Hi, I’m thrilled to delve into the fascinating world of ring magnets and their crucial role in robotics. This article will explore how these simple yet powerful components are driving innovation across various robotic applications, from precise actuators to complex sensor systems. Whether you’re a seasoned engineer, a robotics enthusiast, or just curious about the technology behind our modern machines, this deep dive will offer valuable insights and spark your imagination. Let’s get started!

Why are Ring Magnets Essential for Precise Robotic Actuation?

Robotics relies heavily on precise and controlled movement. Ring magnets, because of their unique shape and magnetic properties, play a vital role in achieving this precision. Think about the intricate movements of a robotic arm – the accuracy and responsiveness are often powered by ring magnets working within actuators.

These actuators, essentially the "muscles" of the robot, can use ring magnets in several ways. For instance, they can be incorporated into rotary motors that provide continuous rotational force. Alternatively, they can form part of linear actuators that provide push-pull motion. The key advantage lies in the control they offer over the magnetic field, enabling fine-tuning of the actuation force and speed. This level of control translates directly into more accurate and responsive robotic movements.

How Do Ring Magnets Contribute to Advanced Robotic Sensors?

Beyond actuation, ring magnets are also instrumental in creating advanced robotic sensors. Many sensors rely on detecting changes in magnetic fields to measure position, velocity, or force. The consistent and reliable magnetic field produced by ring magnets makes them ideal for these applications.

Imagine a robot navigating a complex environment. It needs to "see" its surroundings, and sensors are its eyes. Ring magnets can be used in sensors that detect the proximity of objects, the orientation of joints, or even the force being applied by a gripper. For example, when a robot picks up an object, sensors with ring magnets can accurately measure the gripping force, preventing damage to fragile items while ensuring a secure hold on heavier ones. This sensory feedback is crucial for autonomous operation and decision-making.

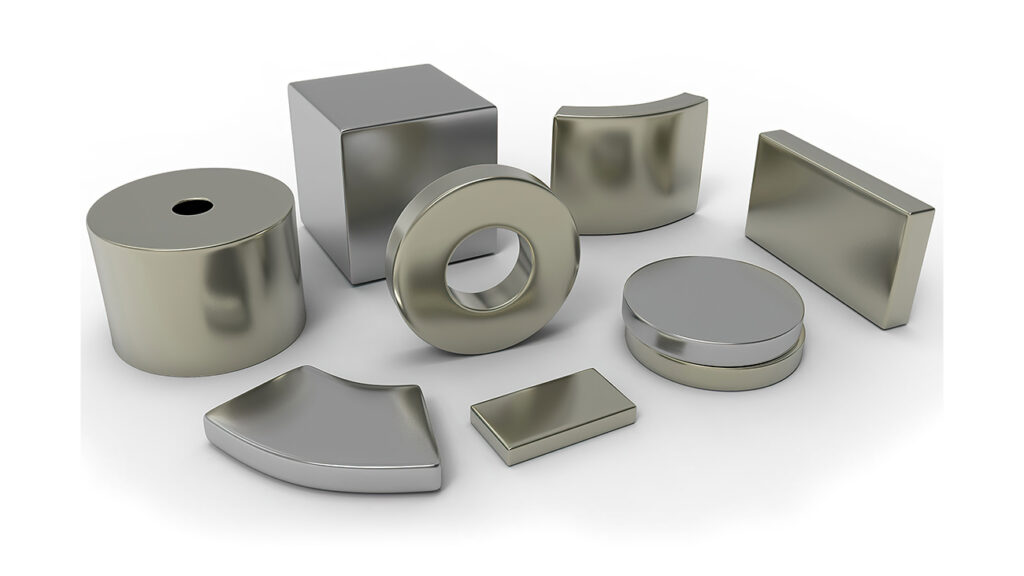

What Types of Ring Magnet Materials are Best Suited for Robotic Applications?

The choice of material for a ring magnet is paramount. Consider the harsh realities of robotic environments. High temperatures, mechanical stress, and even corrosive substances are commonplace. Therefore, selecting the right magnetic material becomes a critical decision for durability and optimal performance.

- Neodymium (NdFeB) Magnets: Renowned for their exceptionally high magnetic strength, neodymium ring magnets are a popular choice when maximum power is needed in a compact size. They’re ideal for robotic arms and other applications that require high torque or force.

- Samarium Cobalt (SmCo) Magnets: While slightly less powerful than neodymium magnets, samarium cobalt magnets offer excellent temperature stability and corrosion resistance. This makes them well-suited for robots operating in extreme environments, such as high-temperature manufacturing processes.

- Ferrite Magnets: This choice offers a cost-effective option for less demanding applications. Their resistance to corrosion is high. They are used in some simpler robotic applications.

Table: Comparison of Ring Magnet Materials

| Material | Strength | Temperature Resistance | Corrosion Resistance | Cost | Applications |

|---|---|---|---|---|---|

| Neodymium (NdFeB) | Very High | Moderate | Poor (Requires Coating) | High | High-Power Actuators, Small Motors |

| Samarium Cobalt (SmCo) | High | High | Excellent | Very High | High-Temperature Environments, Corrosive Areas |

| Ferrite | Moderate | Moderate | Excellent | Low | Basic Sensors, Low-Power Motors |

How Can Ring Magnet Arrays Enhance Force and Uniformity in Robotics?

It’s one thing to use a single ring magnet, but quite another to arrange multiple rings strategically to create a magnet array. This arrangement can drastically improve the strength and uniformity of the magnetic field, thus providing enhanced control over the actuation and sensing mechanisms in robots.

By carefully positioning and orienting multiple ring magnets, engineers can create a magnetic field profile that perfectly matches the needs of a specific robotic application. For instance, in a linear actuator, an array of ring magnets can generate a more uniform force along the entire stroke length. Similarly, in a rotary motor, arranging ring magnets in a specific pattern can minimize torque ripple, resulting in smoother and more precise rotation.

What Role Do Ring Magnets Play in Robotic Grippers and End Effectors?

Robotic grippers are the "hands" of a robot, and they must be versatile and adaptable to handle a wide range of objects. Ring magnets are playing a vital role in shaping the design of advanced robotic grippers and end effectors by providing clamping pressure.

Permanent magnet grippers use the attractive force of the magnet. electromagnetic grippers use magnetization and demagnetization of a magnetic structure to pick up the desired item.

Consider a warehouse robot tasked with picking up boxes of various sizes and weights. A gripper equipped with strategically placed ring magnets can provide a strong and reliable grip on boxes of different materials without scratching. This grip force can also be adjusted by controlling the magnetization of the magnets, allowing the gripper can handle fragile objects gently and heavier items securely.

Can Ring Magnets Improve the Efficiency of Robotic Motors?

Efficiency is a crucial consideration for any robotic system, especially battery-powered mobile robots. Any gains in energy efficiency translate directly into longer operating times and greater overall system efficiency. Using ring magnets in the design of robotic motors allows for increased output.

By carefully selecting the type and arrangement of ring magnets in the motor’s rotor and stator, engineers can minimize energy losses due to friction and magnetic field leakage. High-performance ring magnets, such as neodymium magnets, can generate a stronger magnetic field with less electrical current, thereby reducing energy consumption and improving motor efficiency. This is especially true in robotics.

What Are Some Example of Current Robotics Applications Benefiting from Ring Magnets?

To truly understand the impact of ring magnets in robotics, let’s look at some real-world examples:

- Medical Robotics: Ring magnets are critical components in surgical robots where precise movements are crucial. Actuators powered by ring magnets allow surgeons to perform delicate procedures with greater accuracy and control.

- Industrial Automation: In manufacturing, robots equipped with ring magnet-based grippers and actuators are used for tasks that require high precision and speed, such as assembling electronic components or packaging food products.

- Aerospace: Robots with enhanced ring magnet implementations are crucial for inspections and maintenance due to the precision the robot provides. These robots can be fitted with sensors powered by high-quality ring magnets.

Case Study: Ring Magnets in Surgical Robotics

A leading surgical robot manufacturer utilizes neodymium ring magnets in their miniature actuators, allowing surgeons to perform minimally invasive procedures. The high magnetic strength of the magnets enables compact and precise movements within the confined space of the human body, resulting in reduced trauma and faster recovery times for patients. This technology has revolutionized numerous surgical procedures, from cardiac surgery to neurosurgery.

What Future Trends Will Further Leverage Ring Magnet Technology in Robotics?

The future of robotics is inextricably linked to advancements in magnet technology, particularly in the area of ring magnets. As materials science continues to evolve, we can expect to see even more powerful and versatile ring magnets that unlock new possibilities for robotic design and control.

One exciting trend is the development of "smart" magnets that can dynamically adjust their magnetic field strength in response to external stimuli. This could lead to robots with grippers that automatically adapt to the shape and weight of an object, or actuators that provide variable stiffness for enhanced safety and performance.

Another promising area is the integration of ring magnets with micro-robotics. Tiny robots powered by miniature ring magnets could one day be used for targeted drug delivery, environmental monitoring, or even microsurgery.

How Can I Choose the Right Ring Magnet Supplier for My Robotics Project?

Selecting the appropriate ring magnet supplier is vital for ensuring the success of your project. You need a partner who can provide high-quality products, technical expertise, and reliable support. Here are some key factors to consider:

- Experience and Reputation: Look for a supplier with a proven track record in providing ring magnets for robotic applications. Check online reviews and ask for references to assess their reputation.

- Product Quality and Consistency: Ensure that the supplier uses high-quality materials and has rigorous quality control procedures in place. Request samples and test them thoroughly before committing to a large order.

- Technical Support: Choose a supplier who can provide technical support and guidance on magnet selection, design, and application. They should have experienced engineers and experts who can answer your questions and help you optimize your design.

- Customization Options: If your project requires custom-shaped or custom-magnetized rings, select a supplier capable to produce these specific design requirements.

How Can I Effectively Integrate Ring Magnets Into My Robotic Designs?

Integrating ring magnets effectively into your robotic designs requires careful planning, a thorough understanding of your application, and a deep knowledge of magnet properties. Here are some best practices to follow:

- Define Your Requirements: Clearly define your application’s force, speed, and accuracy requirements. This will help you determine the appropriate type and size of ring magnets for your project.

- Consider the Magnetic Circuit: Think about how magnets are positioned relative to each other, and what the effect will be on your circuit design.

- Test and Validate: Build prototypes and test them thoroughly to validate your design. A few tests will uncover ways to improve your project before committing to the final product.

FAQs About Ring Magnets in Robotics:

What is the primary benefit of using ring magnets over other shapes in robotic actuators?

Ring magnets offer unique flux paths that can be optimized for linear or rotary motion, leading to more efficient and compact actuators. This makes them ideal for applications where space and weight are limited. Additionally, the central hole in the ring magnet can often be used to pass wires or shafts, further simplifying the design.

Do shielding requirements increase when using ring magnets?

Shielding requirements typically depend on the magnetic field strength and the sensitivity of nearby components. While ring magnets often have a concentrated magnetic field, careful design and placement can minimize the need for extensive shielding. In some cases, the ring shape can even make shielding easier by containing the magnetic field within a defined area.

How does the choice of coating influence a ring magnets effectiveness in a robotics implementation?

The coating plays a significant role in protecting the magnet from corrosion and abrasion, thereby prolonging its lifespan and integrity. Coatings such as nickel, epoxy, or parylene are frequently used, depending on the specific environmental conditions of the robotic application. The coating choice also must be balanced against any potential impact on the magnetic performance of the magnet.

What safety precautions should I take when handling strong ring magnets during robotic assembly?

Strong ring magnets can pose several safety hazards if not handled carefully. They can pinch fingers, damage electronic devices, and even interfere with pacemakers. Always wear appropriate personal protective equipment, such as gloves and safety glasses, and keep magnets away from sensitive electronics and metallic objects. Use caution when bringing magnets together to avoid sudden and forceful impacts which could lead to cracking or shattering of magnets.

How do I calculate the magnetic force generated by a ring magnet in my actuator design?

Calculating the magnetic force generated by a ring magnet can be complex and require specialized software or tools. A simple method is to begin with the ideal calculated result. The ideal answer can then be adjusted based on some estimated losses that will occur in the actual circuit design. Use simulations that use finite element analysis (FEA software).

What are the key considerations for selecting the right grade of neodymium magnet (e.g., N35, N42, N52) for a robotic application?

When choosing a grade of neodymium magnet for any application, be sure to balance the total power of the actuator with the size, weight, and cost of the magnet. Higher grades will deliver greater strength, but often at a higher cost and potentially lower temperature resistance. A more robust magnet is often a better choice.

Conclusion:

Ring magnets are indispensable components in modern robotics, powering movement and enabling advanced sensing capabilities. Their unique properties, combined with ongoing advancements in materials science, continue to drive innovation in this exciting field. From surgical robots to industrial automation, the possibilities for ring magnet applications are virtually limitless.

- Ring magnets are essential for precise robotic actuation, offering fine control over movement.

- They play a crucial role in creating advanced robotic sensors, enabling robots to "see" and interact with their environment.

- The choice of ring magnet material depends on the specific application’s demands, with neodymium, samarium cobalt, and ferrite magnets being common options.

- Ring magnet arrays can enhance force and uniformity in robotic systems, providing greater performance in advanced applications.

- Selecting the right ring magnet supplier and following best practices for integration are crucial for success.

I hope this article has shed new light on the exciting world of ring magnets and their importance in the ever-evolving field of robotics. There will be rapid advances that are beneficial to robotics as material science and manufacturing processes become more efficient. Keep exploring, keep innovating, and keep pushing the boundaries of what these fantastic components can do!