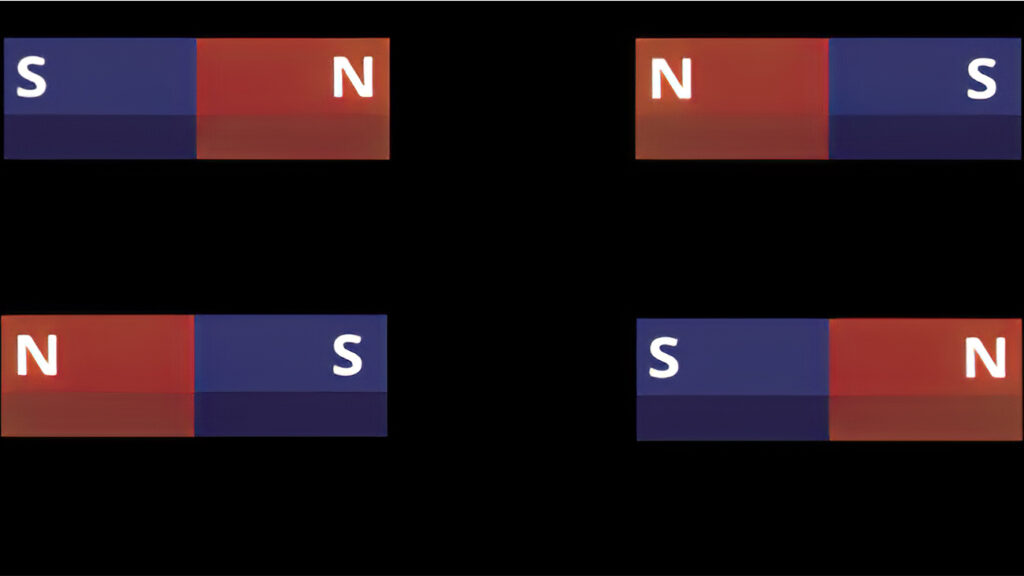

Magnetizing steel, at its core, is about aligning the magnetic domains within the steel’s structure. Steel, in its natural state, often has these tiny magnetic regions pointing in random directions, cancelling each other out. By applying an external magnetic field, we can force these domains to align, resulting in a net magnetic field and turning the steel into a magnet. But why is this important? Think about electric motors, generators, magnetic data storage, and even the simple magnets that hold papers to your refrigerator. The ability to control magnetism in steel allows us to build countless devices that power and enhance our world.

## What Are the Different Methods for Magnetizing Steel?

There are several techniques to magnetize steel, each with its own advantages and limitations. Understanding these methods is key to choosing the right approach for a specific application. The most common methods include:

* **Direct Current (DC) Magnetization:** This involves passing a direct current through a coil wrapped around the steel object. The resulting magnetic field aligns the domains. The strength of the magnetic field produced is directly proportional to the current flowing through the coil and the number of turns in the coil. This is a reliable and controllable method, often used for creating permanent magnets.

* **Alternating Current (AC) Magnetization:** While AC current can magnetize steel, it’s more commonly used for *demagnetizing* it. However, a specific process called *peak magnetization* uses AC with a gradually decreasing amplitude. This allows for a more uniform magnetization.

* **Capacitor Discharge:** Here, a capacitor is charged to a high voltage and then discharged through a coil surrounding the steel. The rapid discharge creates a strong, brief magnetic field used for quickly magnetizing or demagnetizing steel components. It is often used in industrial settings where speed is crucial.

* **Stroke Magnetizing (for permanent magnets):** This method involves repeatedly stroking the steel with a strong permanent magnet in one direction. This slowly aligns the magnetic domains. While simple and requiring minimal equipment, the resulting magnetization is generally weaker compared to other methods.

Which method is best will depend largely on the material, the desired magnetic strength, and the specific application.

## How Does Material Composition Affect the Magnetization Process?

The type of steel significantly impacts how easily it can be magnetized and the strength of the resulting magnet. Certain alloys are designed to be permanently magnetized, while others are better suited for temporary magnetization.

* **Hard Steels:** These steels, like carbon steel with added alloys such as tungsten or chromium, are difficult to magnetize but retain their magnetism for a long time, making them ideal for permanent magnets. Their high coercivity (resistance to demagnetization) is the key factor.

* **Soft Steels:** Conversely, soft steels, like iron and low-carbon steel, are easily magnetized and demagnetized. They’re perfect for applications requiring temporary magnetism, such as electromagnets. They have low coercivity.

* **Specialty Alloys:** Alloys like Alnico (Aluminum, Nickel, and Cobalt) and rare-earth magnets (like Neodymium and Samarium Cobalt) offer exceptional magnetic properties. Alnico magnets offer good temperature stability, while rare-earth magnets boast extremely high magnetic strength. The selection process should involve a careful analysis of the needs of your specific task.

The microstructure, grain size, and presence of impurities also influence the process. Homogeneous and fine-grained structures facilitate easier domain alignment.

## What Are Some Common Applications of Magnetized Steel?

Magnetized steel plays a vital role in a wide array of applications, showcasing its versatility and importance in various industries. Here are a few examples:

* **Electric Motors and Generators:** Magnets are integral components in electric motors, converting electrical energy into mechanical energy, and in generators, converting mechanical energy into electrical energy. Steel magnets, often in the form of permanent magnets or electromagnets, generate the magnetic fields required for this energy conversion.

* **Data Storage:** Hard drives utilize magnetic materials deposited on spinning platters to store information. The data is encoded by magnetizing small areas of the disk in different directions. The read/write head uses magnetic fields to access and modify this data.

* **Magnetic Separators:** Industries use magnetic separators to remove ferrous contaminants from materials. Powerful magnets attract and hold iron particles, isolating them from other materials in various processes like recycling, mining, and food processing.

* **Medical Imaging (MRI):** Magnetic Resonance Imaging (MRI) machines rely on extremely strong magnetic fields to produce detailed images of the human body. These fields, generated by large superconducting magnets, interact with hydrogen atoms in the body, allowing doctors to visualize internal organs and tissues.

* **Speakers and Headphones:** Speakers use magnets to convert electrical signals into sound waves. A coil of wire (voice coil) attached to a diaphragm is placed within the field of a permanent magnet. When an electrical signal passes through the coil, it creates a magnetic field that interacts with the permanent magnet, causing the diaphragm to vibrate, producing sound.

* **Door Latches and Closure Systems** Small electromagnets or permanent magnets can be used to keep doors closed firmly, or to secure latches. These are used in both commercial and residential settings.

This table provides a quick overview:

| Application | Description | Type of Magnet |

| ————————— | ——————————————————————————- | ————- |

| Electric Motors | Converts electrical energy into mechanical energy | Permanent/Electromagnets |

| Data Storage | Stores digital information on hard drives | Magnetic Film |

| Magnetic Separators | Removes ferrous contaminants from materials | Permanent Magnets |

| Medical Imaging (MRI) | Produces detailed images of the body | Superconducting Magnets |

| Speakers and Headphones | Converts electrical signals into sound waves | Permanent Magnets |

| Door Latches/Closure Systems| Secures doors and latches | Permanent/Electromagnets |

## What Are the Key Considerations When Designing a Magnetization Process?

Designing an effective magnetization process involves careful consideration of several factors to achieve the desired outcomes.

* **Steel Grade Selection:** As discussed earlier, choosing the right type of steel is paramount. Consider the required coercivity, remanence (residual magnetism), and permeability. Analyze the trade-offs between different alloys based on the application’s specific requirements.

* **Magnetic Field Strength:** This depends on the steel material and the desired level of magnetization. Too weak and the steel won’t fully magnetize, and too strong it is likely to cause domain reversal.

* **Magnetizing Fixture Design:** The fixture, often a coil, needs to create a uniform magnetic field around the steel component being magnetized. Factors to think about are the coil’s shape, size, number of turns, and positioning relative to the steel being magnetized.

* **Temperature Sensitivity:** Magnetic properties are temperature-dependent. High temperatures can demagnetize some materials. Consider the operating temperature range of the application and select steel and magnetization processes accordingly.

* **Demagnetization Risk:** External magnetic fields, mechanical stress, and temperature fluctuations can demagnetize steel over time. Implementing protective measures, such as shielding or stabilizing heat treatments, can help prevent this. Understanding demagnetization curves is important for long-term performance.

## How Can We Measure the Strength of a Magnetized Steel Object?

Measuring the strength of a magnetized steel object is crucial for understanding its performance and ensuring it meets specifications. Several methods are available to quantify magnetic strength:

* **Gaussmeters and Teslameters:** These devices measure the magnetic field strength (magnetic flux density) at a specific point near the magnet. Gaussmeters typically measure in Gauss (G), while Teslameters measure in Tesla (T) – (1 Tesla = 10,000 Gauss). They use a Hall effect sensor that produces a voltage proportional to the magnetic field strength.

* **Fluxmeters:** These instruments measure the magnetic flux (the total magnetic field passing through a surface) of a magnet. They employ a search coil connected to an integrator. When the magnetic flux through the coil changes, a voltage is induced, which is then integrated to determine the total flux.

* **Pull Testers:** These testers are use to measure the force required to pull a magnet away from a steel plate. They give a direct indication of the magnet’s holding power.

* **BH Loop Tracers (Hysteresisgraphs):** BH Loop Tracers are advanced instruments used to characterize the complete magnetic behavior of a material. These machines trace the hysteresis loop (B-H curve), providing information about remanence, coercivity, saturation magnetization, and permeability. This helps engineers precisely define the magnetic properties of their equipment.

Statistics for the precision of each of the above methods vary widely depending on the hardware employed.

## What is Demagnetization, and How Can It Be Prevented?

Demagnetization is the loss of magnetism in a material. It can occur due to various factors, including:

* **High Temperatures:** As previously mentioned, heat can disrupt the alignment of magnetic domains, leading to partial or complete demagnetization. The Curie temperature is the point at which a ferromagnetic material completely loses its magnetism.

* **External Magnetic Fields:** Exposure to strong opposing magnetic fields can force the domains to reorient, reducing the overall magnetization. Intentional demagnetization uses this principle.

* **Mechanical Shock or Vibration:** These can also cause the domains to misalign. Severe impacts or continuous vibrations can gradually weaken a magnet over time.

* **Aging:** Over extended periods, some magnets can experience a gradual decline in magnetic strength because the magnetic domains can settle into a lower energy state.

To prevent demagnetization:

* **Select Materials with High Coercivity:** Choose steels with high coercivity, which are more resistant to demagnetization.

* **Shield Magnets:** Enclose magnets in materials that can shield them from external magnetic fields.

* **Avoid High Temperatures:** Keep magnets below their Curie temperature.

* **Stabilize Heat Treatments:** Subject magnets to stabilizing heat treatments that increase their resistance to temperature and mechanical stress.

* **Proper Storage:** Store magnets in a way that they are not exposed to strong opposing magnetic fields or mechanical stress.

Here’s a diagram illustrating how heat affects the magnetic domains:

[Diagram showing magnetic domains aligned at room temperature and then randomly oriented at high temperature]

Unfortunately, I cannot display a diagram here. However, imagine two squares side-by-side. The first shows the magnetic domain all as arrows facing upwards, and the second one shows them as arrows facing in random directions.

## Can Steel Be Re-magnetized After Being Demagnetized?

Yes, steel can often be re-magnetized after being demagnetized. The process involves reapplying a strong magnetic field to realign the magnetic domains within the steel. The success of re-magnetization depends on several factors:

* **Degree of Demagnetization:** If the steel has been completely demagnetized, it will require a stronger magnetic field to re-magnetize it effectively.

* **Original Magnetization Method:** The optimal re-magnetization method may depend on the original magnetization technique. For instance, a steel magnet initially magnetized by direct current (DC) may require a DC-based re-magnetization process.

* **Steel Grade:** Soft steels, which are easily magnetized and demagnetized, can be re-magnetized more easily than hard steels. Hard steels require stronger magnetic fields to re-align the domains.

* **Heating and Cooling:** In some of the specific methods, heating the steel to a specific temperature and cooling it in the presence of a magnetic field may enhance the re-magnetization process.

* **Presence of Demagnetizing Fields:** It is crucial to apply a magnetic field that overpowers any already existent demagnetizing fields.

For best results, seek advice from an industrial partner.

## Are There Safety Precautions to Consider When Working with Strong Magnets?

Working with strong magnets, especially those used in industrial magnetization applications, can pose several safety risks. Awareness and implementation of safety precautions are essential to prevent accidents and injuries:

* **Pinch Points:** Strong magnets can attract each other with tremendous force, creating pinch points that can cause serious injuries to fingers and hands. Keep fingers and other body parts away from the contact surfaces of strong magnets.

* **Projectile Hazards:** Strong magnetic fields can attract ferromagnetic objects, turning them into projectiles. Clear the work area of loose metal objects that could become airborne.

* **Pacemakers and Medical Implants:** Strong magnetic fields can affect the operation of pacemakers and other medical implants. People with such devices should maintain a safe distance from strong magnets and magnetic fields.

* **Data Storage Devices:** Strong magnetic fields can erase data from magnetic storage devices such as credit cards, hard drives, and flash drives. Keep these devices away from strong magnets.

* **Heavy Lifting:** Large magnets can be very heavy. Use appropriate lifting equipment, such as cranes and hoists, to move them safely.

* **Emergency Procedures:** Establish clear emergency procedures in case of accidents involving magnets. Ensure that personnel are trained in these procedures.

## Where Can I Learn More About Magnetic Materials and Magnetization Techniques?

Expanding your knowledge of magnetic materials and magnetization techniques can open new avenues for innovation and problem-solving. Consider these resources:

* **University Courses:** Many universities offer courses in materials science, electrical engineering, and physics that cover magnetic materials and their applications.

* **Online Courses:** Platforms like Coursera, edX, and Udemy offer a wide range of online courses on magnetism, electromagnetism, and materials science.

* **Professional Societies:** Organizations such as the IEEE Magnetics Society and the Magnetics Society of Japan host conferences, publish journals, and offer educational resources on magnetic materials and magnetization.

* **Industry Conferences and Trade Shows:** These events provide opportunities to learn about the latest advances in magnetic materials and magnetization technologies and network with experts in the field.

* **Scientific Journals:** Publications such as the Journal of Magnetism and Magnetic Materials, IEEE Transactions on Magnetics, and Applied Physics Letters contain cutting-edge research on magnetic materials and magnetization techniques.

* **Books:** Numerous books cover the fundamentals of magnetism and magnetic materials. Look for texts written by reputable authors from respected universities.

* **Manufacturer Websites** Many manufacturers of magnets display detailed case studies or white papers to demonstrate how their products are used in particular applications.

## FAQs About Magnetizing Steel

* **Is it possible to permanently demagnetize a steel magnet?**

Yes, it is possible, but it requires exceeding the material's coercivity through strong opposing fields, high temperatures (approaching or exceeding the Curie temperature), or severe mechanical stress. The ease of permanent demagnetization depends on the coercivity of the specific steel alloy.

* **Can I magnetize stainless steel?**

It depends on the specific grade of stainless steel. Austenitic stainless steels are generally non-magnetic, while ferritic and martensitic stainless steels can be magnetized due to their crystalline structure.

* **How does temperature affect the strength of a magnet?**

Generally, increasing temperature reduces the strength of a magnet. At the Curie temperature, the material will lose its ferromagnetic properties and become paramagnetic.

* **Are electromagnets stronger than permanent magnets?**

Electromagnets can achieve much higher magnetic field strengths than most permanent magnets, but they require a continuous electrical current to maintain their magnetism. Permanent magnets retain their magnetism without external power.

* **What's the difference between magnetic flux density and magnetic field strength?**

Magnetic flux density (B) measures the amount of magnetic flux passing through a given area. In other words, its a measure of magnetic field strength within an object. Magnetic field strength (H) is the measure of an externally applied magnetic field. They are related by the material's permeability.

* **Can magnetization affect the other properties of the steel?**

Magnetization can influence other properties, such as mechanical fatigue resistance. The process can induce stress within the material, but this is typically minimal.

* **How can I dispose of an old magnet safely?**

Magnets do not pose a significant environmental hazard. However, if they are strong, careful handling is advised. Disposal can be done with standard municipal waste, but consider donating them if they are still functional or of significant size.

## Conclusion: Key Takeaways About Magnetizing Steel

* Magnetizing steel involves aligning magnetic domains within its structure, making it essential for countless applications.

* Various methods exist for magnetizing steel, including DC magnetization, AC magnetization, and capacitor discharge, each with its strengths and weaknesses.

* The type of steel significantly influences the magnetization process and the resulting magnetic properties. Hard steels are good for permanent magnets, while soft steels are good for temporary magnets.

* Magnetized steel is essential in electric motors, generators, data storage devices, medical imaging, and many other technologies.

* Designing a successful magnetization process requires careful consideration of the steel grade, magnetic field strength, fixture design, temperature sensitivity, and demagnetization risks.

* Demagnetization can occur due to high temperatures, external magnetic fields, and mechanical stress. Taking preventive measures is critical for maintaining magnet strength.

* Steel can often be re-magnetized after being demagnetized, but the process's success depends on numerous variables.

* Safety precautions are essential when working with strong magnets to prevent injuries and accidents.

* Numerous resources are available for further education on magnetic materials and magnetization techniques.

Understanding the science behind magnetizing steel opens doors to numerous possibilities. By grasping the concepts discussed in this article, you can appreciate the role of magnetized steel in our world and potentially contribute to advancements in magnetic technologies.