Magnets are an integral part of modern technology, with applications ranging from motors and generators to medical imaging and data storage. The development of shaped magnet technology and advanced magnetic materials has opened up new possibilities for the design and performance of magnetic devices. This article will explore the future of magnetic solutions, focusing on the latest advancements in shaped magnet technology and materials.

Shaped Magnet Technology

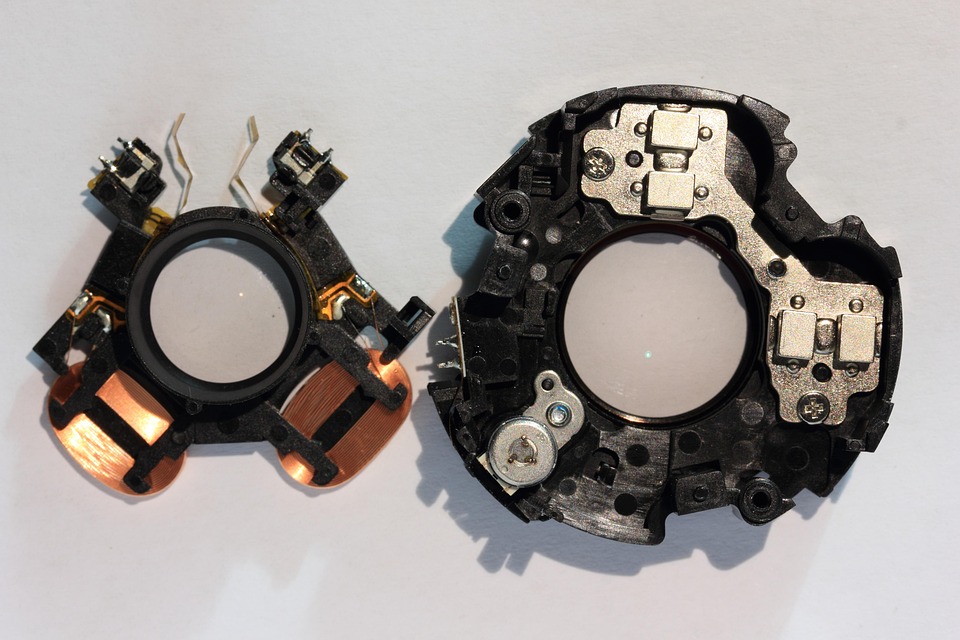

Shaped magnet technology refers to the process of manufacturing magnets with specific geometries and magnetic properties to suit specific applications. This approach allows for the optimization of magnetic performance, size, weight, and cost, leading to more efficient and reliable devices.

1. Additive Manufacturing

Additive manufacturing, also known as 3D printing, has revolutionized the way magnets are produced. This technology allows for the direct fabrication of complex magnetic shapes and structures, eliminating the need for traditional manufacturing methods, such as machining and molding.

The use of 3D printing in magnet manufacturing offers several advantages. First, it enables the production of complex magnetic geometries that cannot be easily achieved through conventional methods. This freedom of design leads to improved magnetic performance and reduced material waste.

Second, additive manufacturing allows for rapid prototyping and customization of magnets. This feature is particularly beneficial in applications where custom-shaped magnets are required, as it reduces the time and cost associated with traditional prototyping methods.

2. Laser-Assisted Manufacturing

Laser-assisted manufacturing is another advanced manufacturing technique that has found applications in the production of shaped magnets. This technology utilizes laser beams to selectively heat and shape magnetic materials, allowing for high levels of precision and control over the final shape and magnetic properties of the magnet.

Laser-assisted manufacturing offers several advantages over conventional manufacturing methods. For instance, it enables the production of high-resolution magnetic structures with features as small as a few micrometers. Additionally, this technique allows for the production of magnets with graded magnetic properties, which cannot be easily achieved through other methods.

Advanced Magnetic Materials

The performance of magnetic devices is closely linked to the properties of the magnetic materials used in their construction. Recent advancements in materials science have led to the development of new and improved magnetic materials with enhanced magnetic properties and functionalities.

1. Rare Earth Magnets

Rare earth magnets, such as neodymium magnets, are known for their exceptional magnetic properties, including high magnetic strength and resistance to demagnetization. These properties make them ideal for use in high-performance applications, such as electric motors, generators, and magnetic resonance imaging (MRI) systems.

Recent advancements in rare earth magnet technology have focused on improving their magnetic properties while reducing their reliance on rare earth elements. For example, researchers have developed new magnet alloys that incorporate less-scarce elements, such as iron and boron, to replace some of the rare earth elements without compromising magnetic performance.

2. Ferromagnetic Materials

Ferromagnetic materials, such as iron and nickel, are the most common type of magnetic materials used in applications ranging from electrical motors to magnetic storage devices. Recent research has focused on developing new ferromagnetic materials with improved magnetic properties and enhanced functionalities.

For instance, researchers have developed new ferromagnetic alloys with higher Curie temperatures, which allow for their use in high-temperature applications without significant loss of magnetic properties. Additionally, researchers have investigated the use of nanostructured ferromagnetic materials, which exhibit enhanced magnetic properties and potential applications in spintronic devices.

Applications of Shaped Magnet Technology and Advanced Materials

The combination of shaped magnet technology and advanced magnetic materials has opened up new possibilities for the design and performance of magnetic devices across various industries.

1. Electric Vehicles

Electric vehicles (EVs) rely on electric motors for propulsion, and the performance of these motors is directly linked to the quality of the magnets used in their construction. Shaped magnet technology and advanced magnetic materials have enabled the development of more efficient and compact electric motors with higher torque densities and lower energy losses.

For example, shaped rare earth magnets can be optimized for specific motor designs, resulting in improved efficiency and reduced material usage. Additionally, the use of high-temperature ferromagnetic materials in motor components allows for increased operating temperatures without compromising performance.

2. Wind Energy

Wind energy turbines use generators to convert kinetic energy from wind into electrical energy. The efficiency of these generators depends on the performance of the permanent magnets used in their construction.

Advancements in shaped magnet technology and magnetic materials have led to the development of more efficient and reliable wind turbine generators. For instance, shaped neodymium magnets can be optimized for specific generator designs, leading to reduced material usage and improved generator efficiency.

3. Medical Imaging and Diagnostics

Magnetic resonance imaging (MRI) and other medical imaging technologies rely on the use of strong and homogeneous magnetic fields to produce high-resolution images of the human body. Shaped magnet technology and advanced magnetic materials have played a crucial role in the development of more powerful and compact MRI systems with improved image quality.

For example, shaped superconducting magnets can be tailored to produce highly uniform magnetic fields, which are essential for high-resolution MRI imaging. Additionally, the development of high-field strength magnets has enabled the development of MRI systems with higher field strengths, resulting in improved image resolution and shorter scan times.

Conclusion

The future of magnetic solutions is bright, with advancements in shaped magnet technology and materials paving the way for more efficient, compact, and reliable magnetic devices. Shaped magnet technology has enabled the optimization of magnetic performance, size, weight, and cost, while the development of advanced magnetic materials has led to improvements in magnetic strength, temperature stability, and customization.

These advancements have significant implications across a wide range of industries, including electric vehicles, wind energy, and medical imaging. As research in this field continues, we can expect to see further improvements in magnetic device performance and the emergence of new applications that harness the unique properties of shaped magnets and advanced magnetic materials.

FAQs

1. What are shaped magnets?

Shaped magnets are magnets that have been manufactured into specific geometries or shapes to optimize their magnetic properties for specific applications.

2. What is shaped magnet technology?

Shaped magnet technology refers to the processes and techniques used to manufacture magnets with specific shapes and magnetic properties to suit particular applications.

3. What are the benefits of shaped magnet technology?

Shaped magnet technology offers several benefits, including improved magnetic performance, reduced material usage, and the ability to create custom-shaped magnets for specific applications.

4. What are advanced magnetic materials?

Advanced magnetic materials are materials with enhanced magnetic properties and functionalities compared to traditional magnetic materials. These materials are often developed through advances in materials science and engineering.

5. What are some applications of shaped magnet technology and advanced magnetic materials?

Shaped magnet technology and advanced magnetic materials have applications in various industries, including electric vehicles, wind energy, medical imaging, and data storage. These advancements have led to the development of more efficient, compact, and reliable magnetic devices.