Summary: Dive into the fascinating world of neodymium magnets, the undisputed champions of permanent magnetism. This comprehensive guide unravels the exceptional properties that make these magnets so potent – from their unparalleled magnetic strength to their unique performance characteristics. Discover the vast landscape of applications where neodymium magnets are indispensable, powering everything from smartphones and electric vehicles to medical breakthroughs and renewable energy technologies. Understand why these magnets are not just components, but crucial enablers of modern innovation, driving technological advancements and shaping industries across the globe.

The Rise of Rare Earth Magnets: Neodymium Takes Center Stage

The quest for stronger and more efficient magnets has been a relentless journey throughout history. From lodestones to alnico and ferrite magnets, each era brought advancements in magnetic materials. However, the dawn of rare earth magnets in the late 20th century marked a revolutionary leap forward. Within this class, neodymium magnets emerged as the undisputed leader, surpassing all predecessors in magnetic strength. These magnets, composed primarily of neodymium, iron, and boron (NdFeB), immediately captivated the scientific and engineering communities with their unprecedented magnetic performance. The discovery and subsequent refinement of neodymium magnets were not merely an incremental improvement; they represented a paradigm shift, unlocking possibilities previously confined to the realm of theoretical concepts. This section will explore the historical context of magnetic materials and pinpoint the crucial role of neodymium magnets in ushering in a new age of magnetic technology.

Neodymium’s prominence stems from its unique atomic structure and electronic configuration, allowing it to interact with magnetic fields in an exceptionally powerful way. Unlike ferrite magnets, which are ceramic-like and relatively weak, or alnico magnets, which are brittle and less energy-efficient, neodymium magnets boast a far superior combination of magnetic remanence, coercivity, and energy product. Remanence refers to the strength of the magnetic field a material retains after being magnetized, coercivity measures its resistance to demagnetization, and energy product quantifies the overall energy storage capability of the magnet. Neodymium magnets excel across all these parameters, resulting in magnets that are not only incredibly strong but also remarkably stable and efficient in various operating conditions. This combination of superior properties has propelled neodymium magnets to the forefront of diverse applications where high performance and miniaturization are paramount.

Unmatched Magnetic Strength: The Powerhouse of Magnetic Materials

The defining characteristic of neodymium magnets, and perhaps the most widely recognized attribute, is their extraordinary magnetic strength. They are, quite simply, the strongest type of permanent magnet commercially available today. This remarkable strength isn’t just a theoretical advantage; it translates into tangible benefits across countless applications. Compared to traditional magnet types like ferrite or alnico magnets of the same volume, a neodymium magnet can generate a magnetic field many times stronger. This immense magnetic force allows engineers to design significantly smaller and lighter devices while maintaining or even enhancing performance. The sheer power of these magnets is often demonstrated by their ability to lift objects hundreds or even thousands of times their own weight, captivating audiences and highlighting their truly exceptional capabilities.

This unparalleled strength is quantified by several key magnetic properties. Remanence (Br), often measured in Tesla (T) or Gauss (G), indicates the strength of the magnetic field remaining in the material after the magnetizing field is removed. Neodymium magnets exhibit exceptionally high remanence values compared to other permanent magnet materials. Coercivity (Hc), measured in Oersteds (Oe) or kA/m, describes the material’s resistance to demagnetization. High coercivity is crucial for applications where magnets are exposed to external magnetic fields or elevated temperatures. Neodymium magnets, particularly high-coercivity grades, demonstrate excellent resistance to demagnetization, ensuring stable performance in demanding environments. Finally, the energy product (BHmax), measured in Mega Gauss Oersteds (MGOe) or kJ/m³, represents the maximum energy that can be stored in a magnet and is a crucial indicator of a magnet’s overall performance capability. Neodymium magnets consistently deliver the highest energy product values among permanent magnets, solidifying their position as the pinnacle of magnetic strength.

Demagnetization Resistance: Maintaining Magnetism Under Pressure

While sheer magnetic strength is a primary advantage, the ability to retain that strength under challenging conditions is equally critical for many applications. Demagnetization, the partial or complete loss of magnetization, can occur when a magnet is exposed to adverse conditions such as high temperatures, strong opposing magnetic fields, or mechanical shock. Neodymium magnets, especially certain grades, exhibit impressive resistance to demagnetization, making them reliable even in demanding operating environments. This characteristic distinguishes them from some other high-performance magnets that might be strong but more susceptible to losing their magnetic properties over time or under stress.

The coercivity of a neodymium magnet, as previously mentioned, is a key indicator of its demagnetization resistance. Higher coercivity values signify a greater ability to withstand external demagnetizing forces. Manufacturers produce various grades of neodymium magnets, often categorized by their coercivity levels to suit different application requirements. "High-coercivity" and "ultra-high coercivity" neodymium magnets are specifically designed for applications where they will be subjected to elevated temperatures or strong opposing fields, such as in motors operating in harsh environments or magnetic bearings. Furthermore, the shape and design of a magnet also play a role in its demagnetization resistance. Magnets with a long magnetic length relative to their cross-sectional area are generally more resistant to demagnetization. Engineers carefully consider these factors when selecting and designing with neodymium magnets to ensure long-term performance and reliability in their intended applications.

Diverse Grades and Shapes: Tailoring Magnets to Specific Needs

Neodymium magnets are not a monolithic product; they are available in a wide array of grades and shapes, allowing engineers to precisely tailor their magnetic properties and physical forms to the specific requirements of diverse applications. This versatility is a significant factor contributing to their widespread adoption across industries. Different grades are achieved by varying the composition of the NdFeB alloy and employing different manufacturing processes. These grade variations primarily affect magnetic properties like remanence, coercivity, and maximum operating temperature. For instance, high-energy grades maximize magnetic strength for applications demanding the most powerful magnetic fields, while high-coercivity grades prioritize resistance to demagnetization in demanding thermal or magnetic environments.

In terms of shapes, neodymium magnets can be manufactured into virtually any form imaginable. Common shapes include blocks, discs, rings, cylinders, segments, and arcs. However, custom shapes are also readily produced to fit the exact geometries required by specific designs. This shaping flexibility is crucial for integrating magnets seamlessly into intricate mechanisms and electronic devices. The ability to produce complex shapes also enables the optimization of magnetic flux paths and field distributions for enhanced performance and efficiency. Advanced machining and cutting techniques, combined with various coating options to protect against corrosion and wear, further expand the possibilities of neodymium magnet design and application. This customizability ensures that neodymium magnets can be optimized for performance, size, and integration into virtually any system requiring powerful and precise magnetic fields.

Manufacturing Magic: The Sintering Process of Neodymium Magnets

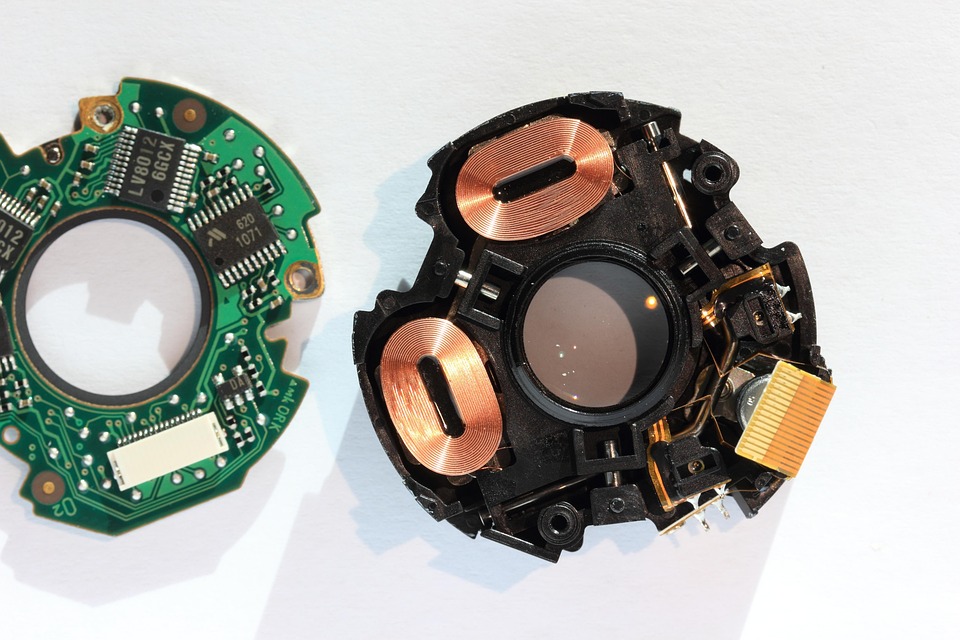

The exceptional properties of neodymium magnets are not just inherent to the constituent materials; they are also critically dependent on a sophisticated and carefully controlled manufacturing process, primarily the sintering process. This method, involving powder metallurgy techniques, is essential for achieving the desired microstructure and magnetic alignment within the magnet, ultimately dictating its performance characteristics. The manufacturing journey begins with meticulously blending neodymium, iron, boron, and often other additives in carefully controlled proportions. This mixture is then subjected to a process called jet milling or ball milling, which reduces the materials into a fine powder with particle sizes often measured in micrometers. The finer the powder, the better the resulting magnet’s homogeneity and properties.

The next crucial stage is pressing. The fine powder is compacted under high pressure in a die, often in the presence of a strong magnetic field. This magnetic field alignment step is paramount for achieving anisotropy in the magnet – aligning the magnetic domains in a preferred direction to maximize magnetic strength. The pressed compact, known as a "green compact," is still fragile and porous. This is where sintering comes in. Sintering involves heating the green compact to a high temperature, typically around 1000-1100°C, in a vacuum or inert atmosphere. During sintering, the powder particles fuse together, reducing porosity and densifying the material, creating a solid, robust magnet. After sintering, the magnets undergo a series of machining, grinding, and cutting operations to achieve the final desired shape and dimensions. Finally, surface treatments, such as plating with nickel, epoxy coating, or Parylene coating, are often applied to protect the magnets from corrosion and enhance their durability. This intricate sintering process, requiring precise control over temperature, pressure, atmosphere, and magnetic field orientation, is what unlocks the full potential of neodymium magnets.

Powering Consumer Electronics: From Smartphones to Headphones

Neodymium magnets have become indispensable components in a vast array of consumer electronic devices, significantly contributing to the miniaturization, performance, and efficiency of modern gadgets. Their high magnetic strength allows designers to create smaller and lighter components without compromising functionality, a critical factor in the ever-shrinking world of portable electronics. From smartphones and tablets to laptops and headphones, neodymium magnets are quietly but powerfully at work behind the scenes, enabling features we often take for granted. The compact size and high performance of these magnets have been instrumental in driving innovation and shaping the landscape of modern consumer technology.

In smartphones and tablets, tiny neodymium magnets are crucial for various functions. They are found in speakers, microphones, and haptic feedback systems, converting electrical signals into sound and vibrations with remarkable clarity and precision. Camera modules often utilize neodymium magnets in autofocus and image stabilization systems, ensuring crisp and steady images. In hard disk drives (HDDs), although increasingly being replaced by solid-state drives (SSDs), neodymium magnets are still vital for positioning the read/write heads with speed and accuracy, enabling data storage and retrieval. High-quality headphones and earbuds rely heavily on neodymium magnet-based drivers to produce rich, detailed, and immersive audio experiences, pushing the boundaries of sound reproduction in portable formats. Even seemingly mundane devices like magnetic phone holders and stylus pens often leverage the strong holding power of neodymium magnets. The pervasive presence of neodymium magnets within consumer electronics serves as a testament to their versatility and enabling role in shaping our daily digital lives.

Revolutionizing Renewable Energy: Wind Turbines and Beyond

The global push towards sustainable and renewable energy sources has created burgeoning demand for neodymium magnets, particularly in wind turbine technology. These magnets play a pivotal role in the generators of modern wind turbines, enabling more efficient and powerful energy conversion. As the world seeks to reduce its reliance on fossil fuels, the role of neodymium magnets in renewable energy infrastructure is only set to grow, highlighting their importance in addressing critical energy challenges. Beyond wind turbines, neodymium magnets are also finding increasing applications in other renewable energy technologies, further solidifying their position as essential components in the transition to a cleaner energy future.

In direct-drive wind turbines, which are becoming increasingly prevalent, neodymium magnets are integrated into the generator’s rotor. These magnets create a strong and consistent magnetic field that interacts with rotating coils, generating electricity without the need for a gearbox. Gearless direct-drive systems offer numerous advantages, including increased efficiency, reduced maintenance, and higher reliability, all partly enabled by the high performance of neodymium magnets. The powerful magnetic field produced by these magnets allows for generators that are more compact and lightweight compared to traditional generators using ferrite magnets or electromagnets. Furthermore, neodymium magnets are being explored for use in other renewable energy technologies, such as wave energy converters and tidal power generators, where their high energy density and efficiency are highly beneficial. Their contribution extends beyond energy generation into energy storage systems as well, with potential applications in high-performance batteries and flywheels. The renewable energy sector represents a significant and growing market for neodymium magnets, underscoring their role in the global transition towards a sustainable energy future.

Medical Marvels: Applications in MRI and Beyond

Neodymium magnets have revolutionized medical technology, finding critical applications in advanced diagnostic imaging, therapeutic devices, and research equipment. Their exceptional magnetic strength and compact size are particularly advantageous in medical contexts, where precise control, minimally invasive procedures, and high-resolution imaging are paramount. From Magnetic Resonance Imaging (MRI) scanners to specialized surgical instruments, neodymium magnets contribute significantly to improving healthcare and advancing medical knowledge. Their applications span a wide spectrum, from large-scale diagnostic equipment to miniature implantable devices, demonstrating their versatility in the medical field.

MRI scanners, a cornerstone of modern medical diagnostics, often utilize superconducting magnets to generate the powerful magnetic fields required for imaging. However, in certain specialized MRI applications, and increasingly in portable and open MRI systems, high-grade neodymium magnets are employed. While not as powerful as superconducting magnets, neodymium magnets offer significant advantages in terms of size, cost, and ease of maintenance, making MRI technology more accessible and versatile. Beyond MRI, neodymium magnets are crucial in various medical devices. They are used in magnetic drug delivery systems to target medications directly to specific areas in the body, minimizing side effects and enhancing treatment efficacy. In surgical instruments, they power minimally invasive tools, enabling precise manipulation and tissue retraction during delicate procedures. Hearing aids and cochlear implants often utilize tiny neodymium magnets for improved sound quality and device performance. Furthermore, in medical research, neodymium magnets are indispensable in laboratory equipment like magnetic stirrers and separators, crucial for various bio-chemical and cell biology experiments. The medical field continues to explore and expand the applications of neodymium magnets, driven by their unique properties to enhance diagnostics, therapies, and medical research.

Automotive Advancements: Driving Electric Vehicles and Beyond

The automotive industry is undergoing a transformative shift towards electrification, and neodymium magnets are playing a crucial role in enabling this revolution. Electric vehicles (EVs) and hybrid electric vehicles (HEVs) rely heavily on high-performance electric motors, and neodymium magnets are often the material of choice for these motors due to their exceptional power-to-weight ratio and efficiency. Beyond electric powertrains, neodymium magnets are also finding increasing applications in other automotive systems, contributing to improved performance, safety, and fuel efficiency in both traditional and electric vehicles. Their impact on the automotive sector spans from core propulsion systems to auxiliary functions, demonstrating their broad utility in modern vehicle design.

In EV and HEV powertrains, neodymium magnets are commonly used in permanent magnet synchronous motors (PMSMs), which are known for their high efficiency, power density, and torque characteristics. These motors directly drive the wheels or provide power assist in hybrid systems. The strong magnetic field of neodymium magnets allows for smaller and lighter motors, crucial for maximizing vehicle range and performance. Beyond propulsion, neodymium magnets are also employed in various sensors throughout vehicles, including speed sensors, position sensors, and torque sensors, which are vital for safety systems like ABS and electronic stability control, as well as for advanced driver-assistance systems (ADAS). Automotive speakers also benefit from neodymium magnets, delivering better sound quality in car audio systems. Even in traditional internal combustion engine vehicles, neodymium magnets contribute to improved fuel efficiency and performance through applications in starter motors, alternators, and fuel pumps. As the automotive industry continues its electrification journey and incorporates more advanced technologies, the demand for neodymium magnets is poised to rise further, cementing their position as key enablers of automotive innovation.

Handling and Safety: Respecting the Power of Neodymium Magnets

While neodymium magnets are incredibly useful and powerful, their strength also necessitates careful handling and awareness of potential safety considerations. Their intense magnetic attraction can pose risks if not managed properly, both in industrial and consumer settings. Understanding the potential hazards and adopting appropriate handling techniques is crucial for ensuring safe and responsible use of these magnets. This awareness is particularly important given their increasing prevalence in everyday devices and applications.

One of the primary safety concerns is the "pinch point" hazard. Neodymium magnets can attract each other with such force that body parts caught between them can be severely pinched or crushed. Therefore, it is crucial to keep fingers and other body parts clear when handling multiple neodymium magnets, especially larger ones. Children should always be supervised when around these magnets, as they may not understand the risks. Another potential hazard is the fragility of sintered neodymium magnets. They are brittle and can chip or shatter if subjected to impact or sudden temperature changes. These fragments can be sharp and pose a cutting hazard. Furthermore, loose fragments can also be attracted to other magnets at high velocity, becoming projectiles. For individuals with pacemakers or other implanted medical devices, strong magnetic fields can interfere with device function. It’s advisable to keep neodymium magnets away from such devices. When transporting or storing neodymium magnets, they should be properly packaged to prevent them from attracting to each other or to ferromagnetic materials, which could lead to damage or unexpected hazards. By understanding these potential risks and adhering to safe handling practices, the benefits of neodymium magnets can be harnessed responsibly and safely.

The Future of Neodymium Magnets: Research and Innovation

The field of neodymium magnets is not static; ongoing research and innovation continue to push the boundaries of their performance and broaden their applications. Scientists and engineers are actively exploring new materials, manufacturing processes, and design strategies to further enhance the properties of these magnets, address existing limitations, and discover novel uses. This continuous innovation is crucial for maintaining the relevance and expanding the impact of neodymium magnets in a rapidly evolving technological landscape. The future of neodymium magnets promises even greater performance, efficiency, and versatility, solidifying their position as indispensable materials for the 21st century and beyond.

Current research focuses on several key areas. One area is improving the high-temperature performance of neodymium magnets. While standard grades are limited by their Curie temperature and can experience demagnetization at elevated temperatures, researchers are exploring alloying strategies, such as adding dysprosium or terbium, or grain boundary diffusion techniques, to enhance high-temperature coercivity and stability. However, dysprosium and terbium are also rare earth elements with limited availability and high cost, prompting research into dysprosium-free or dysprosium-reduced neodymium magnets. Another area of focus is developing new manufacturing processes to reduce costs and improve efficiency. Alternative sintering techniques, additive manufacturing approaches like 3D printing, and powder injection molding are being investigated to potentially lower production costs and enable more complex magnet geometries. Furthermore, researchers are exploring novel applications for neodymium magnets in emerging fields, such as advanced sensors, quantum computing, and aerospace technologies, further expanding their reach and impact. The ongoing research and development efforts ensure that neodymium magnets will remain at the forefront of magnetic technology, driving innovation and enabling future technological breakthroughs.

Conclusion: The Indispensable Powerhouse of Modern Technology

Neodymium magnets stand as a testament to human ingenuity in material science and engineering. Their remarkable combination of unmatched magnetic strength, excellent demagnetization resistance, and versatility in grades and shapes has propelled them to the forefront of countless applications across diverse industries. From powering the smartphones in our pockets to enabling the turbines generating clean energy, neodymium magnets are the unsung heroes behind much of modern technology. Their impact is not merely incremental; they are enabling technologies, facilitating miniaturization, enhancing performance, and driving efficiency across a vast spectrum of devices and systems.

As we look towards the future, the importance of neodymium magnets is only set to grow. The continued push for electrification in transportation, the expansion of renewable energy infrastructure, and the relentless drive for smaller, more powerful, and more efficient electronic devices all rely heavily on the unique capabilities of these magnets. Ongoing research and innovation promise even further advancements in their properties and applications, ensuring their continued relevance and indispensability in the decades to come. While responsible sourcing, handling, and recycling remain crucial considerations, the undeniable benefits and pervasive applications of neodymium magnets solidify their position as a cornerstone material of the 21st century, and a key enabler of technological progress across the globe. They truly represent the "Powerful Field" they generate, both literally and figuratively, in shaping the modern world.

FAQ

What are neodymium magnets and why are they so strong?

Neodymium magnets are permanent magnets made from an alloy of neodymium, iron, and boron (NdFeB). They are the strongest type of commercially available permanent magnet due to the unique atomic structure of neodymium and the specific arrangement of atoms in the NdFeB alloy, which allows for exceptional alignment of magnetic domains. This alignment, achieved through a specialized sintering process in a magnetic field, maximizes their magnetic strength, resulting in significantly higher remanence, coercivity, and energy product compared to other magnet types.

Are neodymium magnets dangerous?

While generally safe when handled responsibly, neodymium magnets can pose certain risks due to their powerful magnetic attraction. The primary dangers include pinch point hazards (fingers or body parts caught between magnets), risk of chipping or shattering (creating sharp fragments), and potential interference with pacemakers or other implanted medical devices. It is important to handle them with care, especially larger magnets, keep them away from children and individuals with medical implants, and store them properly to avoid accidental damage or hazards.

Can neodymium magnets lose their magnetism over time?

Neodymium magnets are permanent magnets and are designed to retain their magnetism for a very long time under normal operating conditions. However, they can lose magnetism if exposed to excessively high temperatures (above their Curie temperature, which varies by grade) or strong opposing magnetic fields that exceed their coercivity. Certain grades are specifically designed with higher coercivity and thermal stability for applications requiring resistance to demagnetization in demanding environments. Under typical use, neodymium magnets will maintain their magnetic strength for decades.

What are some common applications of neodymium magnets?

Neodymium magnets have an incredibly wide range of applications across various industries. Some common examples include:

- Consumer Electronics: Smartphones, tablets, laptops, headphones, speakers, microphones, hard disk drives.

- Renewable Energy: Wind turbine generators.

- Medical Technology: MRI scanners, magnetic drug delivery systems, surgical instruments, hearing aids.

- Automotive Industry: Electric vehicle motors, hybrid vehicle motors, sensors, speakers, automotive components.

- Industrial Applications: Motors, generators, actuators, magnetic separators, magnetic bearings, magnetic couplings.

- Household and Everyday Use: Magnetic closures, magnetic holders, toys, science experiments.

Are neodymium magnets environmentally friendly?

The environmental impact of neodymium magnets is a complex issue. The mining and processing of rare earth elements like neodymium can have environmental consequences, including habitat disruption and pollution. However, neodymium magnets also play a crucial role in enabling green technologies like wind turbines and electric vehicles, which contribute to reducing reliance on fossil fuels. Efforts are underway to improve the sustainability of rare earth element mining and processing, as well as to develop recycling processes for neodymium magnets to reduce environmental impact and resource dependency. The overall environmental benefit often depends on the specific application and lifecycle assessment, but their role in enabling sustainable technologies is significant.